Two-hole pencil sharpener

A pencil sharpener and knife holder technology, which is applied in sharpening devices, printing, office supplies, etc., can solve the problems of poor cutting effect, wear and no change of the knife holder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings. It should be noted that the embodiments are only detailed descriptions of the technical solutions, preferred solutions and alternative solutions of the present invention, and their purpose is to make those skilled in the art better. It should not be considered as a limitation to the present invention.

[0036] The double-hole pencil sharpener of the present invention is mainly used for electric pencil sharpeners, and can also be used for manual pencil sharpeners. Its power mode can be selected according to actual needs and other factors such as manufacturing costs. The transmission mode usually adopts gears. transmission.

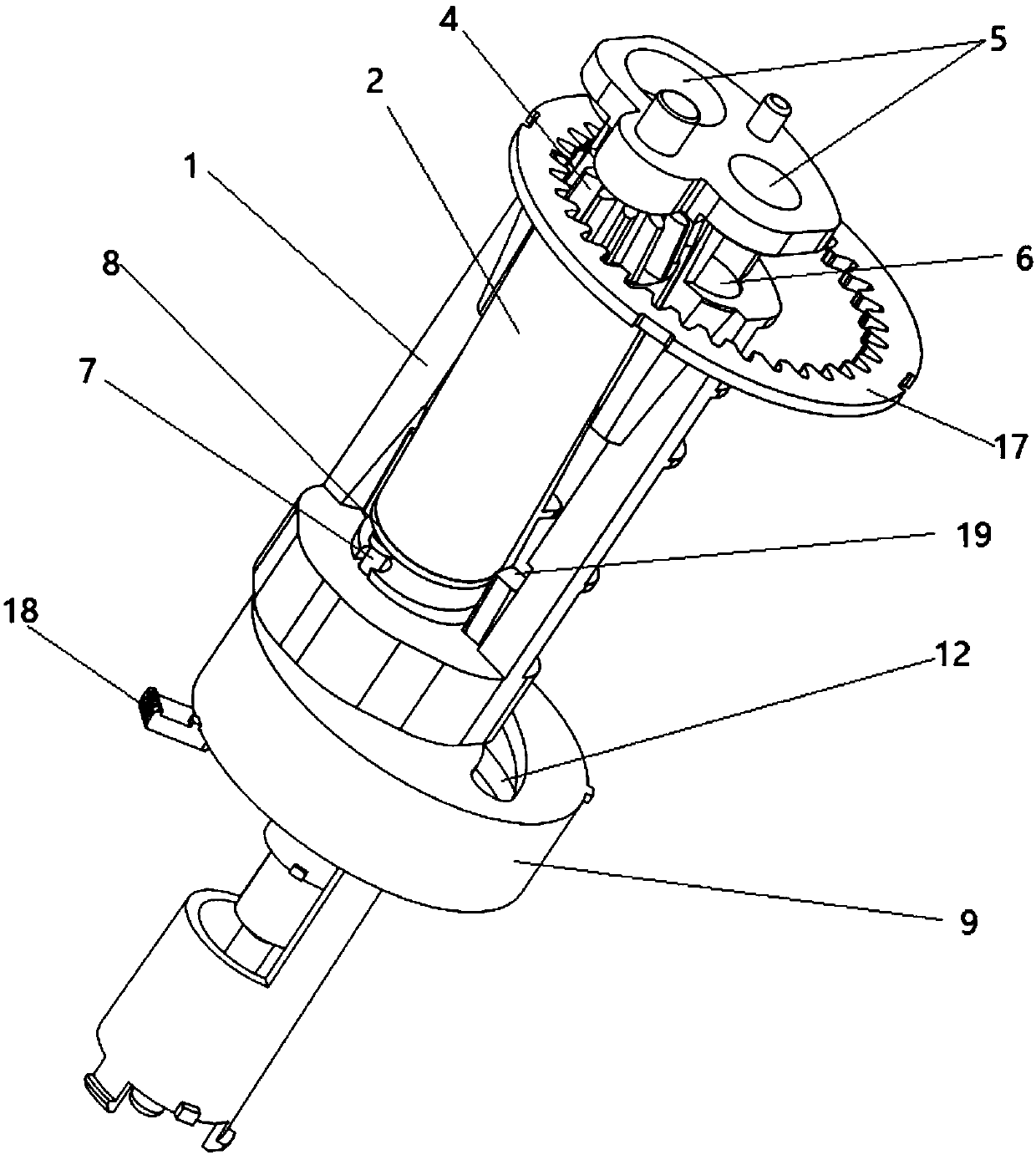

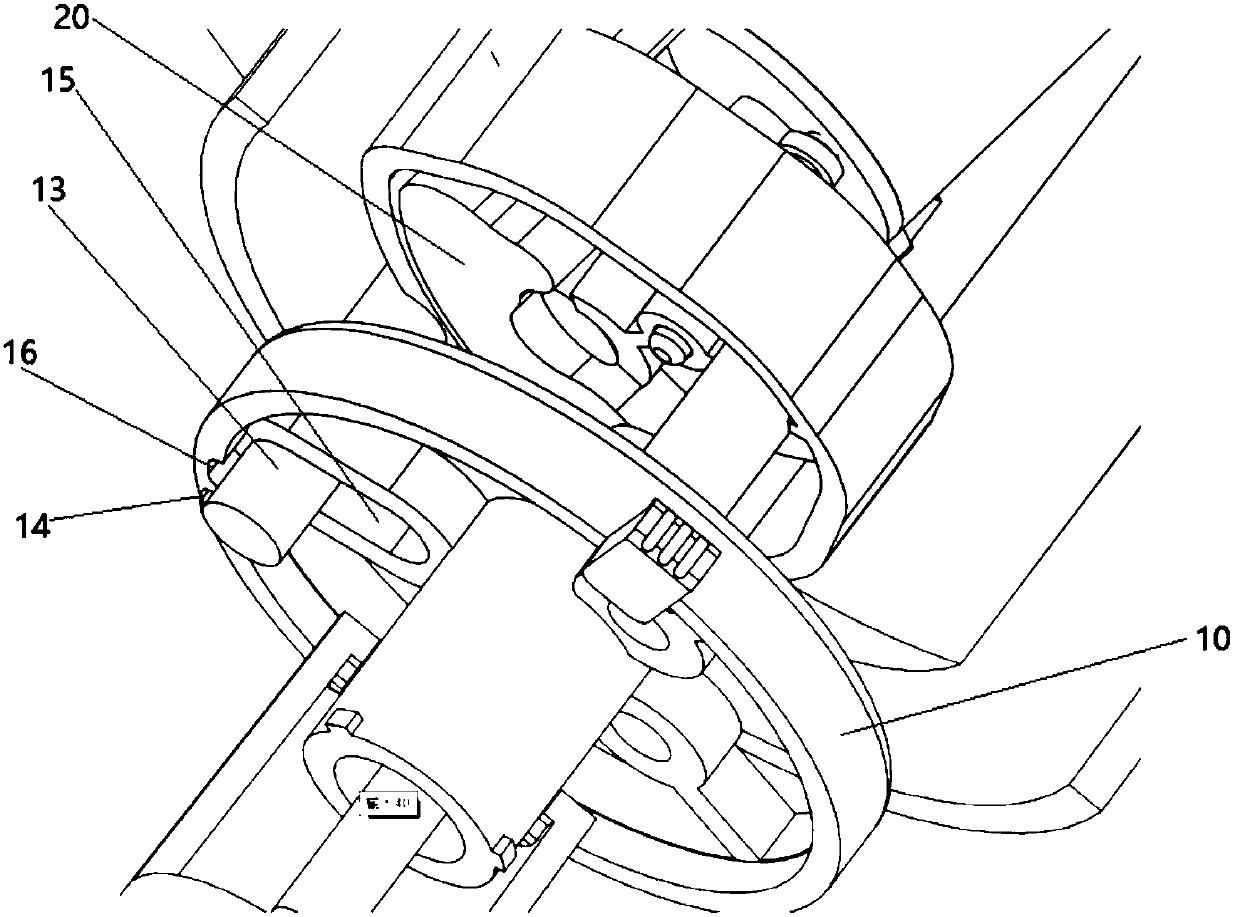

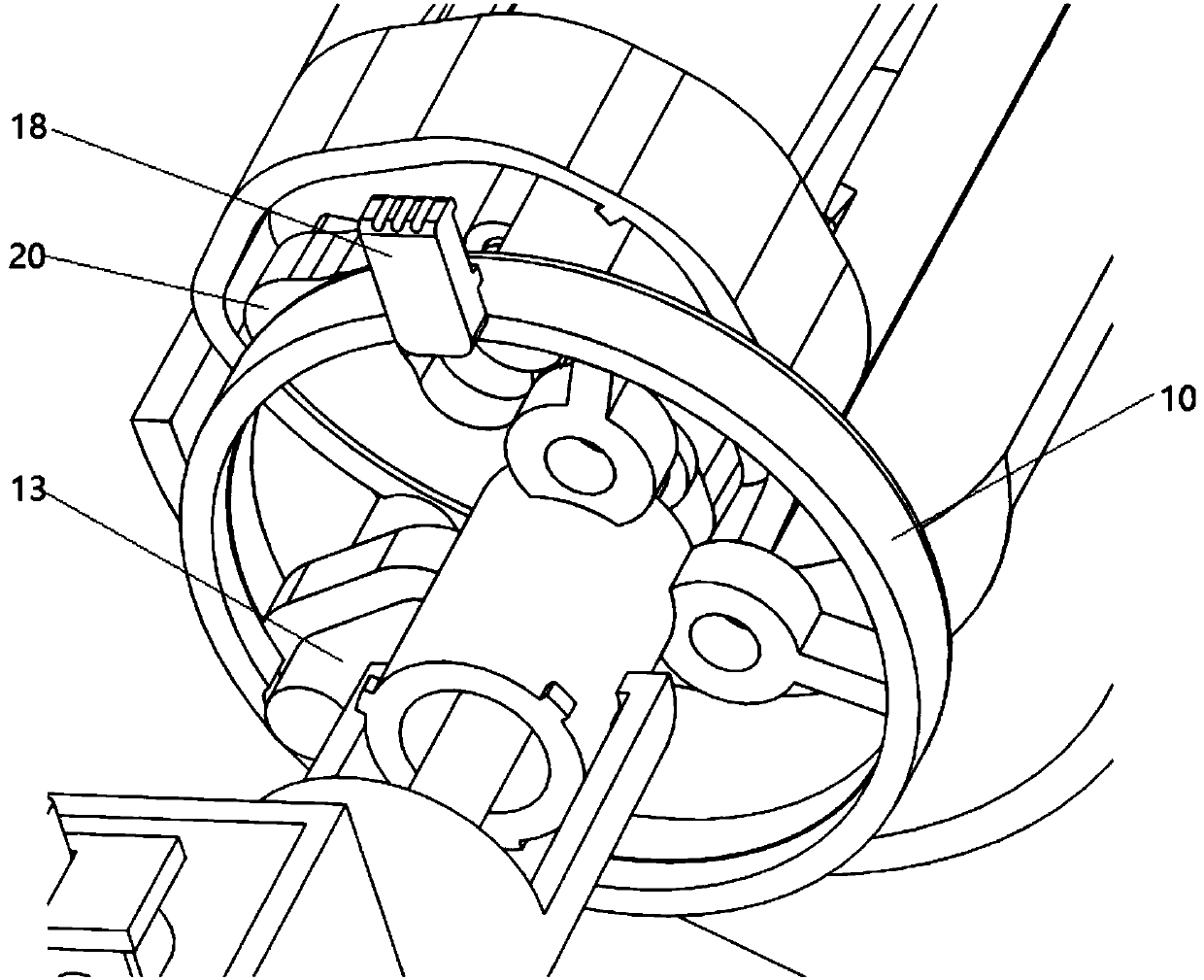

[0037] Such as figure 1 As shown, the double-hole pencil sharpener of the present invention includes a tool holder 1, a tool 2 is mounted on the tool holder 1, and the tool 2 is mounted on the tool holder 1 through a too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com