Preparation and application of porous composite material electrocatalyst based on bimetallic macrocyclic compound

A technology of porous composite materials and macrocyclic compounds, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as difficult large-scale application and complicated preparation process, achieve mild material synthesis conditions, simplify the preparation process, and reduce particle agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] At room temperature (25°C), prepare 10mL of 10mM 2-methylimidazole aqueous solution and ultrasonically homogenize; prepare 10mL of 2.5mM zinc acetate aqueous solution and ultrasonically homogenize; dissolve 2mL containing 22.5mg porphyrin iron and 7.5mg porphyrin cobalt in In 2mL of N,N-dimethylformamide (DMF) solution, ultrasonically uniform;

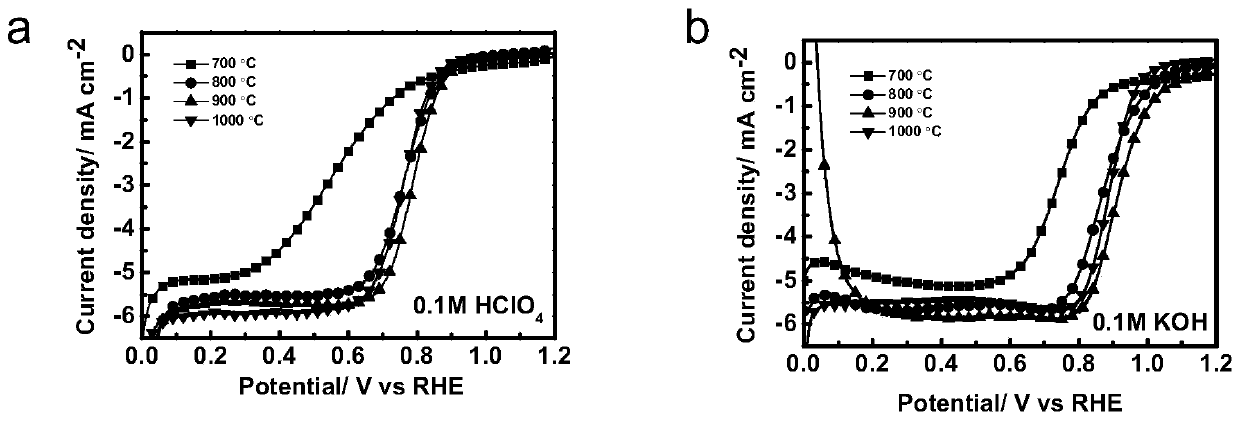

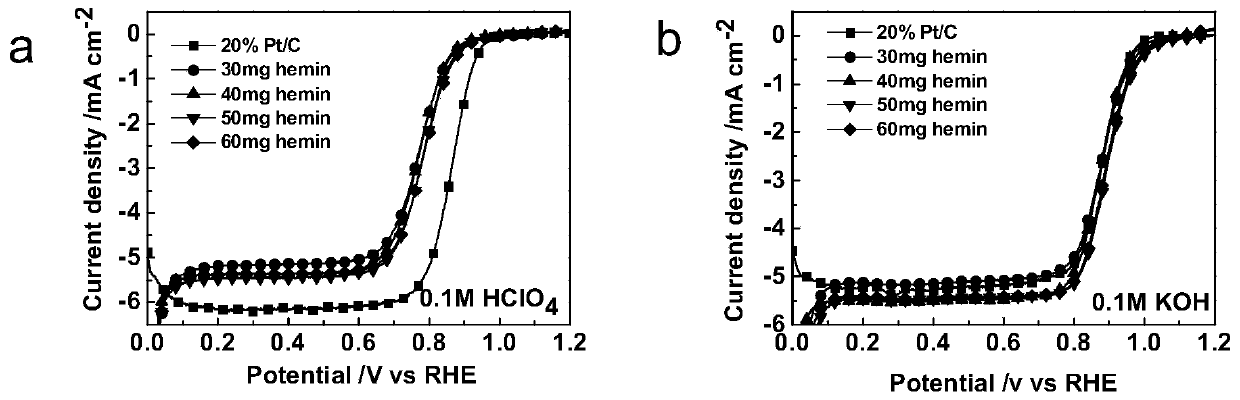

[0048] Pour 2 mL of N,N-dimethylformamide (DMF) solution containing 22.5 mg of porphyrin iron and 7.5 mg of porphyrin cobalt into 10 mL of 10 mM 2-methylimidazole aqueous solution, sonicate for 15 min, and then add 10 mL of 2.5 mM The zinc acetate aqueous solution was poured into the above-mentioned mixed solution which was continuously stirred, reacted at normal pressure for 8 hours, suction filtered, and dried; the dried sample was ground to obtain a metal macrocyclic compound and an organic porous composite material, and the composite material was placed in a tube furnace in argon atmosphere, heat up to 900°C at a rate of 2-1...

Embodiment 2

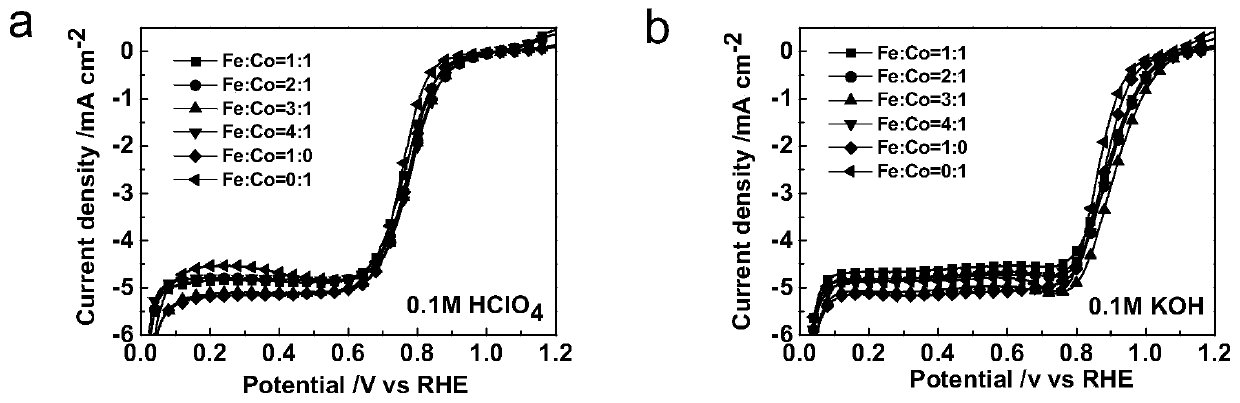

[0052] (different from metal macrocyclic compound porphyrin iron and porphyrin cobalt ratio in embodiment 1, other steps are identical):

[0053] At room temperature (25°C), pour 2 mL of N,N-dimethylformamide (DMF) solution containing 20 mg of porphyrin iron and 10 mg of porphyrin cobalt into 10 mL of 10 mM 2-methylimidazole aqueous solution, and sonicate for 15 min. Then pour 10mL of 2.5mM zinc acetate aqueous solution into the above-mentioned mixed solution under constant stirring, react at normal pressure for 8h, filter with suction, and dry. Then heat treatment at 900° C. for 2 hours under an argon atmosphere to obtain an electrocatalyst Fe:Co=2:1-900° C.

Embodiment 3-4

[0055] In the preparation method, the ratio of the metal macrocyclic compound porphyrin iron and porphyrin cobalt is different from that in Example 1, and the other steps are the same to obtain the electrocatalyst Fe:Co=1:1, Fe:Co=4:1.

[0056] like figure 2 As shown in a and b, when Fe:Co=1:1, Fe:Co=2:1, Fe:Co=3:1, Fe:Co=4:1, no matter in acidic or alkaline environment, the catalyst Both have high half-wave potentials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com