Method for preparing steel-making furnace burden from blast furnace gas dust zinc-extraction kiln slag

A blast furnace gas ash and steelmaking furnace technology, applied in the field of metallurgical solid waste resource recycling, to achieve the effects of wide selection range, environmental protection, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

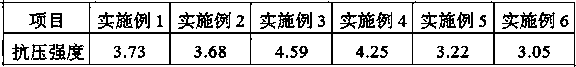

Examples

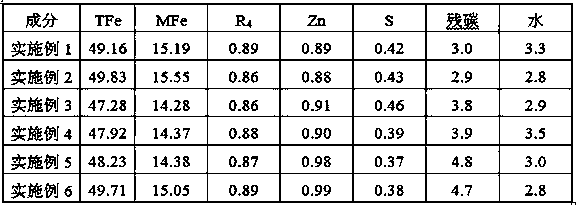

Embodiment 1

[0036] The method for preparing steelmaking charge by utilizing blast furnace gas ash to extract zinc kiln slag comprises the following steps:

[0037] a. The hot slag of the rotary kiln rotary kiln for zinc extraction from blast furnace gas ash falls from the kiln head, flushes the fire with water for slag flushing, granulates, and then sinks into the bottom of the slag pool; during the slag flushing process, the temperature of the water is 55°C and the water pressure is 1.5kg / cm 2 , the amount of water is 10 times the amount of slag;

[0038] b. The granulated kiln slag cooled at the bottom of the slag pool is taken out with a chain scraper conveyor, dehydrated and then dried naturally to obtain granulated rotary kiln slag; TFe: 52%; MFe: 16%; R 4 : 0.8; K: 0.19%; Na: 0.31%; Zn: 0.93%; carbon residue 3%; water content 4%;

[0039] c. Weigh the granulated rotary kiln slag, mineral powder, and desulfurized gypsum according to the mass ratio of 400:16:2, and mix them evenly ...

Embodiment 2

[0044] The method for preparing steelmaking charge by utilizing blast furnace gas ash to extract zinc kiln slag comprises the following steps:

[0045] a. The hot slag of the rotary kiln rotary kiln for zinc extraction from blast furnace gas ash falls from the kiln head, flushes the fire with water for slag flushing, granulates, and then sinks into the bottom of the slag pool; during the slag flushing process, the temperature of the water is 55°C and the water pressure is 1.5kg / cm 2 , the amount of water is 10 times the amount of slag;

[0046] b. The granulated kiln slag cooled at the bottom of the slag pool is taken out with a chain scraper conveyor, dehydrated and then dried naturally to obtain granulated rotary kiln slag; TFe: 52%; MFe: 16%; R 4 : 0.8; K: 0.19%; Na: 0.31%; Zn: 0.93%; carbon residue 3%; water content 4%;

[0047] c. Weigh the granulated rotary kiln slag, slag, and desulfurized gypsum according to the mass ratio of 450:18:6, and mix them evenly with a f...

Embodiment 3

[0052] The method for preparing steelmaking charge by utilizing blast furnace gas ash to extract zinc kiln slag comprises the following steps:

[0053] a. The hot slag of the rotary kiln rotary kiln for zinc extraction from blast furnace gas ash falls from the kiln head, flushes the fire with slag flushing water pipe, turns off the fire, granulates, and then sinks into the bottom of the slag pool; during the slag flushing process, the temperature of the water is 55°C and the water pressure is 1.2kg / cm 2 , the amount of water is 8 times the amount of slag;

[0054] b. The granulated kiln slag cooled at the bottom of the slag pool is taken out with a chain scraper conveyor, dehydrated and then dried naturally to obtain granulated rotary kiln slag; the granularity of granulated rotary kiln slag is between 2.5mm and 5mm, and the main components are TFe: 50%; MFe: 15%; R 4 : 0.9; K: 0.21%; Na: 0.35%; Zn: 0.94%; residual carbon 4%; water content 5%;

[0055] c. Weigh the granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com