Fluorine-silicon thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of elastomer materials, can solve problems such as the inability to obtain high molecular weight materials, the inability to effectively highlight the characteristics of silicone, and the low mechanical properties of materials, and achieve high surface migration efficiency, excellent hydrophobicity and Low temperature resistance performance, obvious effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Raw materials for preparing fluorosilicone type thermoplastic polyurethane elastomers, based on 100 parts by total weight, include:

[0050] a) diisocyanate: diphenylmethane diisocyanate, 35 parts;

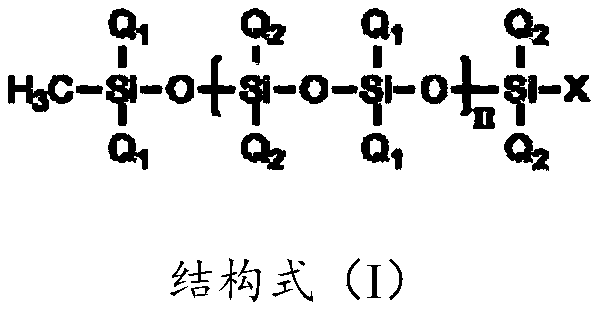

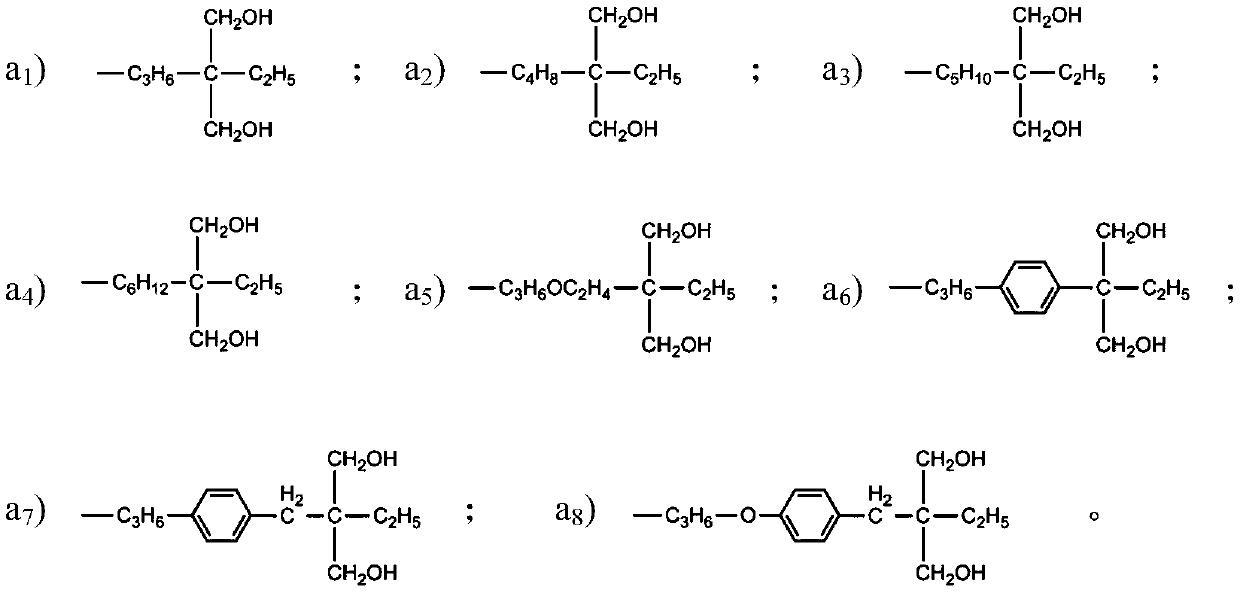

[0051] b) silicon-containing reactant: 6 parts, structural formula (I), wherein n is 10, Q 1 and Q 2 for -CH 3 , X is

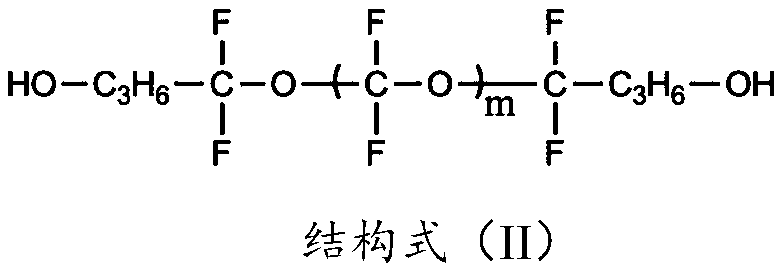

[0052] c) fluorine-containing reactant: 4 parts, structural formula (II), wherein m is 20;

[0053] d) macromolecular diol reactant: polytetrahydrofuran diol, number average molecular weight is 1000g / mol; 50 parts;

[0054] e) Chain extender: ethylene glycol, 5 parts.

[0055] The preparation method comprises the following steps:

[0056] 1) At a temperature of 100°C, add a mixture of macromolecular diol reactants and part of small molecule reactants to the diisocyanate, and wait until the reaction is complete to obtain NCO-terminated prepolymer I with an NCO content of 8.1 wt%. ;

[0057] 2), at the same temperature as step 1), separately and si...

Embodiment 2

[0136] Raw materials for preparing fluorosilicone type thermoplastic polyurethane elastomers, based on 100 parts by total weight, include:

[0137] a) diisocyanate: hexamethylene diisocyanate, 24 parts;

[0138] b) silicon-containing reactant: 12 parts, structural formula (I), wherein n is 25, Q 1 and Q 2 for -CH 3 , X is

[0139] c) Fluorine-containing reactant: 1 part, structural formula (II), wherein m is 10;

[0140] d) macromolecular diol reactant: polybutylene adipate diol, number average molecular weight is 4000g / mol; 58 parts;

[0141] e) Chain extender: 1,4-butanediol, 5 parts.

[0142] The preparation method comprises the following steps:

[0143] 1), at a temperature of 110° C., first add a mixture of macromolecular diol reactants and part of small molecule reactants to the diisocyanate, and wait until the reaction is complete to obtain NCO-terminated prepolymer I with an NCO content of 6 wt %;

[0144] 2), at the same temperature as step 1), separately and...

Embodiment 3

[0149] Raw materials for preparing fluorosilicone type thermoplastic polyurethane elastomers, based on 100 parts by total weight, include:

[0150] a) Diisocyanate: 1,4-cyclohexane diisocyanate, 40 parts;

[0151] b) silicon-containing reactant: 7 parts, structural formula (I), wherein n is 5, Q 1 and Q 2 for X is

[0152] c) fluorine-containing reactant: 10 parts, structural formula (II), wherein m is 60;

[0153] d) Macromolecular diol reactant: polycarbonate diol, number average molecular weight is 1500g / mol; 33 parts;

[0154] e) Chain extender: 1,4-cyclohexanediol, 10 parts.

[0155] The preparation method comprises the following steps:

[0156] 1), at a temperature of 140° C., first add a mixture of macromolecular diol reactants and part of small molecule reactants to the diisocyanate, and wait until the reaction is complete to obtain NCO-terminated prepolymer I, with an NCO content of 4 wt %;

[0157] 2), at the same temperature as in step 1), separate and sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com