Vacuum insulator with composite structure and preparation method thereof

A technology of vacuum insulation and composite structure, which is applied to insulators, electrical components, circuits, etc., can solve the problems of limited rise in vacuum surface flashover voltage, low voltage stability of insulators, and difficulty in meeting the needs of miniaturization of insulators. Inhibit the desorption process, low pressure stability, and improve the effect of flashover pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] see Figure 4 , the present invention also provides a method for preparing a vacuum insulator with a composite structure, comprising the following steps:

[0042] Step 1: Prepare an insulator whose overall shape is cylindrical according to the material and size requirements of the vacuum insulator with a composite structure to be prepared;

[0043] Step 2: Process the other end of the insulator prepared in step 1 to be connected to the anode into a truncated conical shape, and the included angle between the truncated conical busbar and the bottom surface of the large end of the truncated conical shape is 30° to 60°;

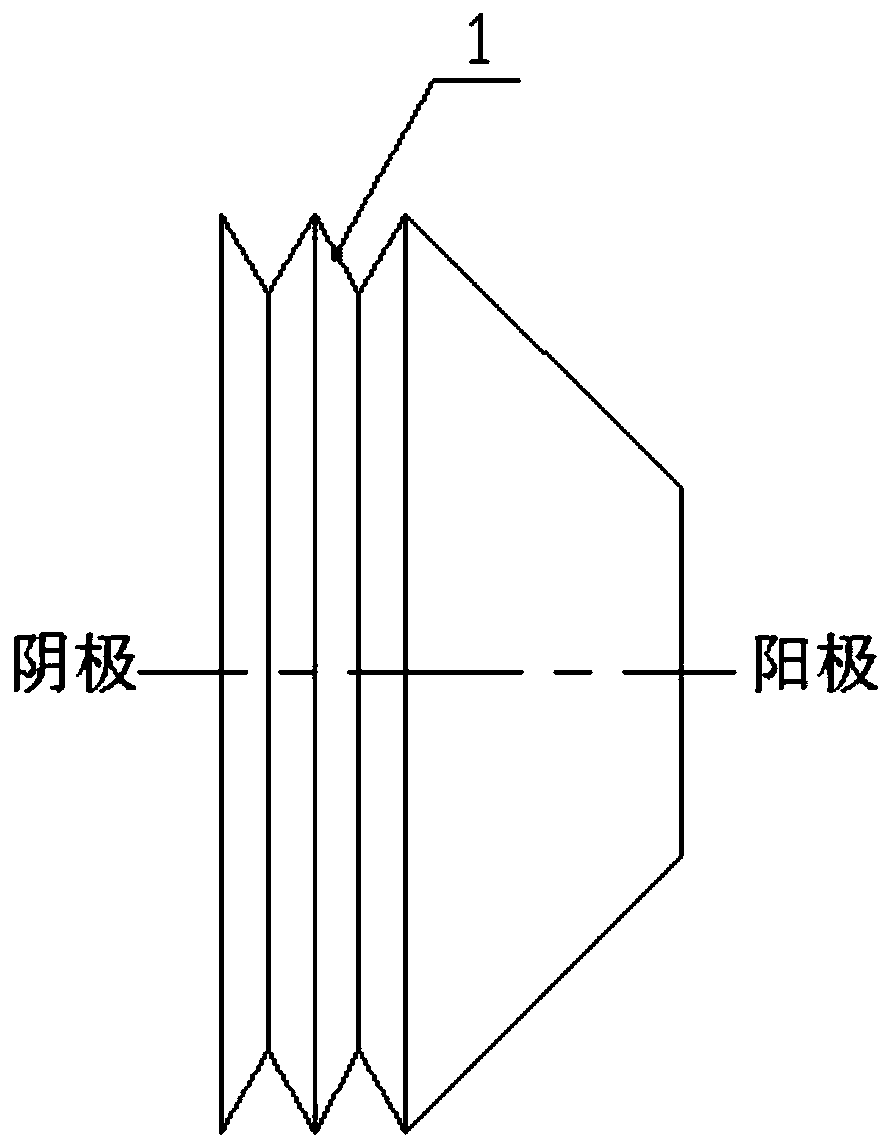

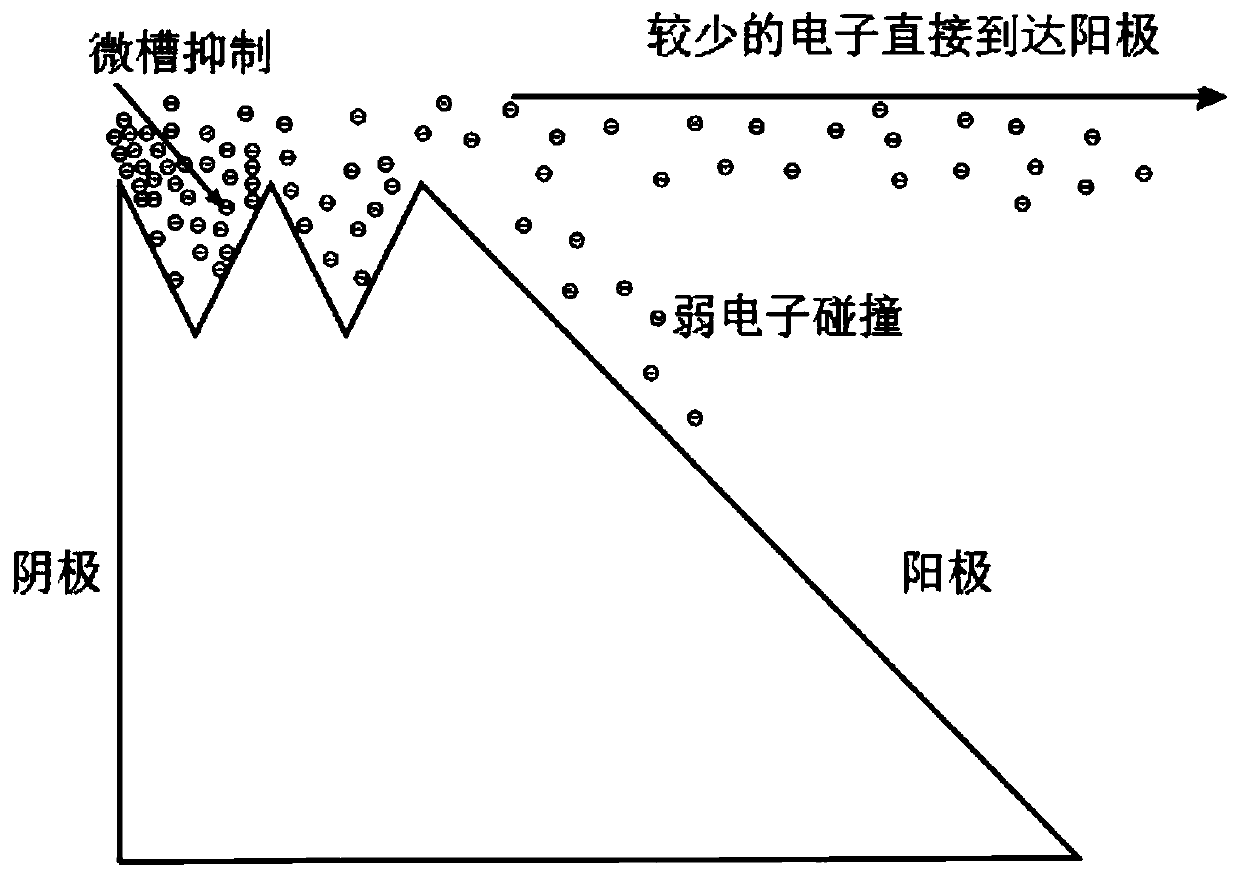

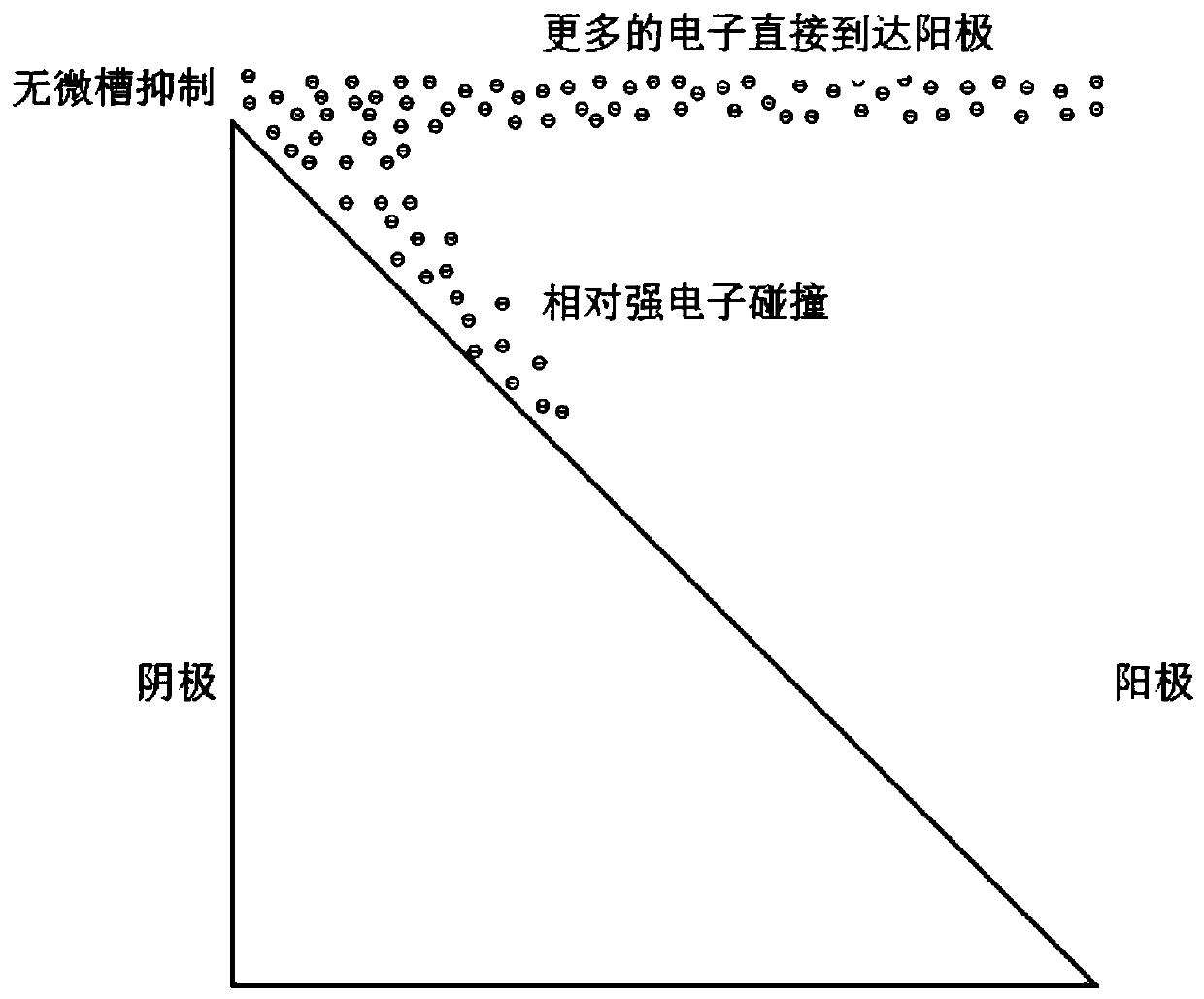

[0044] Step 3: Select the laser according to the material of the vacuum insulator with a composite structure to be prepared in step 1; turn on the laser, and process the width, depth and periodic size of the microgroove 1 according to the cylindrical side of the vacuum insulator with a composite structure to be prepared , set the laser parameters; by lase...

Embodiment 1

[0050] (1) Polymethyl methacrylate (PMMA) was selected as the experimental material, and an insulator with a cylindrical overall shape was prepared by mechanical processing. The diameter of the cylindrical shape was 30 mm, and the overall height was 5 mm;

[0051] (2) the insulator prepared in step 1 is used to process the other end connected with the anode into a truncated cone shape, the included angle between the busbar of the truncated cone shape and the bottom surface of the large end of the truncated cone shape is 60°, and the height of the truncated cone shape is 3mm;

[0052] (3) Select CO 2 Infrared laser (wavelength 10.64μm), turn on the laser, set the laser parameters, and etch two ring micro-coaxial with the cylinder on the side of the cylindrical end of the above-mentioned processed frustum-shaped insulator by laser rotary etching. Groove 1, two annular micro-grooves 1 are arranged in a periodic array along the axis of the cylinder, the cross-sectional shape of th...

Embodiment 2

[0055] (1) Polyetherimide (PEI) was selected as the experimental material, and an insulator with a cylindrical overall shape was prepared by mechanical processing. The diameter of the cylindrical shape was 30 mm, and the overall height was 5 mm;

[0056] (2) The insulator prepared in step 1 is used to process the other end connected to the anode into a truncated cone shape, the included angle between the busbar of the truncated cone shape and the bottom surface of the large end of the truncated cone shape is 30°, and the height of the truncated cone shape is 4.5mm;

[0057] (3) Select the ultraviolet laser, turn on the laser, set the laser parameters, and etch 25 ring-shaped micro-shaped coaxial with the cylinder on the side of the cylindrical end of the above-mentioned processed frustum-shaped insulator by laser rotary etching. Groove 1, 25 annular micro-grooves 1 are arranged in a periodic array along the axis of the cylinder. The cross-sectional shape of the micro-groove 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com