Monitoring feedback system for server cabinet production

A technology for server cabinets and monitoring feedback, which is applied in general control systems, control/regulation systems, and program control in sequence/logic controllers. It can solve the problems of insufficient detection types and achieve buffer losses and protect service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

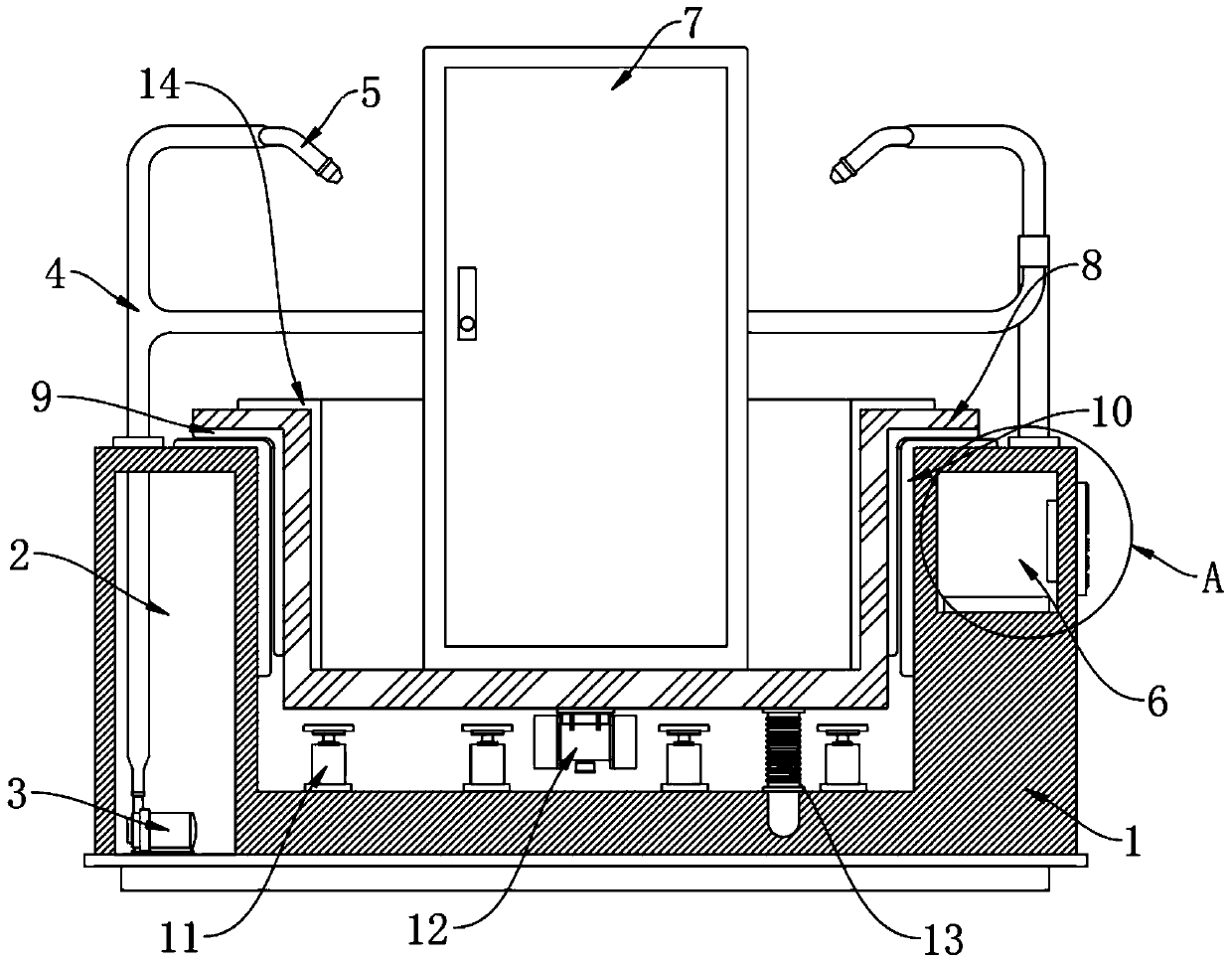

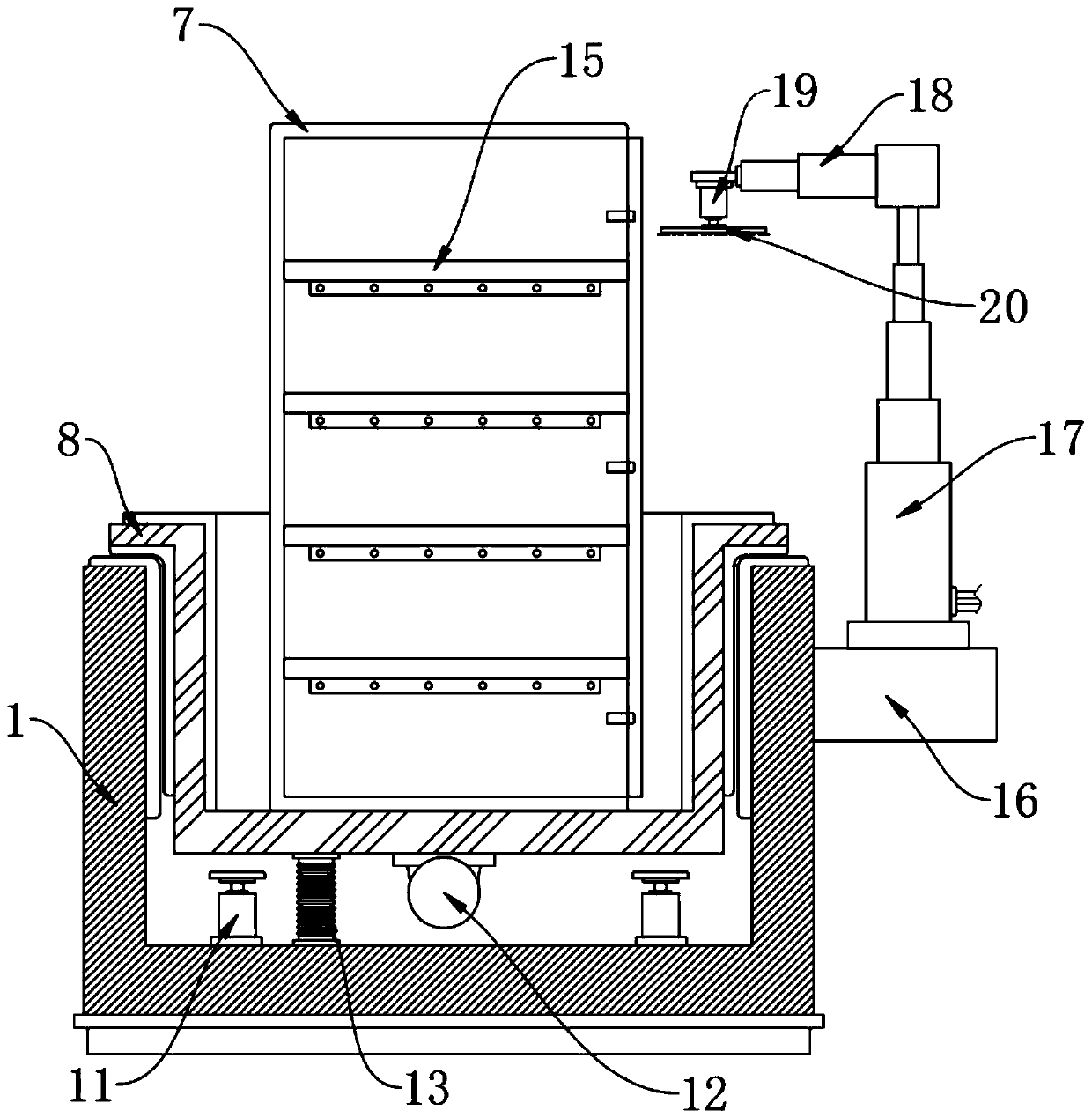

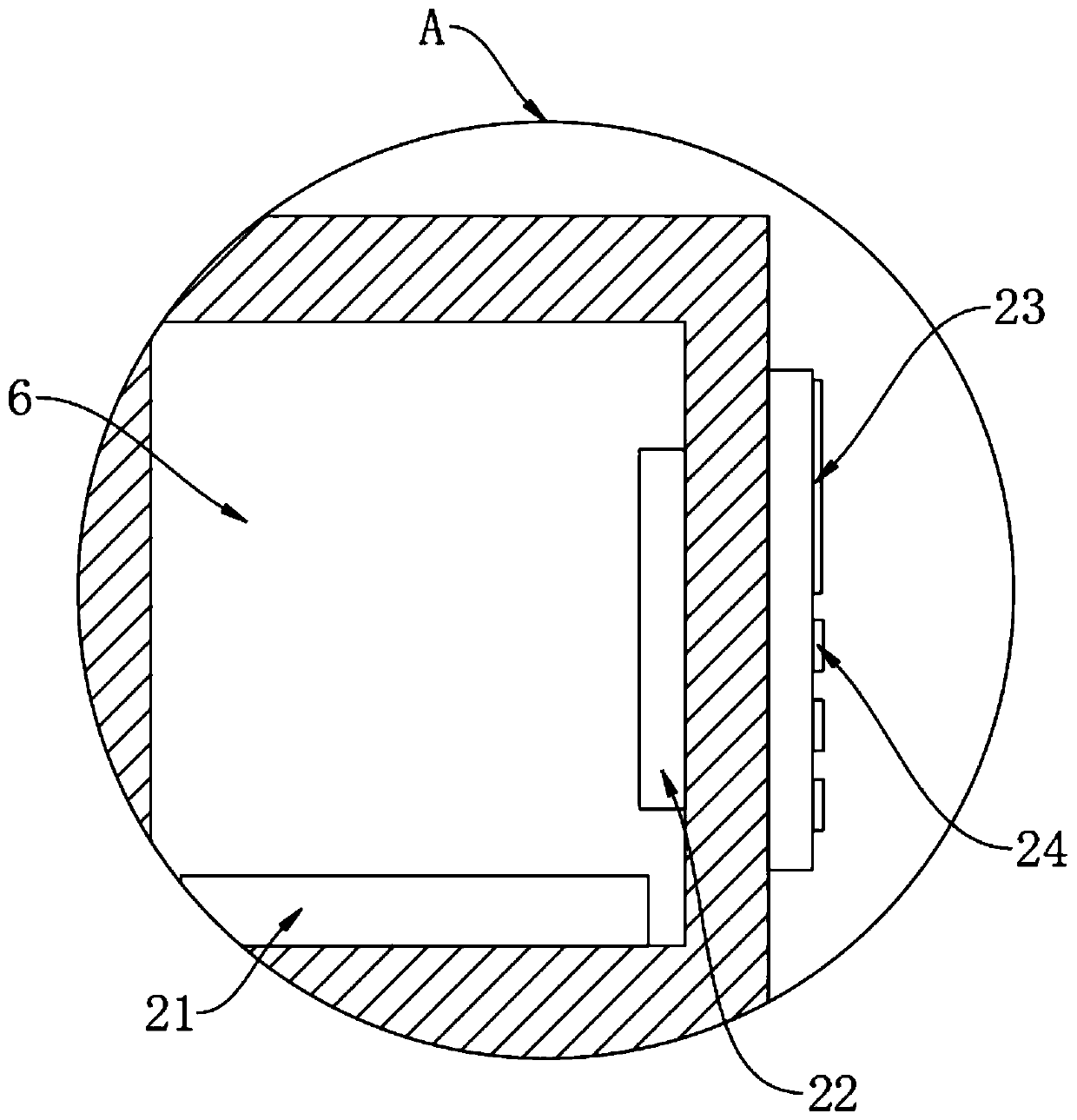

[0021] see Figure 1-4 , an embodiment provided by the present invention: a monitoring and feedback system for the production of server cabinets, including a housing 1, a cabinet cavity 8 is provided in the middle of the housing 1, and a cabinet 7 is provided inside the cabinet cavity 8 , Both sides of the cabinet cavity 8 are provided with a water distribution pipe 4, and one end of the water distribution pipe 4 is sealed and connected with a discharge spray 5, and the discharge discharge 5 realizes the spraying of water, thereby realizing the detection of the waterproof performance.

[0022] Further, a vibrating motor 12 is fixedly installed below the cabinet cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com