A kind of oxide solid electrolyte sheet and its preparation method and application

A solid electrolyte and oxide technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of defects in solid electrolyte sheets, through holes, affecting the performance of ultra-thin solid electrolytes, and improve the gas barrier. Sealing effect, large area span, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

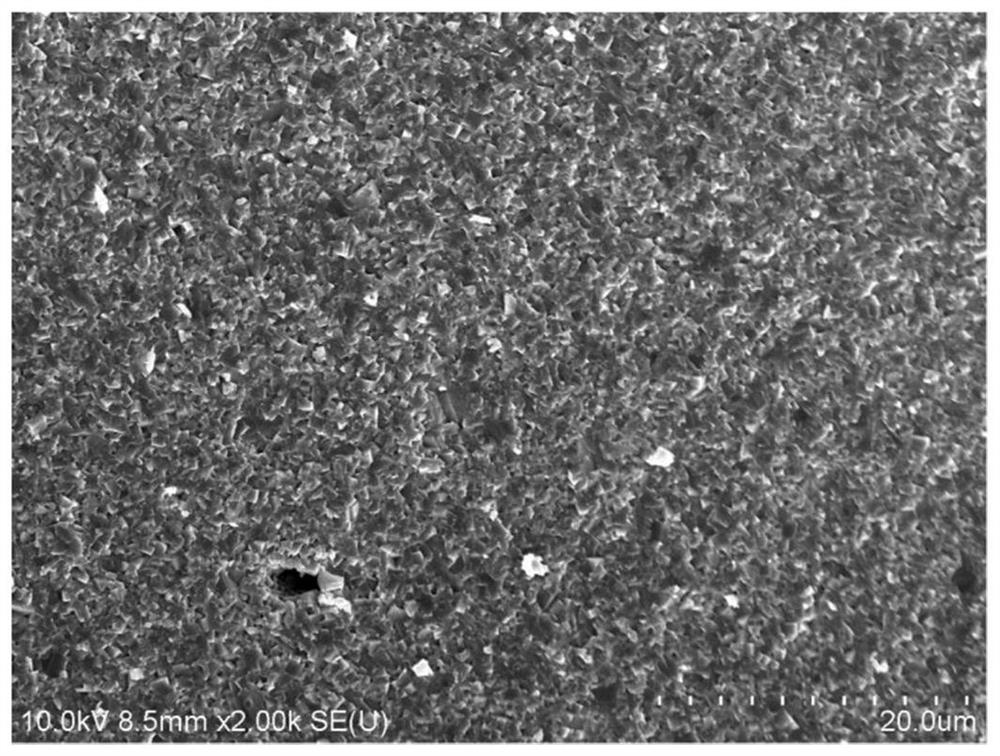

[0054] The present embodiment relates to a solid oxide electrolyte NASICON type LAGP (Li 1.5 Al 0.5 GE 1.5 (Po 4 ) 3 ) Sheet preparation, comprising the steps of:

[0055] 1) dispersion: 10g D50 is taken of the NASICON 500nm LAGP solid oxide electrolyte into a ball mill jar, followed by addition of a certain amount of the solvent (in this embodiment is a volume ratio of 1: 1 ethanol and xylene), addition of a dispersant, is added 80g zirconium ball, ball milled for 5 hours.

[0056] 2) Pulp: Take a certain amount of volume ratio of 1: 1 ethanol and xylene was poured into the cup glue, a plasticizer is added, then 1g of polyvinyl butyral (the PVB), carried out using a homogenizer glue. Open ball mill pot Step 1) was added to the prepared glue, milling continued 20h.

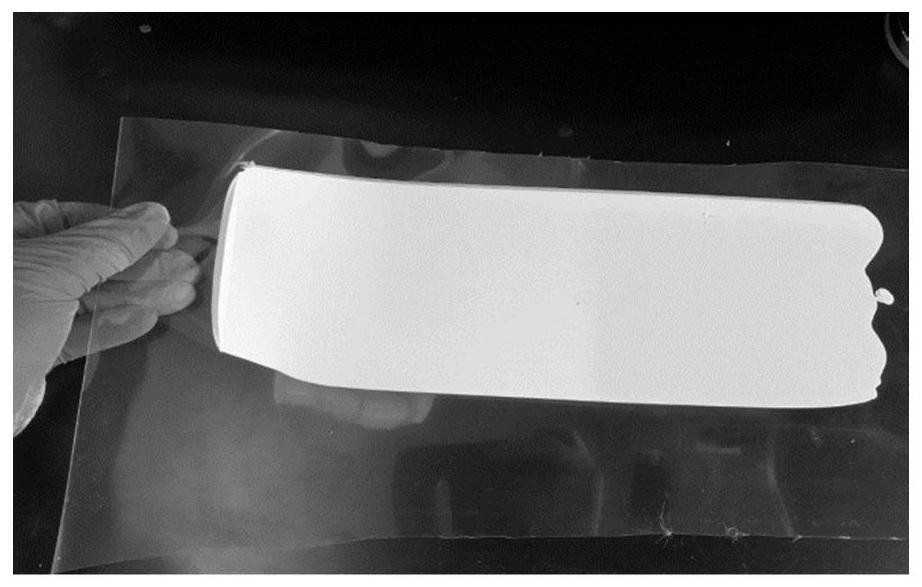

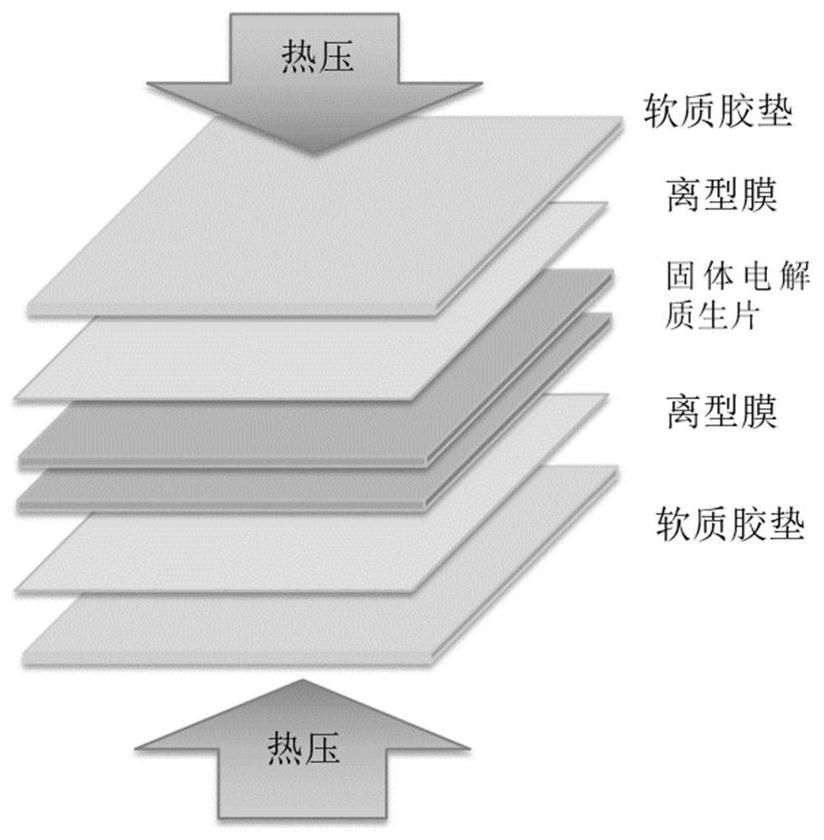

[0057] 3) Coating: Take a ball mill jar slurry is coated on a substrate, the coating having a thickness of 100 m, the solid electrolyte membrane will be completed together with the coated substrate to stand at ambient...

Embodiment 2

[0067] The present embodiment relates to a solid oxide electrolyte NASICON type LATP (Li 1.4 Al 0.4 Ti 1.6 (Po 4 ) 3 ) Sheet preparation, comprising the steps of:

[0068] 1) dispersion: Take 10g D50 of 300nm of the NASICON solid oxide electrolyte LATP into a ball mill jar, followed by addition of a certain amount of solvent, dispersant, was added 60g of zirconium balls, ball mill for 5 hours.

[0069] 2) Pulp: take a certain amount of the solvent system poured into plastic cups, a plasticizer was added, then 1g of polyvinyl alcohol (PVA), using a homogenizer for glue. Mill pot opening step 1), the prepared glue was added, ball milling continued for 16 h;

[0070] 3) Coating: Take a ball mill jar slurry is coated on a substrate, the coating having a thickness of 300 m, the solid electrolyte membrane will be completed together with the coated substrate to stand at ambient temperature drying solvent, and dried into a solid electrolyte green sheet, and dried 10h time hours, to obtain...

Embodiment 3

[0079] The present embodiment relates to a solid oxide electrolyte type Garnet LLZO (Li 7 La 3 Zr 2 O 12 ) Sheet preparation, comprising the steps of:

[0080] 1) dispersion: Take 10g D50 is 500nm Garnet type of solid oxide electrolyte LLZO (Li 7 La 3 Zr 2 O 12 ) Was placed in a ball mill jar, followed by adding a certain amount of solvent, dispersant, was added 90g of zirconium balls, milled for 4 hours.

[0081] 2) Pulp: take a certain amount of the solvent system poured into plastic cups, adding a plasticizer, then add 1.0g of polyvinyl butyral (the PVB), using a homogenizer for glue. Open ball mill pot Step 1) added and the prepared glue was added, continue milling 30h.

[0082] 3) Coating: Take a ball mill jar slurry is coated on a substrate, the coating having a thickness of 200 m, the solid electrolyte membrane will be completed together with the coated substrate to stand at ambient temperature drying solvent, and dried into a solid electrolyte green sheet, and dried 12h ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com