A steel cutting device for conveniently fixing special-shaped steel

A special-shaped steel and cutting device technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of low work efficiency, achieve the effects of improving work efficiency, simple operation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as figure 1 As shown, a steel cutting device for conveniently fixing special-shaped steel materials includes a bottom plate 1, a first bearing seat 2, a clamping mechanism 3, a moving mechanism 4 and a rotating mechanism 5, and the top of the bottom plate 1 is symmetrically provided with the first bearing seat 2, A clamping mechanism 3 is arranged in the middle of the first bearing seat 2 , a moving mechanism 4 is arranged on the top side of the bottom plate 1 , and a rotating mechanism 5 is connected to the middle part of the first bearing seat 2 and the clamping mechanism 3 .

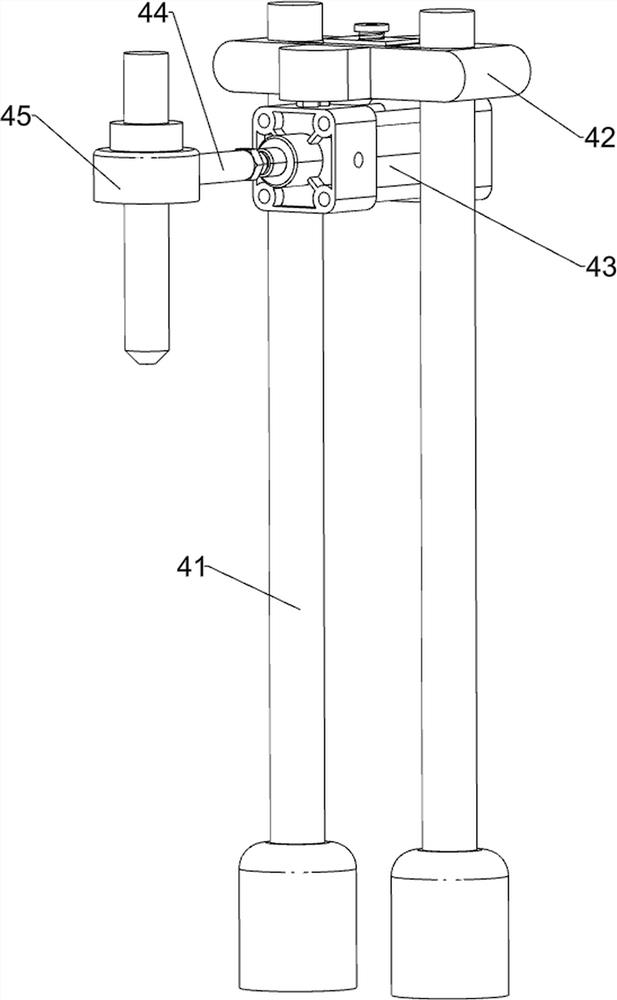

[0027] When the staff needs to fix the special-shaped steel for cutting, the special-shaped steel passes through the center of the two first bearing seats 2, and the pressing mechanism presses the two ends of the special-shaped steel respectively, and plasma nitrogen is used for cutting at one end of the special-shaped steel. For plasma melting cutting, the gas cutting torch 45 is driven b...

Embodiment 2

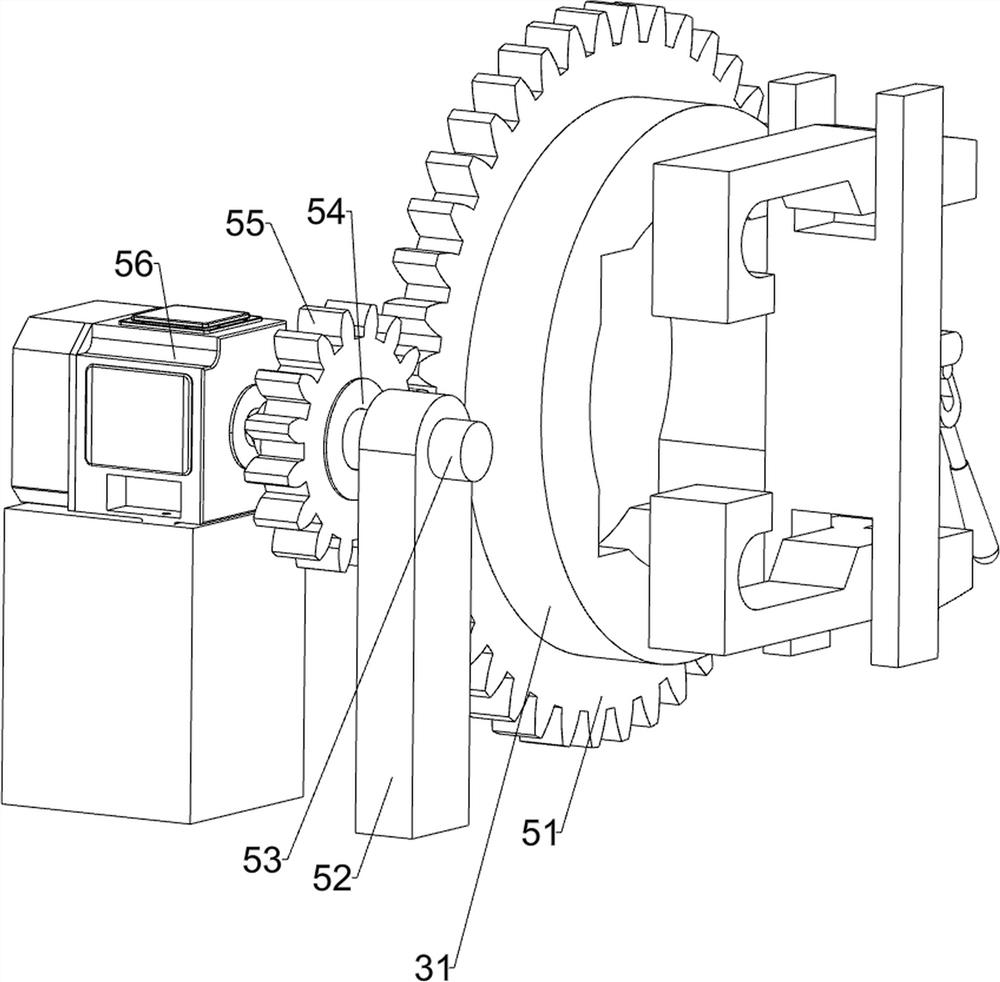

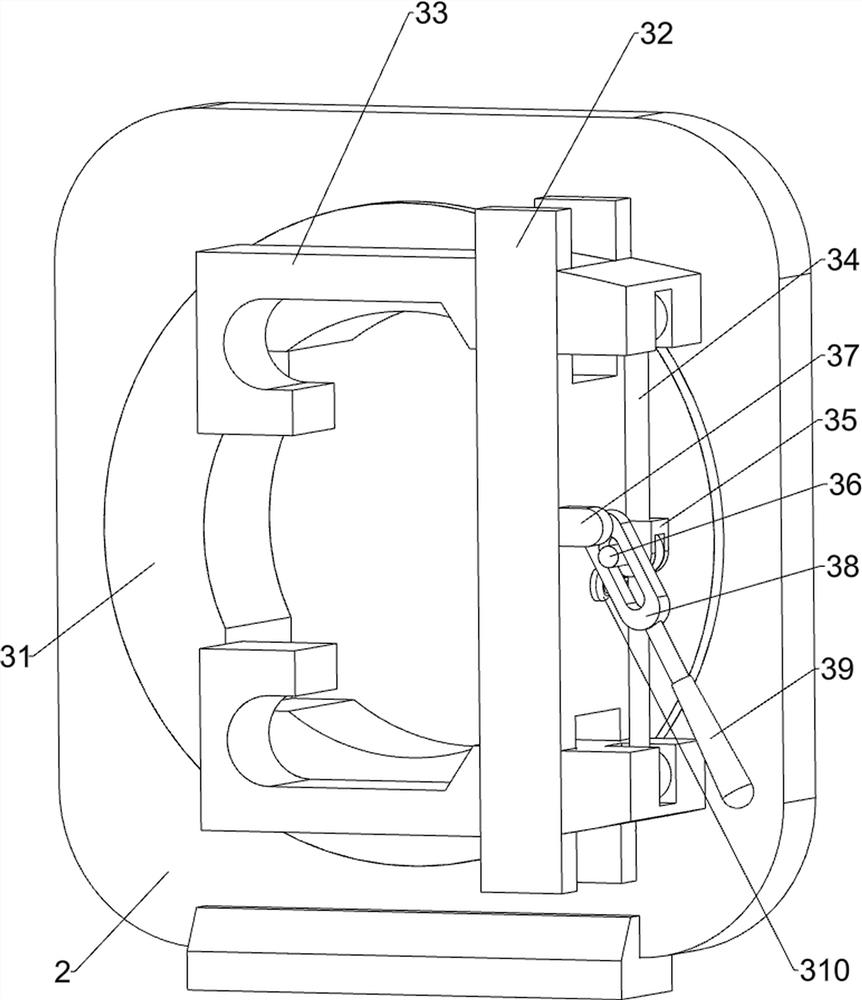

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a steel cutting device for conveniently fixing special-shaped steel materials includes a bottom plate 1, a first bearing seat 2, a clamping mechanism 3, a moving mechanism 4 and a rotating mechanism 5, and the top of the bottom plate 1 is symmetrically provided with the first bearing seat 2, One of the first bearing seats 2 is slidingly matched with the bottom plate 1, a clamping mechanism 3 is arranged in the middle of the first bearing seat 2, a moving mechanism 4 is arranged on the top side of the bottom plate 1, and the middle part of the first bearing seat 2 is in phase with the clamping mechanism 3. A rotating mechanism 5 is connected.

[0030] Clamping mechanism 3 comprises circular ring 31, H-shaped block 32, special-shaped clamping block 33, connecting rod 34, U-shaped block 35, latch 36, holder 37, chute plate 38, handle 39 and limit block 310, two A ring 31 is rotatably arranged in the middle...

Embodiment 3

[0035] Such as Figure 5 and Figure 6 As shown, on the basis of Embodiment 2, a steel cutting device for conveniently fixing special-shaped steel also includes a side plate 6, a guide rail 7, a nut guide sleeve 8, a screw mandrel 9, a one-way clutch 10, a turntable 11, Guide blocks 12 and rollers 13, a side plate 6 is provided at the edge of the bottom plate 1 close to the first rotating shaft 53, and two guide rails 7 are symmetrically arranged on the side of the side plate 6 near the first rotating shaft 53, and the two guide rails 7 are slidingly arranged There is a nut guide sleeve 8, and the nut guide sleeve 8 is fixedly connected with the first bearing seat 2. The nut guide sleeve 8 is slidingly provided with a screw 9 in the middle of one side close to the guide rail 7. The first rotating shaft 53 and the screw rod 9 pass through the one-way clutch 10 Transmission connection, the end of the screw rod 9 away from the one-way clutch 10 is provided with a turntable 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com