Double-wire cutting device for amorphous motor iron core

A wire cutting and iron core technology, used in attachments, electrode manufacturing, electric processing equipment, etc., can solve problems such as low processing efficiency, improve efficiency, improve processing accuracy, and achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

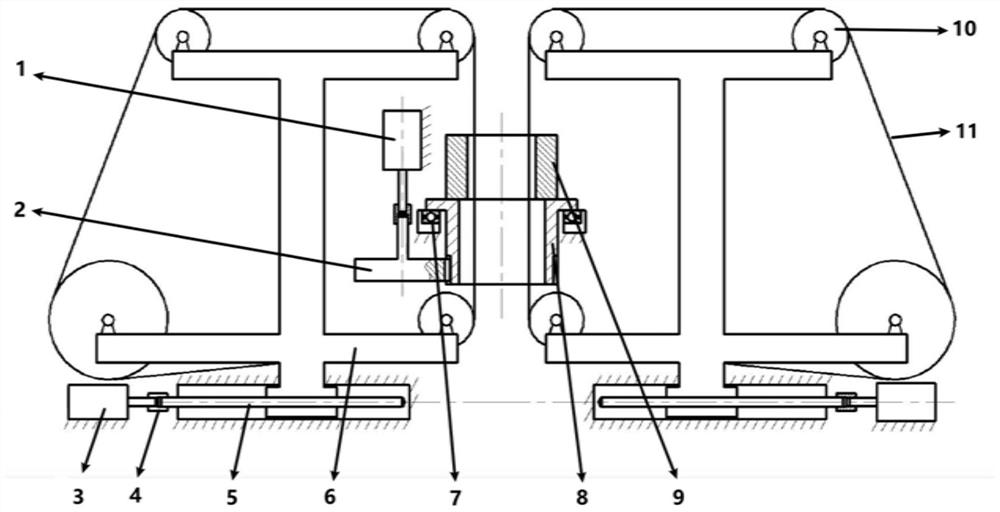

[0049] The double-wire wire EDM structure of the motor core is mainly composed of a rotating clamping table 8, two sets of wire cutting wire feeding components and two sets of sliding tables. on stage. The iron core of the motor is an even-numbered slot, which is a symmetrical structure, and the iron core of the motor is generally a cylindrical component. In this application, the blank is clamped on the rotary clamping table 8, so that the synchronously reciprocating wire-cut wire feeding part 6 processes the inner wall or the outer wall at the same time, thereby reducing the processing time by half. The rotary clamping table 8 is fixed in the inner hole of a large thrust ball bearing 7, and the rotary clamping table 8 drives itself to rotate through the external belt or gear 2, thereby driving the workpiece clamped on the rotary clamping table 8 9 for rotating motion. The rotary clamping table 8 is a hollow flange structure, and the cutting lines of the two sets of wire tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com