Light metal borohydride/carbon loaded nanometer vanadium trioxide composite hydrogen storage material and preparation method thereof

A technology of borohydride and hydrogen storage materials, applied in chemical instruments and methods, non-metallic elements, hydrogen, etc., can solve the problem of reduced theoretical hydrogen storage capacity, achieve high porosity characteristics, facilitate dispersion, and high-efficiency catalysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

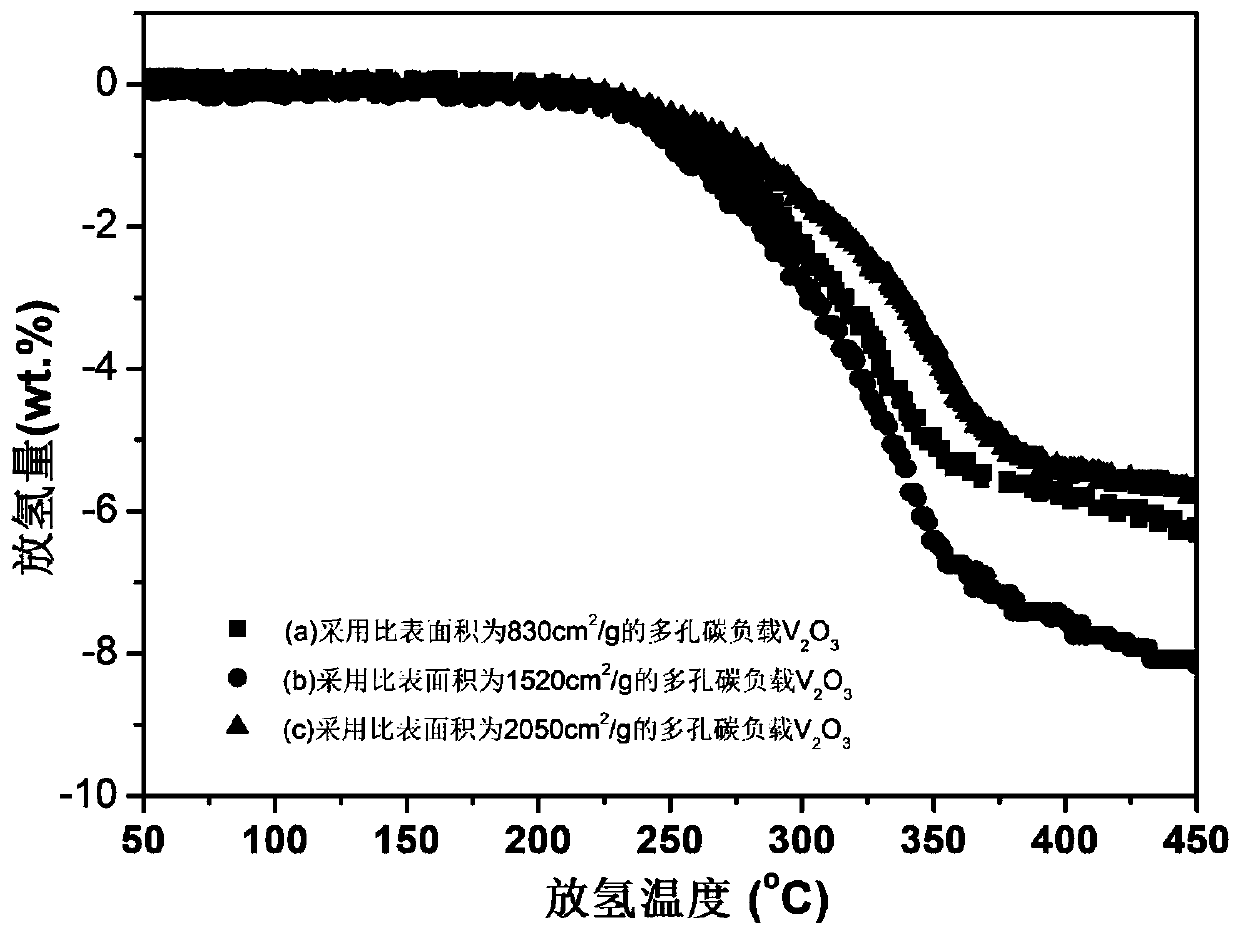

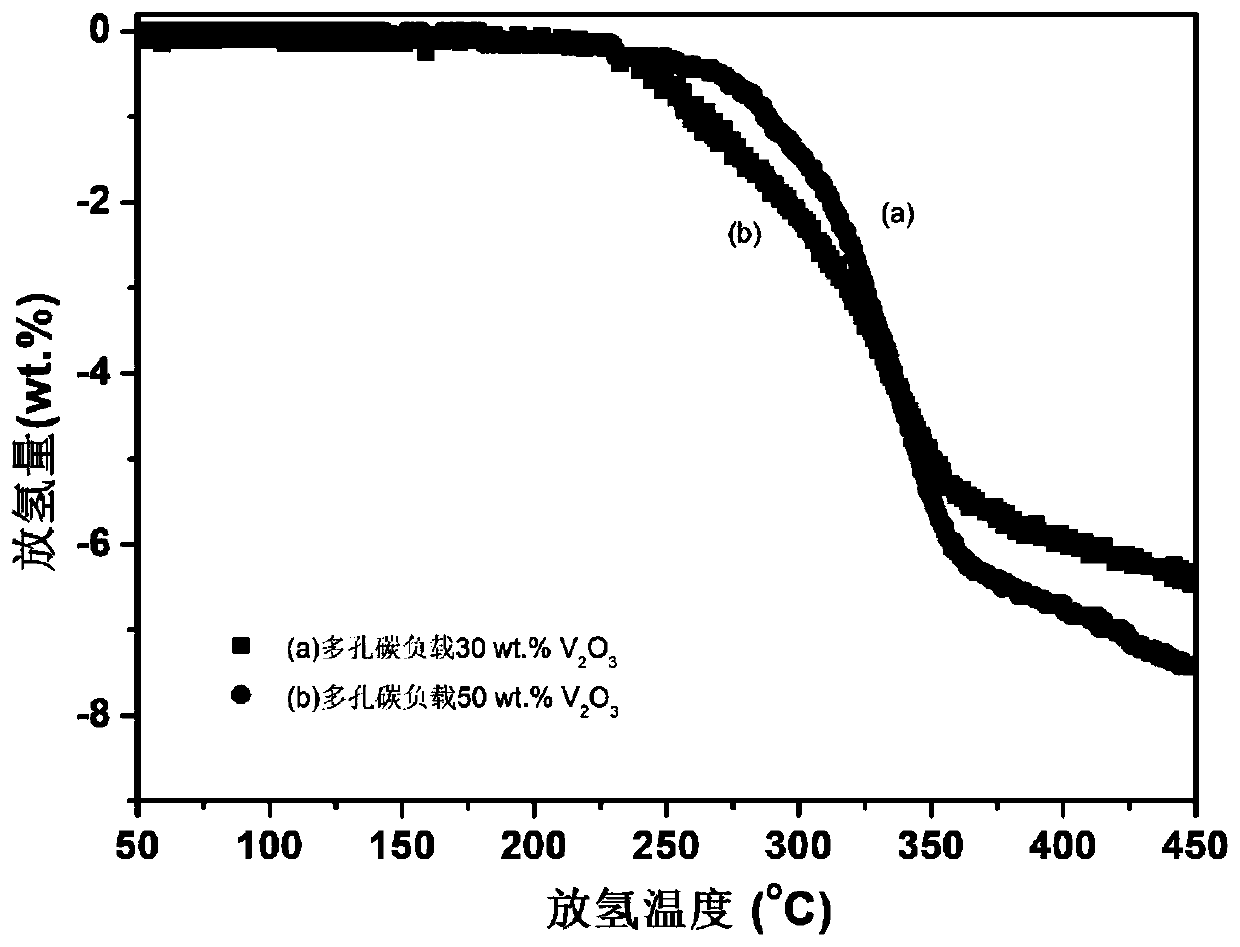

[0061] The preparation method and parameters of the porous carbon were the same as those in Example 1 where the addition of tetraethyl orthosilicate was 14 mL. Mix the obtained porous carbon with NH at mass ratios of 1:3 and 1:5 4 VO 3 Mix, add nitric acid to adjust the pH of the solution to 2, hydrolyze at 180°C for 24 hours, and then calcinate in an argon atmosphere at 500°C for 2 hours to obtain porous carbon loaded with 30wt.% and 50wt.% nano V 2 o 3 of composite materials.

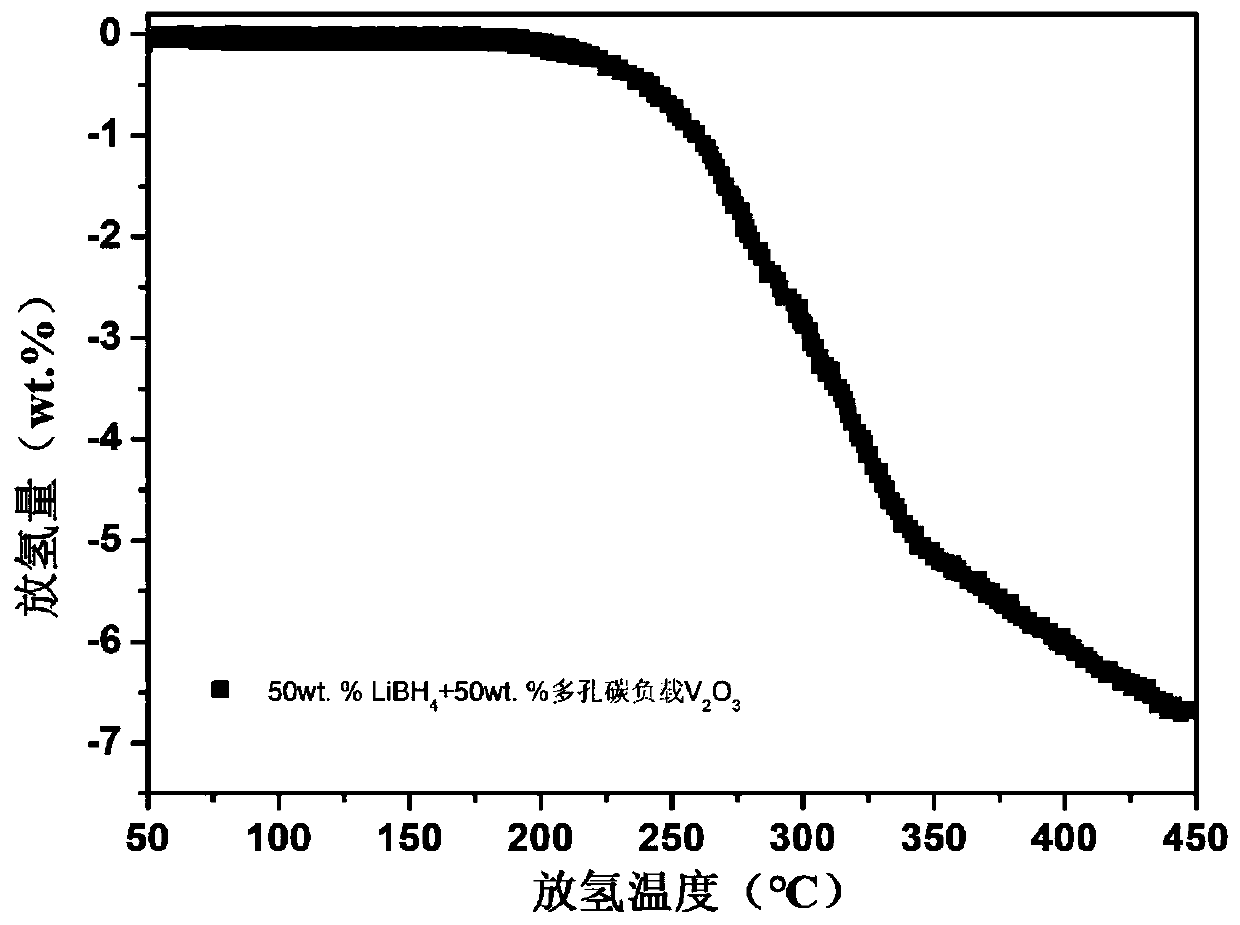

[0062] LiBH 4 Loadings of 30wt.% and 50wt.% nano V at a ratio of 60wt.% were obtained with 2 o 3 mixed with porous carbon, filled with hydrogen pressure at an initial pressure of 80bar, heated to 300°C, infiltrated for 30 minutes, cooled to room temperature, and formed LiBH 4 / 40wt% porous carbon loaded V 2 o 3 Composite hydrogen storage materials.

[0063] The hydrogen desorption performance of the material was tested by the volume hydrogen desorption method, and the initial vacuum degree wa...

Embodiment 3

[0065] The preparation of porous carbon with one-dimensional morphology is the same as that in Example 2. Mixing biphasic porous carbon and NH at a mass ratio of 1:4 4 VO 3 , adding nitric acid to adjust the pH of the solution to 2, and hydrolyzing at 180° C. for 24 hours. Then calcined at 500°C for 2 hours in an argon atmosphere to obtain a one-dimensional porous carbon-loaded 40wt.% nanometer V 2 o 3 composite material.

[0066] LiBH 4 With the ratio of 50wt.% and the obtained porous carbon supported nano V 2 o 3 Mixed, filled with hydrogen pressure at an initial pressure of 80bar, heated to 300°C for 30 minutes at a rate of 3°C / min and infiltrated for 30 minutes, and cooled to room temperature to obtain a composite hydrogen storage material.

[0067] The hydrogen desorption performance of the material was tested by the volume hydrogen desorption method, and the initial vacuum degree was 1×10 -3 Under the condition of Torr, hydrogen is released, heated to 450°C at a ...

Embodiment 4

[0069] One-dimensional porous carbon-supported nano V 2 o 3 The preparation of the composite material is the same as in Example 2. LiBH 4 With the ratio of 60wt.% and the obtained porous carbon supported nano V 2 o 3 Mixed, filled with hydrogen pressure at an initial pressure of 80 bar, heated to 300°C for infiltration for 30 minutes, and cooled to room temperature to obtain a composite hydrogen storage material. Figure 4 It is the X-ray diffraction pattern of the material, it can be seen from the figure that V 2 o 3 Sharp diffraction peaks, proving that V in porous carbon with one-dimensional morphology 2 o 3 The presence. One-dimensional porous carbon-supported nano V 2 o 3 N 2 (77K) adsorption-desorption curve and pore size distribution Figure 5 shown, which has a 2050cm 2 / g of the specific surface area and 1 ~ 5nm-based pore size. from Image 6 Shown (a) SEM morphology and (b) TEM morphology (c), and the SEM morphology of the material after five hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com