Preparation method of high-coverage water-based lead-free environment-friendly high-temperature glass ink

A high-temperature glass, water-based technology, used in inks, household appliances, applications, etc., can solve problems such as poor tolerance, orange peel, pinholes, etc., and achieve high batch stability, low VOC, and excellent acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

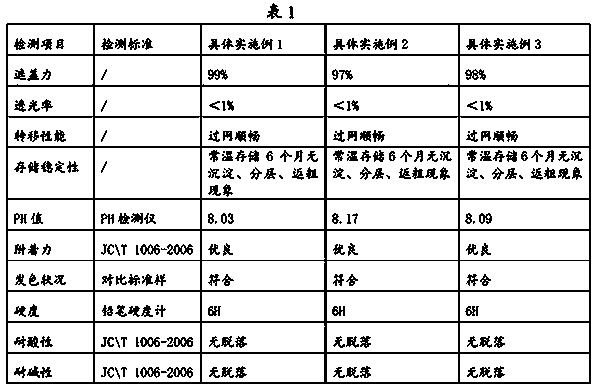

Embodiment 1

[0038] A black water-based lead-free environmentally friendly high-temperature glass ink includes two components: a main agent and a diluent. The first component of the main agent includes the following raw materials in parts by weight: 59 parts of lead-free environmentally friendly glass powder, 25 parts of water-based varnish, copper 15.8 parts of chrome black, 0.2 part of tank stabilizer, wherein, the lead-free environmental protection glass powder in the first component main agent comprises the raw material of following parts by weight: 34 parts of silicon dioxide, 3 parts of aluminum oxide, 19 parts of bismuth trioxide 6 parts, 6 parts of zinc oxide, 20 parts of boric acid, 5 parts of potassium carbonate, 5 parts of sodium carbonate, 7 parts of titanium dioxide, 1 part of lanthanum oxide, the second component diluent comprises the raw material of following weight part: 4 parts of acrylic acid polymer, two parts 96.6 parts of ethylene glycol butyl ether, 0.4 parts of transf...

Embodiment 2

[0048] A yellow water-based lead-free environmentally friendly high-temperature glass ink includes two components: a main agent and a diluent. The first component of the main agent includes the following raw materials in parts by weight: 47 parts of lead-free environmentally friendly glass powder, 25 parts of water-based varnish, bismuth 13 parts of yellow, 14.8 parts of titanium dioxide, 0.2 part of tank stabilizer, wherein, the lead-free environmental protection glass powder in the main agent of the first component includes the following raw materials in parts by weight: 39 parts of silicon dioxide, 2 parts of aluminum oxide, three 20 parts of bismuth oxide, 5 parts of zinc oxide, 15 parts of boric acid, 5 parts of potassium carbonate, 5 parts of sodium carbonate, 10 parts of titanium dioxide, 3 parts of lanthanum oxide, the second component diluent includes the following raw materials in parts by weight: acrylic acid polymer 4 parts, 96.6 parts of diethylene glycol butyl eth...

Embodiment 3

[0058] A water-based lead-free environmentally friendly high-temperature glass ink includes two components: a main agent and a diluent. The first component of the main agent includes the following raw materials in parts by weight: 70 parts of lead-free environmentally friendly glass powder, 15 parts of water-based varnish, iron-zinc 5.8 parts of chrome brown, 9 parts of titanium dioxide, 0.2 parts of tank stabilizer, wherein, the lead-free environmental protection glass powder in the main agent of the first component includes the following raw materials in parts by weight: 38 parts of silicon dioxide, 3 parts of aluminum oxide, 16 parts of bismuth trioxide, 6 parts of zinc oxide, 17 parts of boric acid, 5 parts of potassium carbonate, 5 parts of sodium carbonate, 8 parts of titanium dioxide, 2 parts of lanthanum oxide, the second component diluent includes the following raw materials in parts by weight: acrylic acid polymerization 4 parts, 96.6 parts of diethylene glycol butyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com