Method for continuously preparing large-aperture nitrocellulose film

A nitrocellulose membrane and nitrocellulose technology are applied in the field of continuous preparation of large-pore nitrocellulose membranes, which can solve problems such as non-hydrophilicity, non-uniform membrane structure, and inability to make larger pore sizes, and achieve membrane protein adsorption. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of Large Pore Nitrocellulose Membrane

[0020] Step 1: Prepare the membrane slurry and prepare the membrane liquid: Add co-solvent, surfactant, water and polymer material nitrocellulose into the reaction kettle for mixing. After mixing for 5.5 hours, add solvent and dissolve and stir at room temperature for 24 hours; then After defoaming and filtering, a uniform casting solution is obtained for subsequent use; the casting solution described in step 1 has a mass composition of 20% of cosolvent, 5.5% of surfactant, 5.5% of water, 22.5% of nitrocellulose, and solvent 30%. The co-solvent is ethanol, the surfactant is PEG400, and the solvent is acetone.

[0021] Step 2: cast the casting solution through a casting machine; the casting height in step 2 is 550um.

[0022] Step 3: The cast wet film is evaporated and formed through the evaporation section; the evaporation conditions in Step 3 are wind speed 2.6m / s, air temperature 40°, and humidity 50%. ...

Embodiment 2

[0025] Embodiment two: the impact on membrane cleanliness

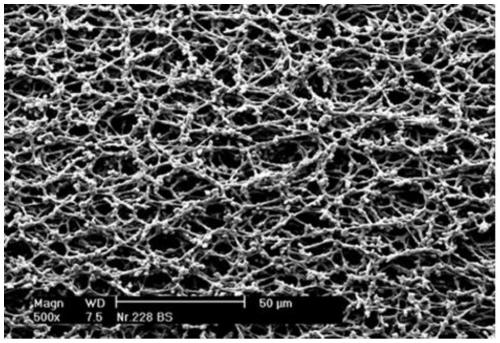

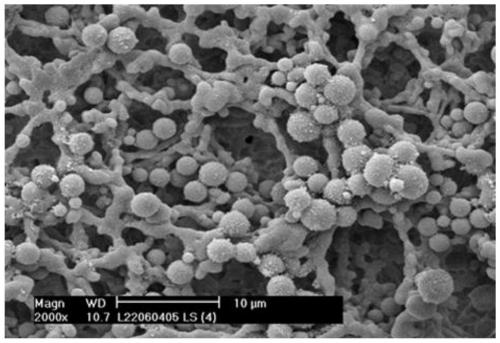

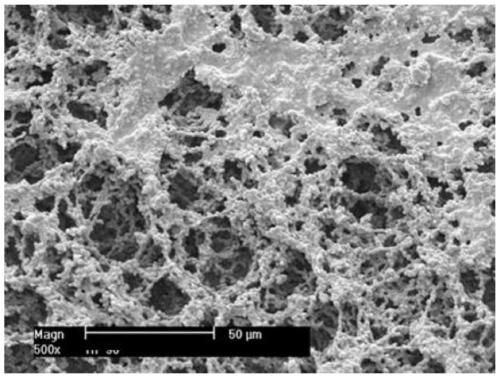

[0026] For the test results of formula and process on membrane cleanliness, see figure 1 , figure 2 , image 3 .

[0027] figure 1 It is the film pore diameter diagram at the production site according to the formula and process of the present application.

[0028] figure 2 It is the film pore diameter diagram of foreign brand A product.

[0029] image 3 It is the membrane pore diameter diagram of the domestic imitation product B.

[0030] The chart shows that the product is clean and has an open pore size diagram; the product of foreign brand A, due to the formula and process, the film produced has a spherical structure, which affects the performance of the film (adsorption, poor uniformity); domestic imitation products B. Due to the formula and process, the manufactured film has a lot of dust, which affects the performance of the film (adsorption, poor uniformity).

Embodiment 3

[0031] Example 3: Effects of Different Solvent Formulas and Component Proportions on Membrane Pore Size

[0032] The effects of different solvent formulations and composition ratios on the pore size of nitrocellulose membranes are shown in Table 1.

[0033] Table 1 Effects of different solvent formulations and composition ratios on the pore size of nitrocellulose membranes

[0034]

[0035] The above results show that, for nitrocellulose membranes, pore size has the greatest impact on performance.

[0036] Different nitrocellulose content and water content affect the pore size the most, and the final membrane performance is also different.

[0037] Co-solvents and solvents have little effect, choose the appropriate ones.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com