FeOCl-based lignocellulose pretreatment system and application thereof

A lignocellulose, pretreatment technology, applied in the direction of fermentation, etc., can solve the problem that FeOCl has no application yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] FeOCl used in the present invention is made through the following steps:

[0044] Put an appropriate amount of ferric chloride hexahydrate into a mortar, grind it thoroughly, and then transfer it to a crucible; cover the crucible, put it in a muffle furnace, and heat it at 220 °C for 60 min in an air atmosphere; take out the sample, and use Wash with water and acetone to remove unreacted ferric chloride to obtain purple-red FeOCl.

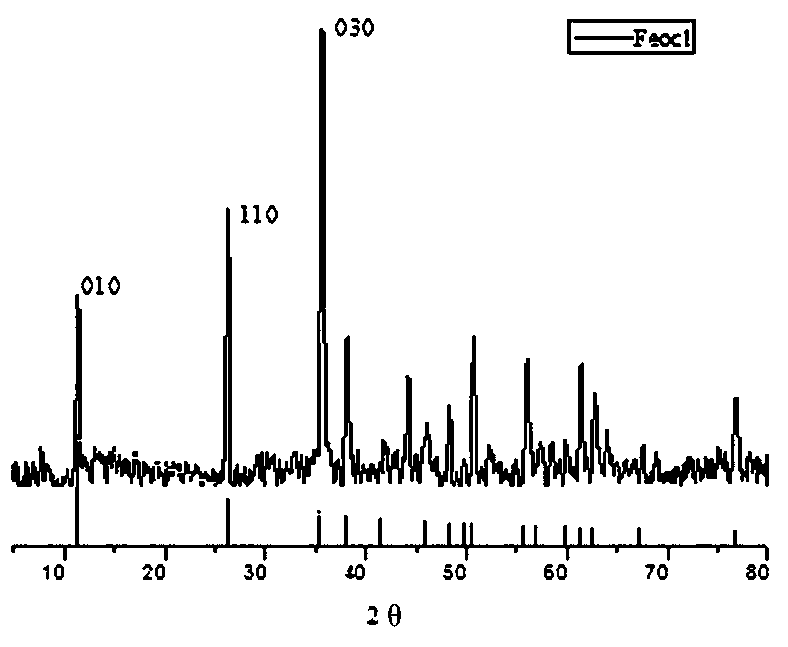

[0045] In order to verify the purity of the obtained FeOCl, it was characterized by X-ray diffraction, X-ray photoelectron spectroscopy and scanning electron microscopy (SEM);

[0046] figure 1 It is the XRD spectrum of the prepared FeOCl. It can be seen that the prepared sample of the present invention completely corresponds to the standard peak position of FeOCl, and the diffraction peak shape is sharp, indicating that the prepared FeOCl has a high purity and a complete crystal form;

[0047] figure 2 It is the XPS spectrum of FeOCl, i...

Embodiment 2

[0051] In order to investigate the pretreatment effect of the Fenton-like catalytic reaction system participated in by FeOCl on lignocellulosic raw materials, the present invention uses FeOCl and hydrogen peroxide to form a Fenton-like reaction system to pretreat corn stalks, and then investigates the pretreatment of corn stalks The degradation effect of medium cellulose, the specific test process is as follows:

[0052] 1. Test method

[0053] (1) Fenton-like pretreatment

[0054] Weigh 5g of crushed corn stalks, add it to 100mL pretreatment system, and after a period of treatment at room temperature, wash and dry the sample for subsequent enzymatic hydrolysis;

[0055] (2) Enzymatic treatment

[0056] Weigh 0.5 g of the treated corn stalk sample into a 50 mL Erlenmeyer flask, add 20 mL of 0.05 M citric acid-sodium citrate buffer, the pH of the buffer is 4.8; Add a certain amount of cellulose compound enzyme, stir well and put it in a shaker at 50°C and 180 r / min for 48 h;...

Embodiment 3

[0082]The test results of Example 2 show that the Fenton-like pretreatment system composed of FeOCl can improve the enzymatic hydrolysis efficiency of cellulose in corn stalks within the pH range of 3-8, that is, the Fenton-like pretreatment system can promote the enzymatic hydrolysis of corn stalks. Degradation of medium cellulose, effectively shorten the pretreatment time. However, in natural lignocellulosic raw materials, cellulose, hemicellulose and lignin exist in a certain covalent bond, and the degradation of cellulose will theoretically be accompanied by the degradation of lignin and hemicellulose; The effect of the above pretreatment system on the degradation and extraction of lignin in corn stalks was investigated. The specific test process is as follows:

[0083] 1. Test method

[0084] (1) Degreasing treatment

[0085] When corn stalks are used for lignin extraction, hydroalcoholic treatment is carried out first, the purpose is to remove the pigments and lipids o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com