Three-negative elastic wave metamaterial with wide forbidden band

A metamaterial, elastic wave technology, applied in the functional characteristics of springs/shock absorbers, spring assemblies composed of several springs, springs, etc., can solve the problem of less research and development of practical functional devices, and has not yet entered the stage of large-scale application, etc. problem, to achieve the effect of increasing the frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

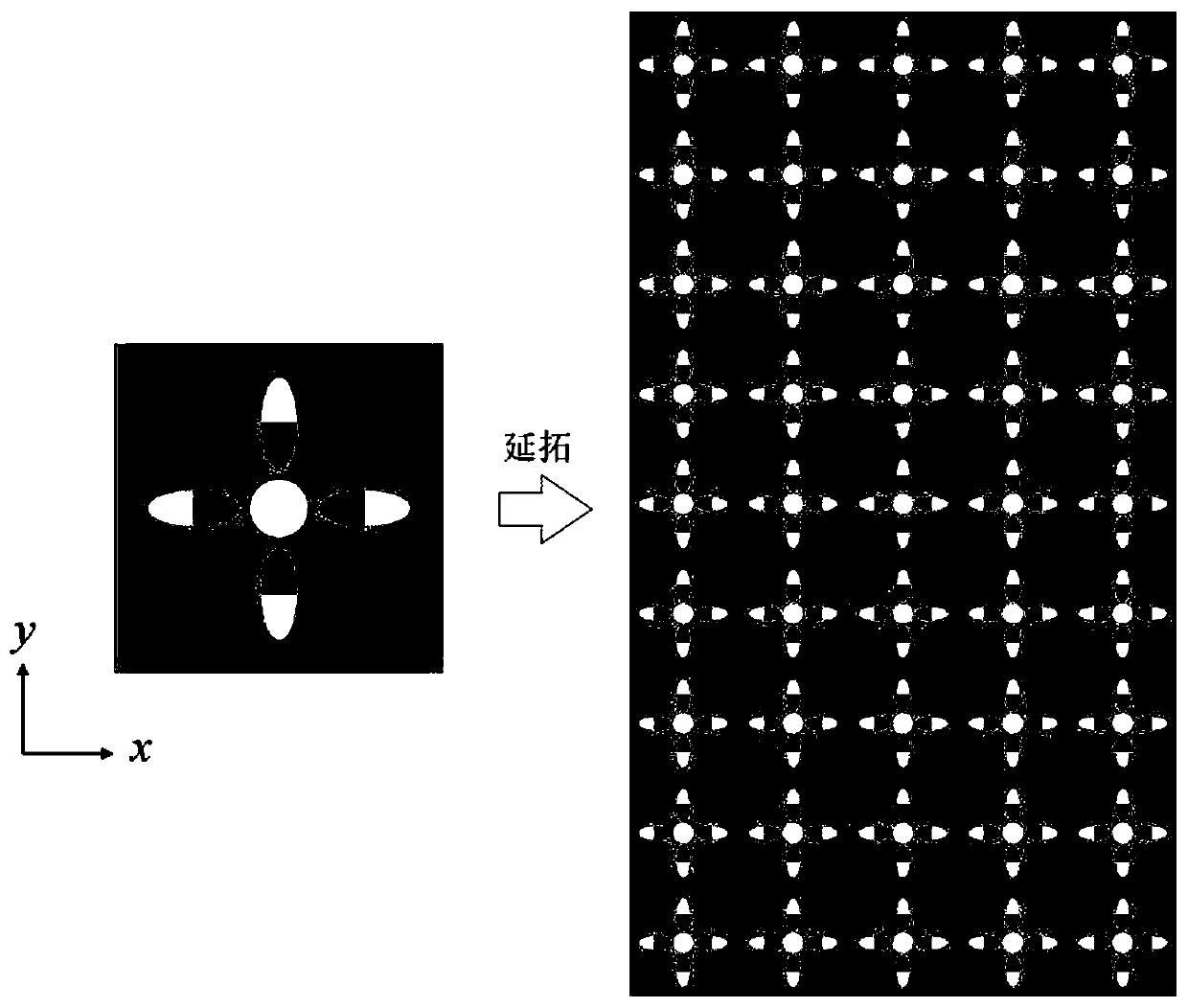

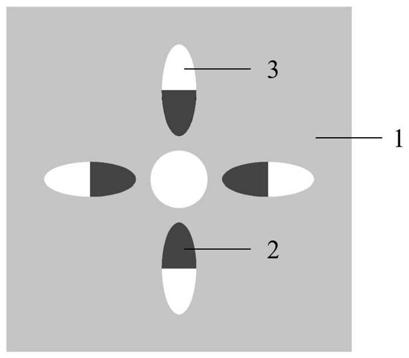

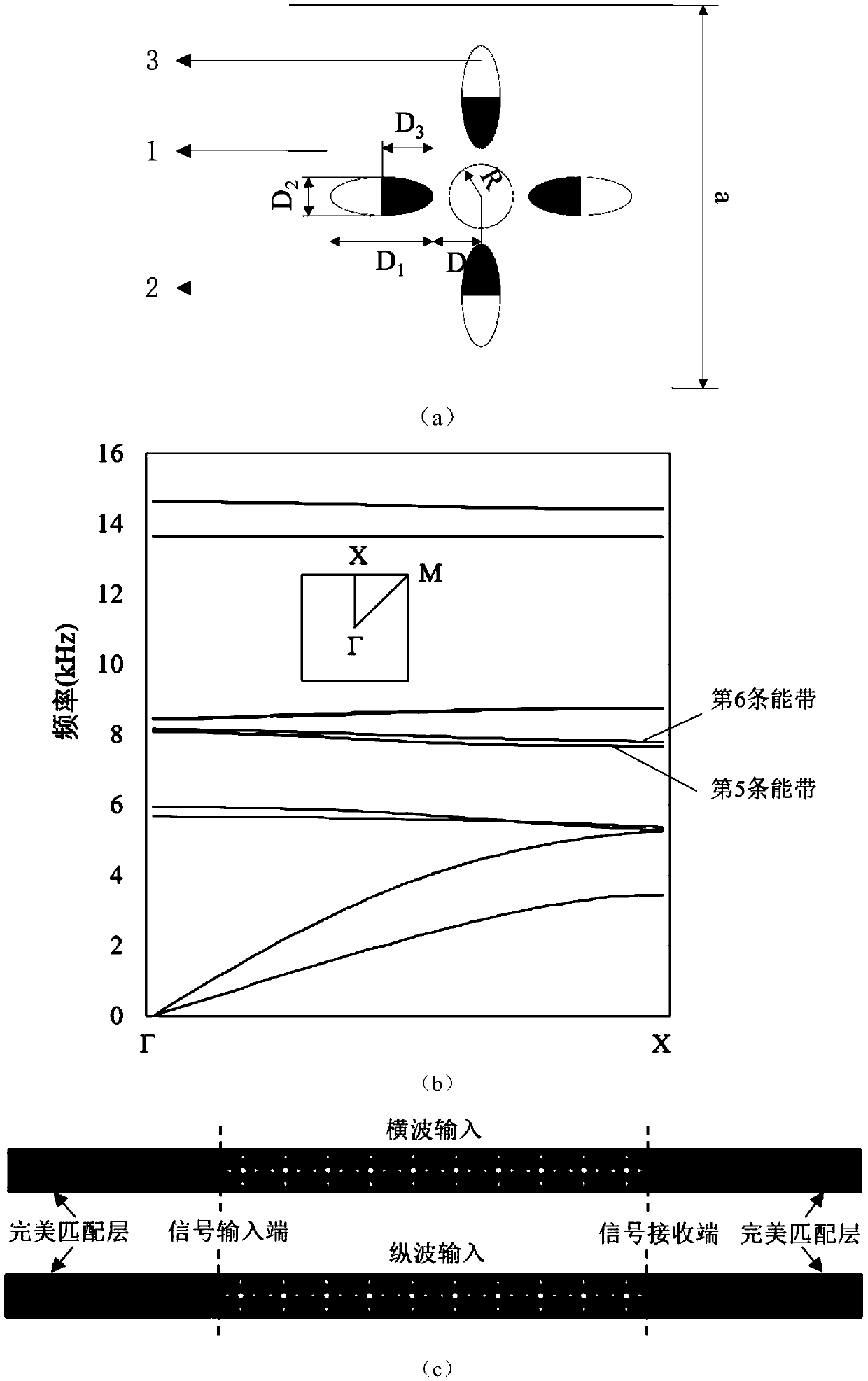

[0025] Implementation Case 1: If image 3 as shown, image 3 (a) is a design diagram of a triple negative elastic wave metamaterial unit cell with a wide band gap, in which a=6mm, R=1mm, D 1 = 1.6mm, D 2 = 0.6mm, D 3 = 0.8mm, D 4 = 0.3mm. image 3 (b) is the energy band structure diagram of the unit cell, and the three negative parameters appear in the overlapping parts of the fifth and sixth negative energy bands (it can be proved by observing the displacement eigenfields of these two energy bands). The second forbidden band width of the unit cell is about 4.5kHz, which is higher than the similar forbidden band width. image 3 (c) is a three-negative elastic wave metamaterial belt composed of ten such unit cells. The transmission curve calculated according to this model is as follows image 3 As shown in (d), the transmission rate of longitudinal wave and shear wave is relatively high in the overlapping part of the fifth and sixth energy bands, while the transmission ra...

Embodiment example 2

[0026] Implementation Case 2: If Figure 4 as shown, Figure 4 (a) is a functionally graded material that can bend the elastic wave path and propagate in an arc. It can be seen that the first layer is composed of negative refraction metamaterials. Bundle figure 2 The unit cell in Figure 4 The first layer of functionally graded material in (a), forming a new functionally graded material such as Figure 4 (b) shown. This functionally graded material composed of three negative elastic wave metamaterials has a forbidden band, which can prevent the propagation of elastic waves within the forbidden band frequency, and can propagate elastic waves at certain frequencies that cannot be prevented by the forbidden band. Path, to avoid it from affecting the target that needs to be protected, so the functionally graded material can use its forbidden band and passband to jointly isolate vibration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com