Silicon-based substrate, substrate base plate and manufacturing method thereof, and photoelectric device

A substrate substrate and substrate technology, applied in the field of electronic technology applications, can solve problems such as lattice mismatch, difficulty in forming silicon-based substrates of group III and V materials, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

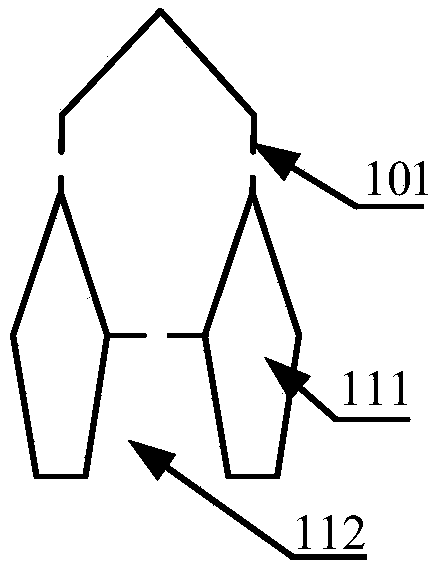

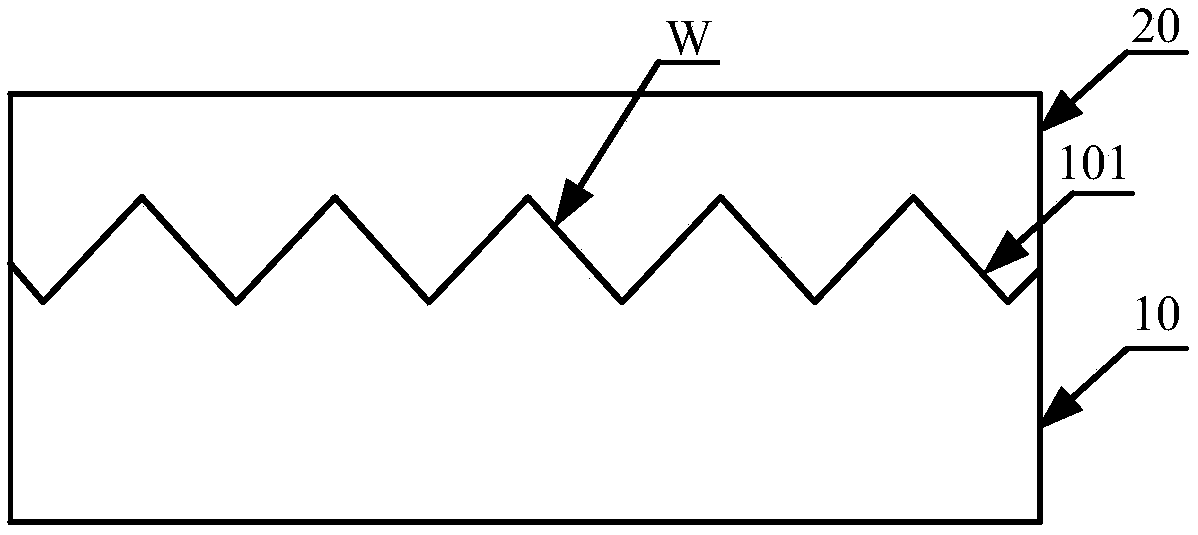

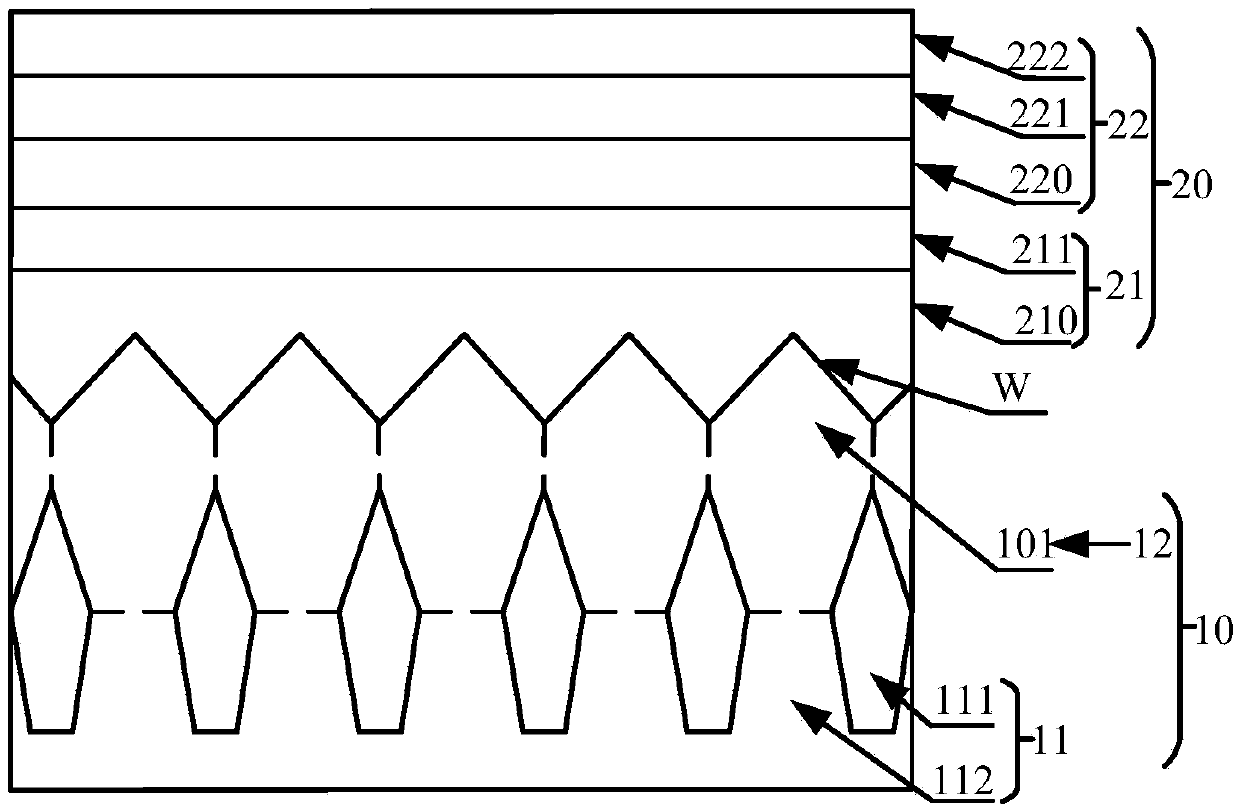

[0086] The embodiments of the present application relate to the improvement of silicon-based substrates and base substrates manufactured based on the silicon-based substrates. Silicon belongs to the cubic crystal system. In the embodiments of the present application, silicon wafers with multiple crystal faces are involved. 100) Silicon wafers with crystal planes, silicon wafers with silicon (110) crystal planes, and silicon wafers with silicon (111) crystal planes. In order to facilitate readers' understanding, these silicon wafers are introduced as follows:

[0087] A silicon wafer with a silicon (100) crystal plane is also called a silicon wafer (100), [100] is the crystal orientation index, and the normal of the silicon (100) crystal plane is parallel to the [100] crystal orientation, that is to say (100) ) The crystal plane is perpendicular to the [100] crystal direction.

[0088] A silicon wafer with a silicon (110) crystal plane is also called a silicon wafer (110). [110] is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com