Supported honeycomb catalyst, and preparation method and application thereof

A honeycomb catalyst and supported technology, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of difficult to meet acrylonitrile and high reaction temperature, and achieve simple preparation process, low energy consumption and high catalytic performance The effect of activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Mesoporous γ-Al with narrow pore distribution is first prepared by hydrothermal synthesis (conventional hydrothermal synthesis belongs to the prior art) 2 o 3 , Weigh 9.6648g Cu(NO) 3 ·3H2 O (chemically pure reagent), 1.6987g AgNO 3 (chemically pure reagent) was dissolved in 98g of water to make an impregnation solution, in which the molar ratio of Cu to Ag was 4:1, and then weighed γ-Al 2 o 3 6.2g was placed in the impregnating solution, stirred thoroughly, dried at 120°C for 12 hours, and calcined at 600°C for 4 hours to obtain M / γ-Al 2 o 3 active ingredient. Put it, 3.0g of pseudo-boehmite and 1.0g of alumina sol into a ball mill jar, 30g of water, and ball mill for 3 hours at a speed of 500r / min to obtain a slurry. Put 1mL cordierite carrier into the slurry and soak for 3min, take it out and drain, dry overnight at 200°C, calcinate at 650°C for 4h to prepare the catalyst, and cool to obtain the required monolithic structure honeycomb ceramic catalyst.

[009...

Embodiment 2~ Embodiment 6

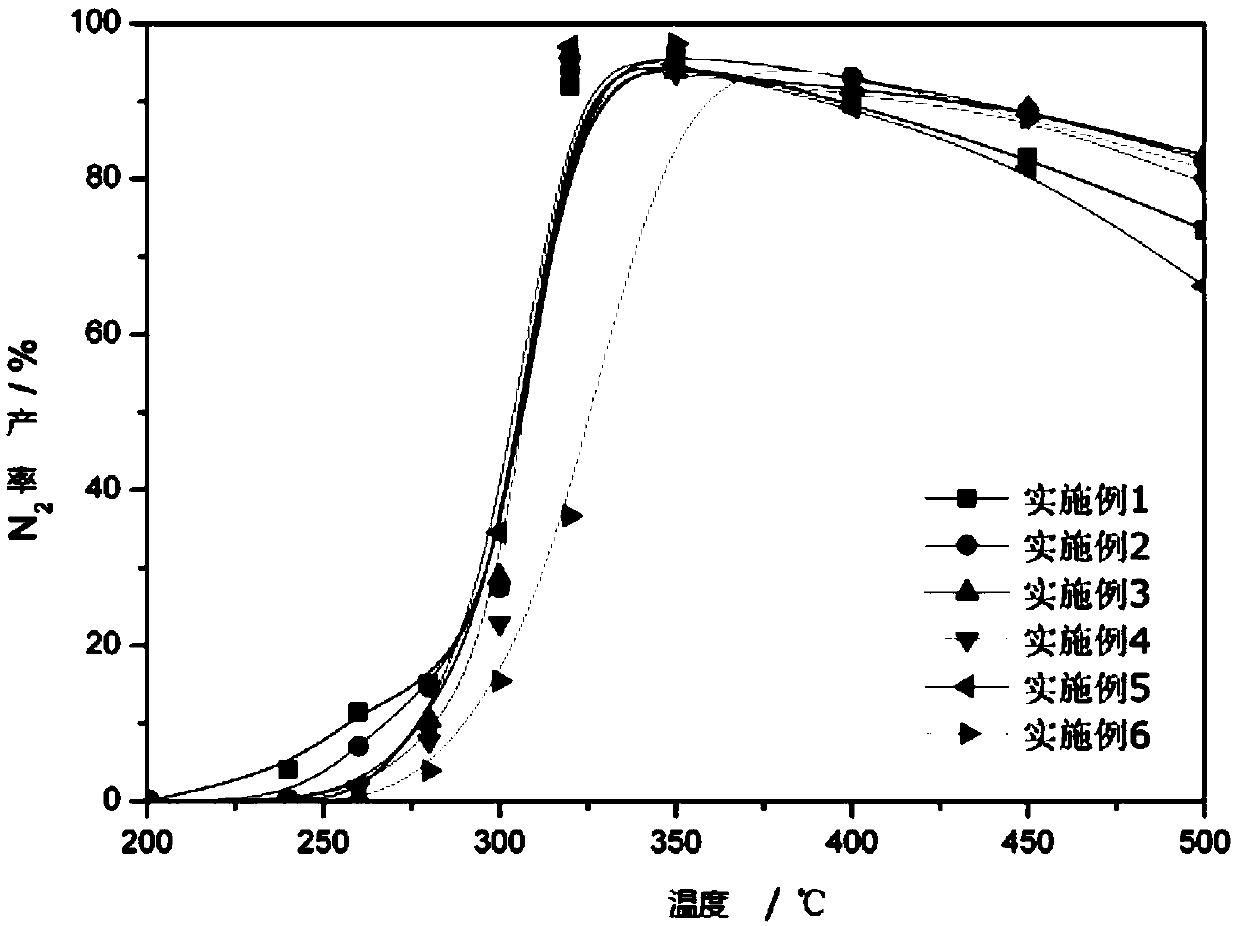

[0100] The catalyst Cu that adopts and Ag load capacity are different, from embodiment 2 to embodiment 6 the mol ratio of Cu and Ag is respectively 4:2, 4:3, 4:4, 5:2 and 3:3, other conditions and Embodiment 1 is all the same. Embodiment 2~Example 6 Catalyst evaluation operation is the same as embodiment 1, and evaluation result is as follows figure 1 shown.

Embodiment 7

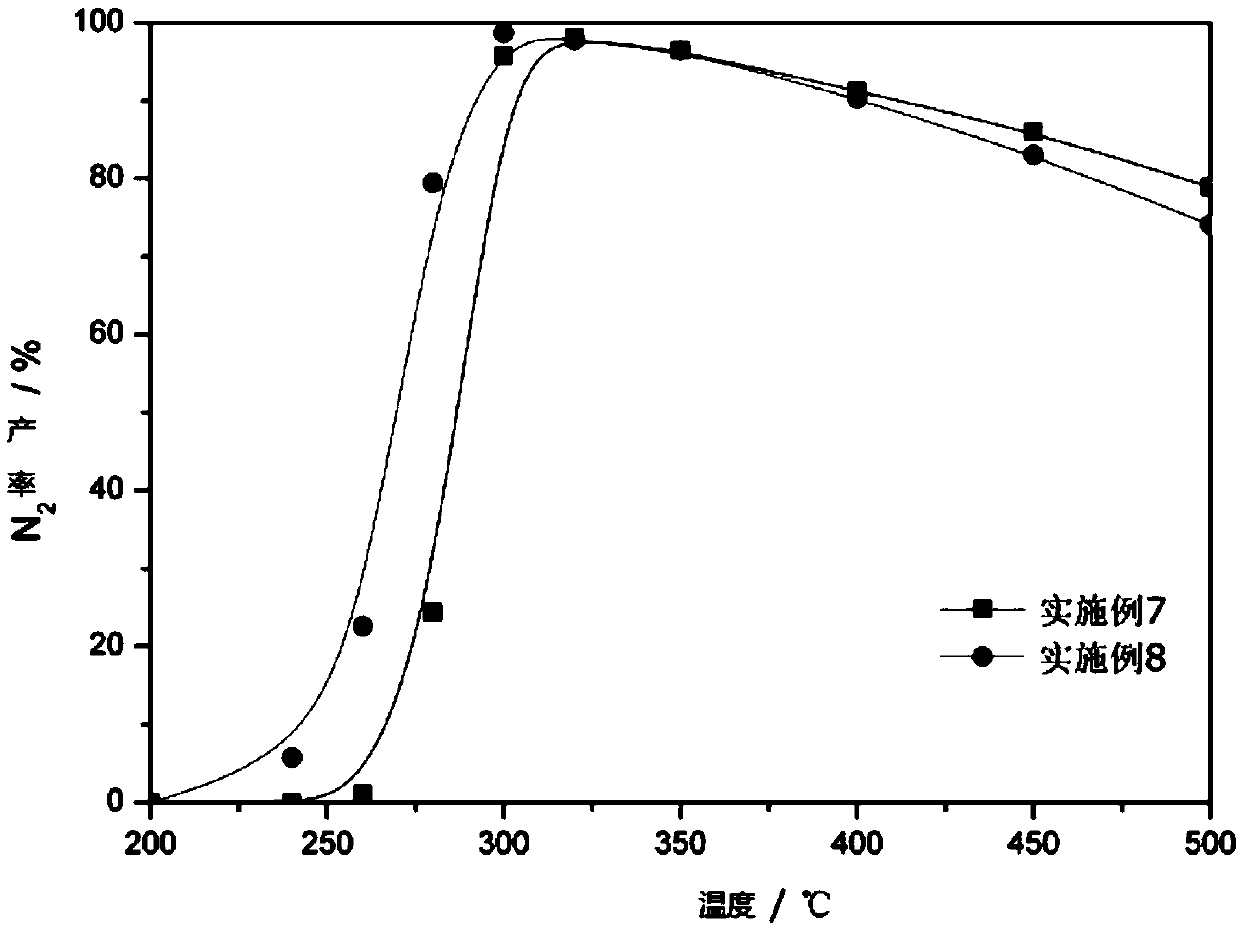

[0102] First synthesize mesoporous γ-Al with narrow pore distribution by sol-gel method (prepared according to the method in patent CN104399470A) 2 o 3 , 9.6648g Cu(NO 3 ) 3 ·3H 2 O (chemically pure reagent), 1.6987g AgNO 3 (Chemical pure reagent) 4.3412gCe(NO 3 ) 3 ·6H 2 O (chemically pure reagent), 6.2g γ-Al 2 o 3 , 3.0g pseudo-boehmite, 1.0g alumina sol and 30g water were put into a ball mill together, wherein the mass percentages of Cu, Ag and Ce were 4:2:1, and the remaining catalyst preparation conditions and catalyst evaluation conditions were the same as in Example 1. Evaluation results such as figure 2 as shown, figure 2 shows that after adding 1% cerium in the catalyst coating mass percentage, N 2 The selectivity of cerium has a greater improvement at lower temperature (300 °C), indicating that cerium can lower the temperature at which acrylonitrile is completely converted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com