Anti-emulsion demulsifier for acid fracturing and preparation method thereof

A technology of acidified fracturing and demulsifier, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult to meet the rapid flowback of working fluid, achieve good application and promotion value, reduce costs, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take co-solvent methanol, add sodium perfluorononenyloxybenzene sulfonate, polyoxyethylene, polyethylene glycol stearyl ether, alkylphenol polyoxyethylene ether and raise the temperature to 30°C, stir for 1.5h, add purified water, Keep the temperature at 30°C, continue to stir for 1.5h, add a stabilizer, keep the temperature at 30°C, continue to stir for 01.5h to obtain an anti-emulsion demulsifier.

[0026] Wherein the added purified water weight is 7 times of the weight of sodium perfluorononenyloxybenzene sulfonate;

[0027] The weight ratio of the raw materials perfluorononenyloxybenzene sulfonate sodium, polyoxyethylene, polyethylene glycol stearyl ether, and alkylphenol polyoxyethylene ether is 4:7:14:2.

[0028] Wherein the stabilizer is octylphenol polyoxyethylene ether OP-15.

[0029] Wherein the weight ratio of co-solvent alcohols to sodium perfluorononenyloxybenzene sulfonate is 5:1.

[0030] Wherein the weight of the stabilizer octylphenol polyoxyethylene ...

Embodiment 2

[0032] Take ethylene glycol as a cosolvent, add sodium perfluorononenyloxybenzenesulfonate, polyoxyethylene, polyethylene glycol stearyl ether, and alkylphenol polyoxyethylene ether and raise the temperature to 70°C, stir for 0.5h, add purification water, keep the temperature at 70°C, continue to stir for 0.5h, add a stabilizer, keep the temperature at 70°C, continue to stir for 0.5h to obtain an anti-emulsion demulsifier.

[0033] Wherein the added purified water weight is 8 times of the weight of sodium perfluorononenyloxybenzene sulfonate;

[0034] The weight ratio of the raw materials perfluorononenyloxybenzene sulfonate sodium, polyoxyethylene, polyethylene glycol stearyl ether, and alkylphenol polyoxyethylene ether is: 6:9:16:6.

[0035] Wherein the stabilizer is octylphenol polyoxyethylene ether OP-15.

[0036] Wherein the weight ratio of co-solvent alcohols to sodium perfluorononenyloxybenzene sulfonate is 7:1.

[0037] Wherein the weight of the stabilizer octylpheno...

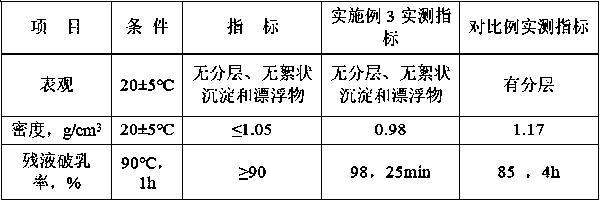

Embodiment 3

[0039] Take co-solvent ethanol, add sodium perfluorononenyloxybenzene sulfonate, polyoxyethylene, polyethylene glycol stearyl ether, and alkylphenol polyoxyethylene ether, heat up to 50°C, stir for 1 hour, add purified water, keep The temperature is 50°C, continue to stir for 1 hour, add a stabilizer, keep the temperature at 50°C, and continue to stir for 1 hour to obtain an anti-emulsion demulsifier.

[0040] Wherein the added purified water weight is 7.5 times of the weight of sodium perfluorononenyloxybenzene sulfonate;

[0041] The weight ratio of the raw materials perfluorononenyloxybenzene sulfonate sodium, polyoxyethylene, polyethylene glycol stearyl ether, and alkylphenol polyoxyethylene ether is: 5:8:15:4.

[0042] Wherein the auxiliary solvent is alcohols: methanol, ethanol or ethylene glycol.

[0043] Wherein the stabilizer is octylphenol polyoxyethylene ether OP-15.

[0044] Wherein the weight ratio of co-solvent alcohols to sodium perfluorononenyloxybenzene sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com