Preparation method of special-shaped hollow fiber ultrafiltration membrane, special-shaped PVDF hollow fiber ultrafiltration membrane and application of special-shaped PVDF hollow fiber ultrafiltration membrane

An ultrafiltration membrane, hollow technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of high surface tension, reduced mechanical strength, difficult to control the outer diameter and outer shape, etc., to achieve stable preparation process, guarantee Use effect, small size error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

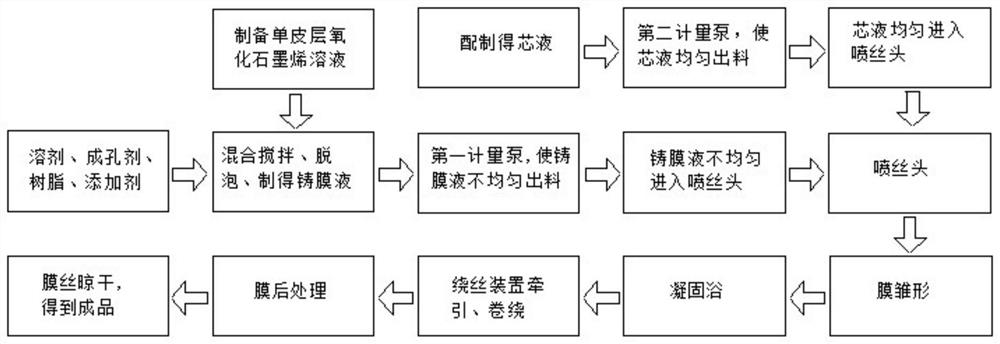

Method used

Image

Examples

preparation example Construction

[0054] The preparation of single-layer graphene oxide solution, organic solvent, polymer pore-forming agent and additives can also be selected according to the actual situation, and will not be repeated here.

[0055] A single-layer graphene oxide material is added to the membrane body. Through the large number of hydrophilic groups rich in single-layer graphene, the content of hydrophilic groups per unit range of the ultrafiltration membrane is increased, and the contact angle of the membrane surface is significantly reduced. This enables the ultrafiltration membrane to have long-term wettability, and improves the pollution resistance of the ultrafiltration membrane from another technical level.

[0056] In another specific embodiment, the core fluid contains the following substances in mass percentage: 20-50% organic solvent, 20-50% pure water, 5-20% methanol, and 5-10% acetone.

[0057] Wherein, the organic solvent is one or more of N,N-dimethylformamide, N,N-dimethylacetam...

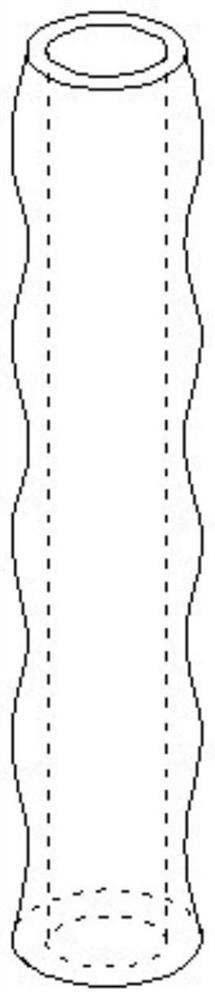

Embodiment 2

[0091] Embodiment 2 is the best use result obtained by combining each embodiment, and each embodiment is slightly different to the use effect of PVDF hollow fiber ultrafiltration membrane, mainly because in the same membrane shell space, under the same membrane area condition, the membrane The smaller the outer diameter of the filaments, the lower the membrane filling rate and the larger the free space. During the operation and cleaning process of the hollow fiber ultrafiltration membrane, the membrane filaments swing freely, rub against each other, vibrate and the turbulence on the membrane surface is more obvious. Pollutants are difficult to attach to the surface of the membrane, and under the same conditions, the thinner the wall thickness of the membrane, the smaller the backwash water resistance, and the easier it is to wash out the pollutants.

[0092] Although the differential pressure time and the chemical cleaning cycle of the ultrafiltration membrane (traditional memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com