Cutting device accessory for special optical fiber, cutting device and optical fiber cutting method

A technology of cutting device and special optical fiber, applied in the field of cutting device and optical fiber cutting, can solve the problems of unguaranteed, smooth end face without tailing, difficult to ensure cutting effect, etc., and achieve the effect of small cutting angle and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

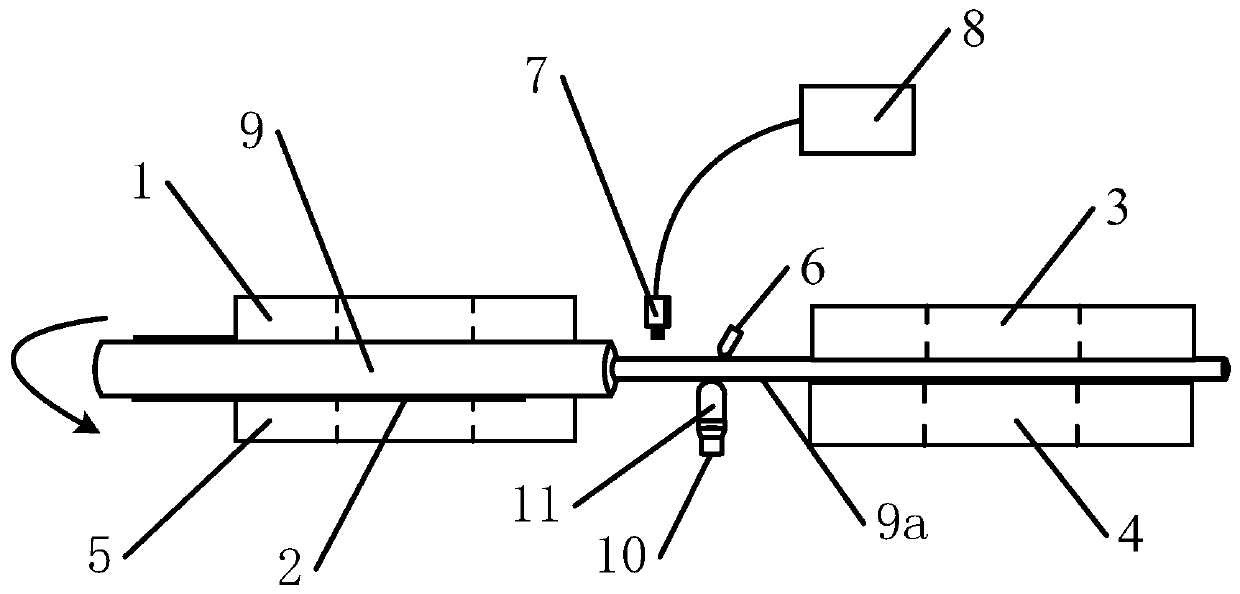

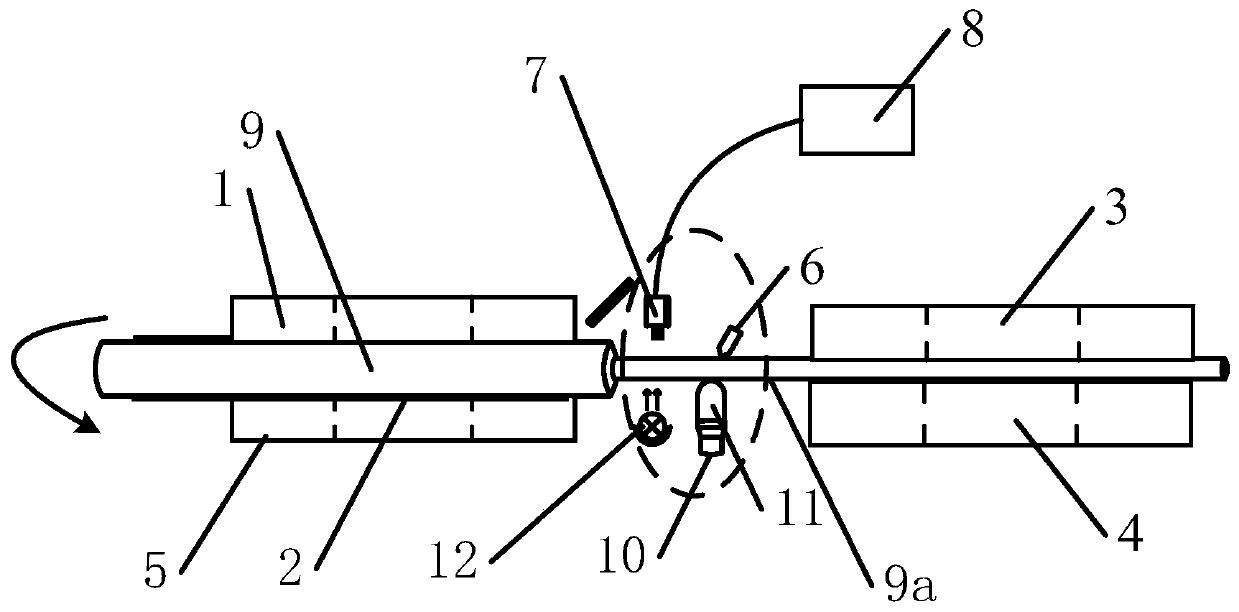

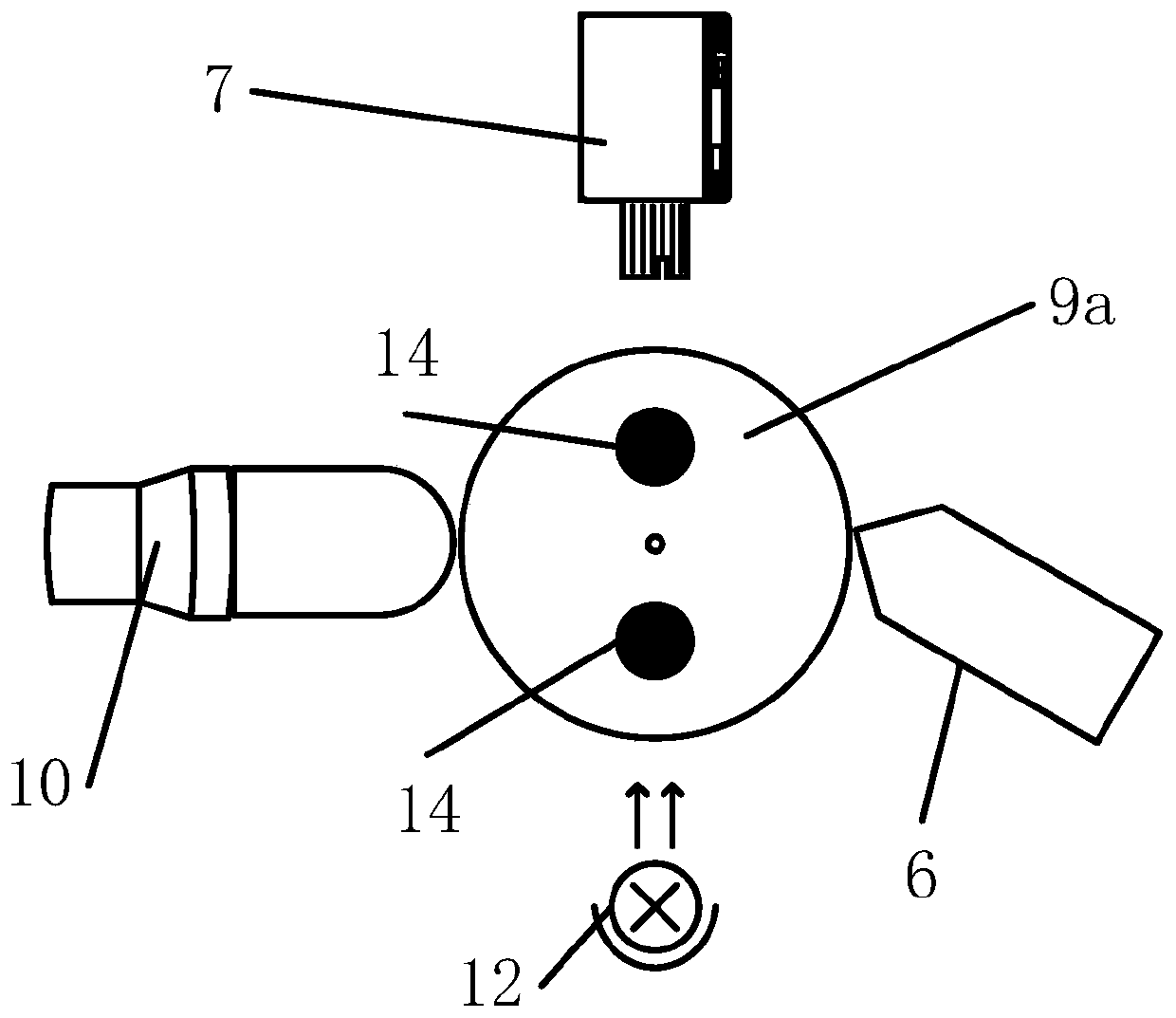

[0097] like figure 1 The cutting device in the shown optical fiber cutting equipment may include a left upper cover (the first upper cover 1), a clamp 2, a right upper cover (the second upper cover 3), and a right lower cover ( The second lower cover plate 4), the left lower cover plate (the second lower cover plate 5), cutting knife (knife 6), digital microscope (visual observation device 7), display 8, optical fiber to be cut (including Coated optical fiber segment 9 and optical fiber segment 9a) after stripping the coating layer, brake (piezoelectric actuator 10), top pressure block 11 (cylindrical top block) and the like. Among them, the jig can use Vytran's 3600 fusion splicer transfer jig, the diameter of the fiber groove of the jig matches the fiber to be cut, if the diameter of the fiber coating layer is 550 microns, the transfer jig should be 500 type; the cutting knife can be a diamond cutting blade; digital The microscope can use the super eye B11+L1000 lens; the o...

Embodiment 2

[0101] The microscope in the scheme can also adopt a visual optical microscope, which can directly observe the side of the optical fiber by visual observation, and is used to evaluate the rotation of the optical fiber to a specific position, and the same cutting effect as that in Example 1 can be obtained. Other configurations are the same as in Embodiment 1.

Embodiment 3

[0103] In the solution, the optical fiber is replaced with an octagonal optical fiber, and the optical fiber is rotated to a symmetrical position. Other configurations are the same as those in Embodiment 1, and the same cutting effect as in Embodiment 1 can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com