Press-cutting roller assembly

A component and roller technology, applied in the agricultural field, can solve the problems of high power consumption, large power consumption, poor rotary tillage effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

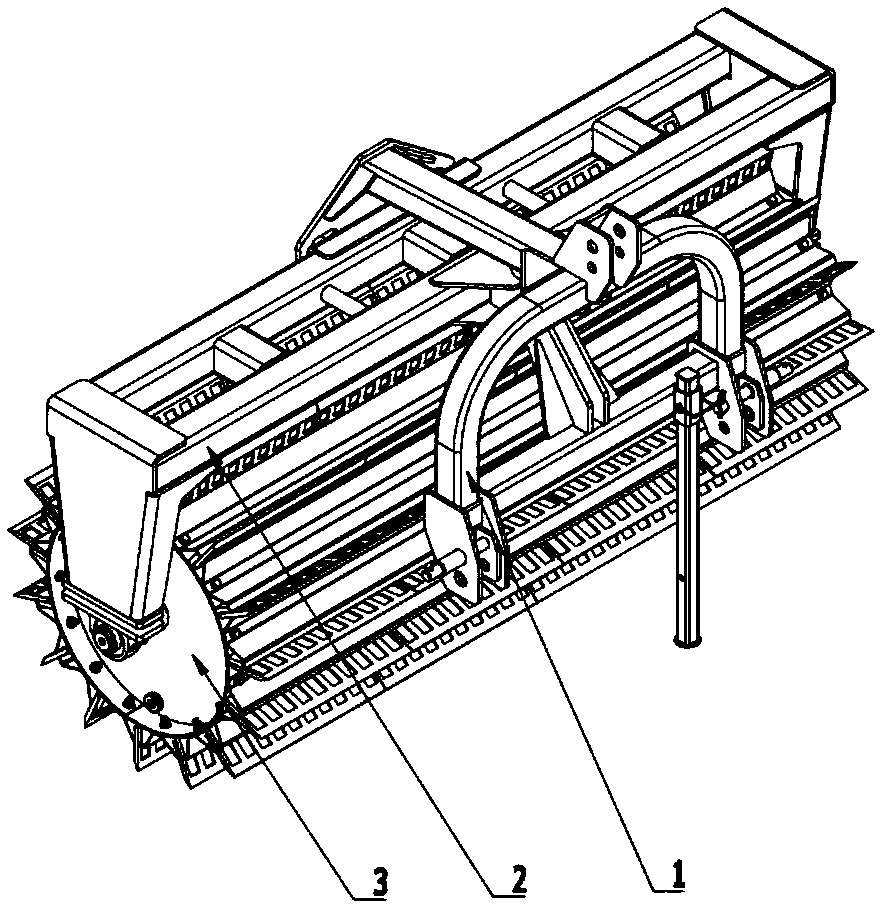

[0024] The pressure-cutting roller assembly of this embodiment is used as a roller-type pressure-cutting machine, taking into account the operation of overturning and pressing green manure in standard farmland and orchard forests. The basic structure of the roller-type pressure-cutting machine is as follows: figure 1 As shown, it includes a suspension assembly 1 for connecting with a tractor, a support assembly 2 connected with the suspension assembly 1 , and a press-cutting roller assembly 3 supported under the support assembly 2 .

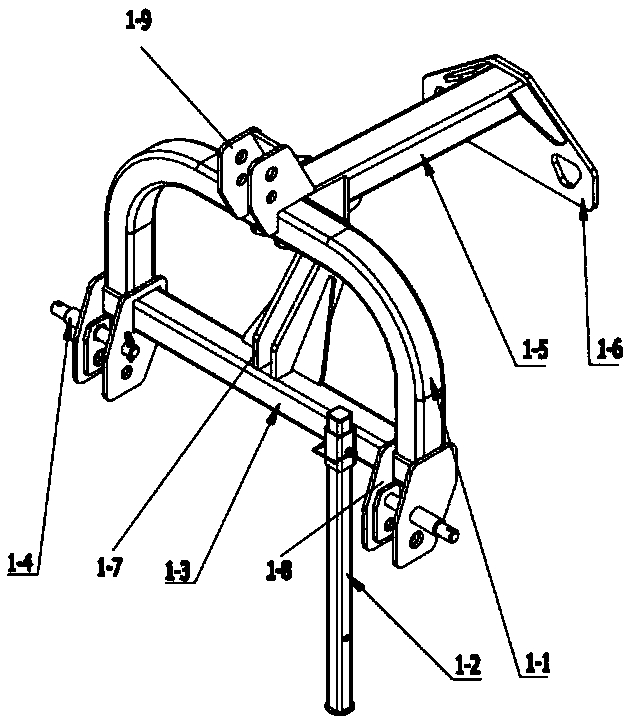

[0025] The structure of the suspension assembly 1 is as figure 2 As shown, it contains a door-shaped frame 1-1, the upper center of the door-shaped frame 1-1 is fixed with a longitudinal beam 1-5 extending forward, and the front end of the longitudinal beam 1-5 is fixedly connected with the vertical jack plate 1-5. 6. A transverse beam 1-3 is fixedly connected between the two lower ends of the portal beam 1-5, and the center of the transverse b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com