Stainless steel corrosive for fuel cell bipolar plate and metallographic phase preparation method

A fuel cell and bipolar plate technology, applied in the preparation of test samples, etc., can solve the problems of complex solution composition and preparation process, long standing time of corrosion solution, and difficulty in preparing metallographic samples, etc., to achieve metallographic structure Uniform and clear, less harmful, easy to prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

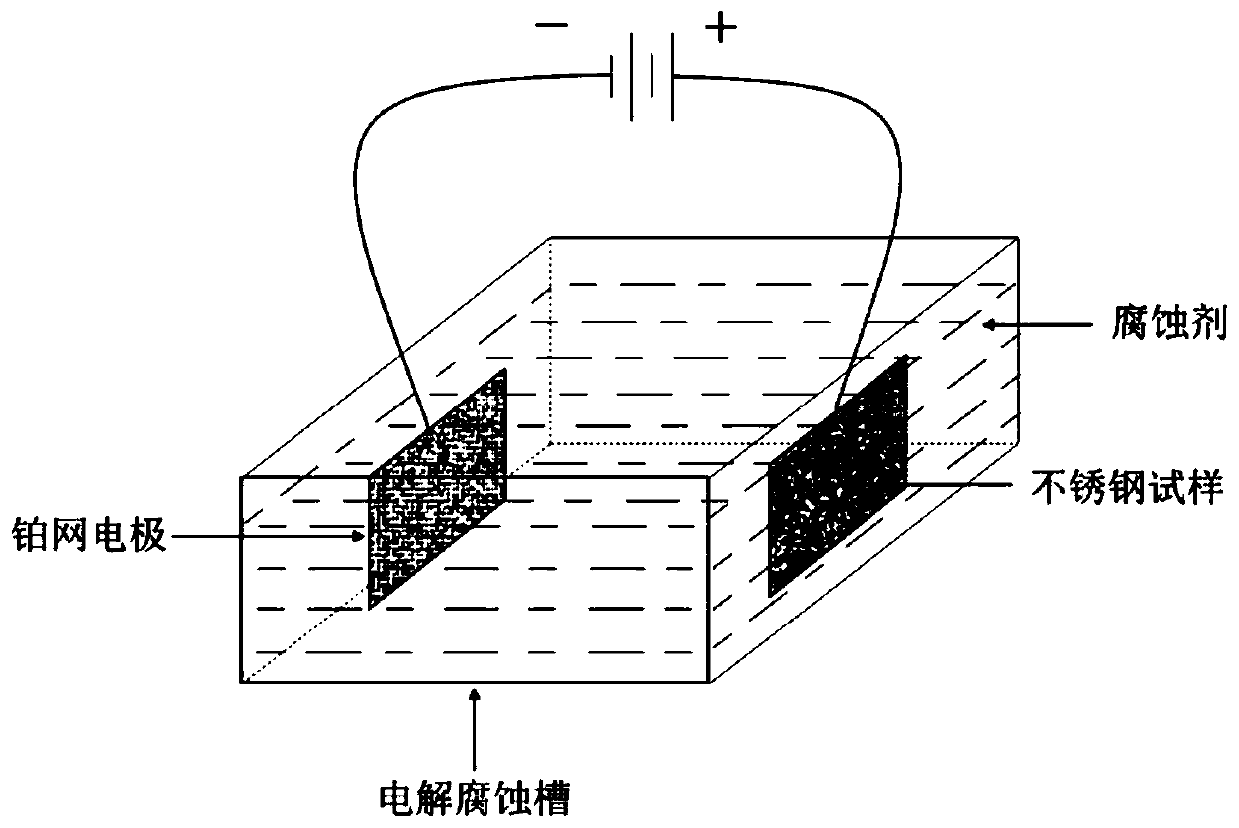

[0046] A metallographic preparation method of stainless steel for a fuel cell bipolar plate, using the above-mentioned corrosive agent, comprising the following steps:

[0047] (1) Sample preparation: the fuel cell bipolar plate is sampled, prepared, cleaned and dried with stainless steel;

[0048] (II) Corrosive agent preheating: preheating the corrosive agent, and the preheating temperature is controlled at 40-90°C;

[0049] (III) Corrosion: take the sample and the corrosion-resistant conductive material as anode and cathode respectively, insert them into the preheated etchant, apply a voltage of 1.0-2.0V on both ends of the sample and the corrosion-resistant conductive material, and corrode for 0.5-6min ;

[0050] (IV) Take out the sample, wash and dry it.

[0051] In the sampling process of preferred step (I) among the present invention, adopt shearing machine, cutting machine or wire cutting method to intercept the sample whose side length is greater than or equal to 1c...

Embodiment 1

[0064] (1) Preparation of corrosive agent: preparation of 2.7% H 2 SO 4 +0.5% HF (volume percentage, the same below) deionized water etching solution 500ml;

[0065] (2) Corrosive agent preheating: put the corrosive agent in a constant temperature water bath for preheating, and the preheating temperature is controlled at 80°C;

[0066] (3) Sampling: use a shearing machine to intercept a sample with a side length of 2.5 cm;

[0067] (4) Cleaning and drying: first clean with deionized water, then clean with alcohol, and dry with a hair dryer after cleaning;

[0068] (5) Corrosion: Place the anode and cathode of the stainless steel sample and the corrosion-resistant conductive material in the preheated corrosive agent respectively, apply a voltage of 1.2V, and corrode for 2 minutes;

[0069] (6) Cleaning and drying: first clean with water, then with alcohol, and dry with a hair dryer after cleaning;

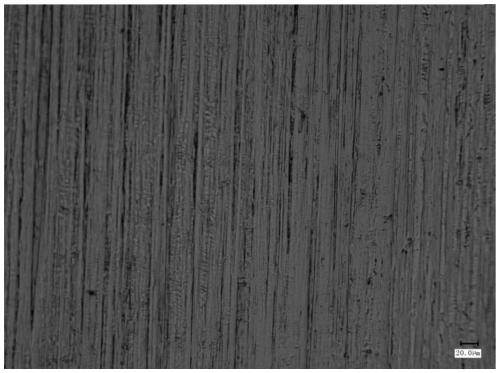

[0070] (7) Microscopic observation: the corroded sample was observed under ...

Embodiment 2

[0072] (1) Preparation of corrosive agent: preparation of 2.7% H 2 SO 4 +0.5% HF deionized water etching solution 500ml;

[0073] (2) Corrosive agent preheating: put the corrosive agent in a constant temperature water bath for preheating, and the preheating temperature is controlled at 80°C;

[0074] (3) Sampling: use a shearing machine to intercept a sample with a side length of 2.5 cm;

[0075] (4) Cleaning and drying: first clean with deionized water, then clean with alcohol, and dry with a hair dryer after cleaning;

[0076] (5) Corrosion: Place the anode and cathode of the stainless steel sample and the corrosion-resistant conductive material in the preheated corrosive agent respectively, apply a voltage of 1.2V, and corrode for 4 minutes;

[0077] (6) Cleaning and drying: first clean with water, then with alcohol, and dry with a hair dryer after cleaning;

[0078] (7) Microscopic observation: the corroded sample was observed under a microscope. Surface topography se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com