Resveratrol-based bio-based carbon fiber composite material and preparation method thereof

A fiber composite material and a technology of resveratrol, which are applied in the field of bio-based carbon fiber composite materials based on resveratrol and their preparation, can solve the problems of long curing cycle and high curing temperature of carbon fiber composite materials, and achieve shortening curing time, The effect of lowering curing temperature and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

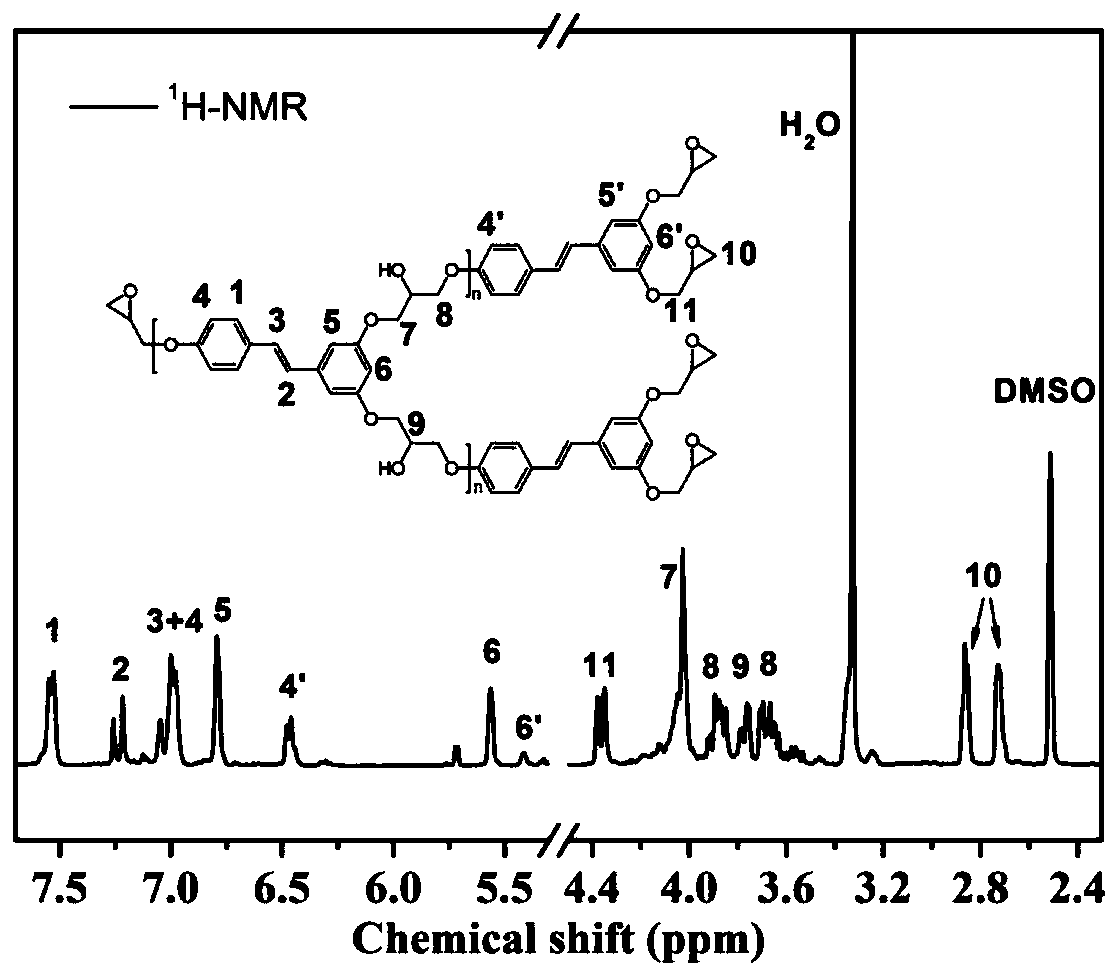

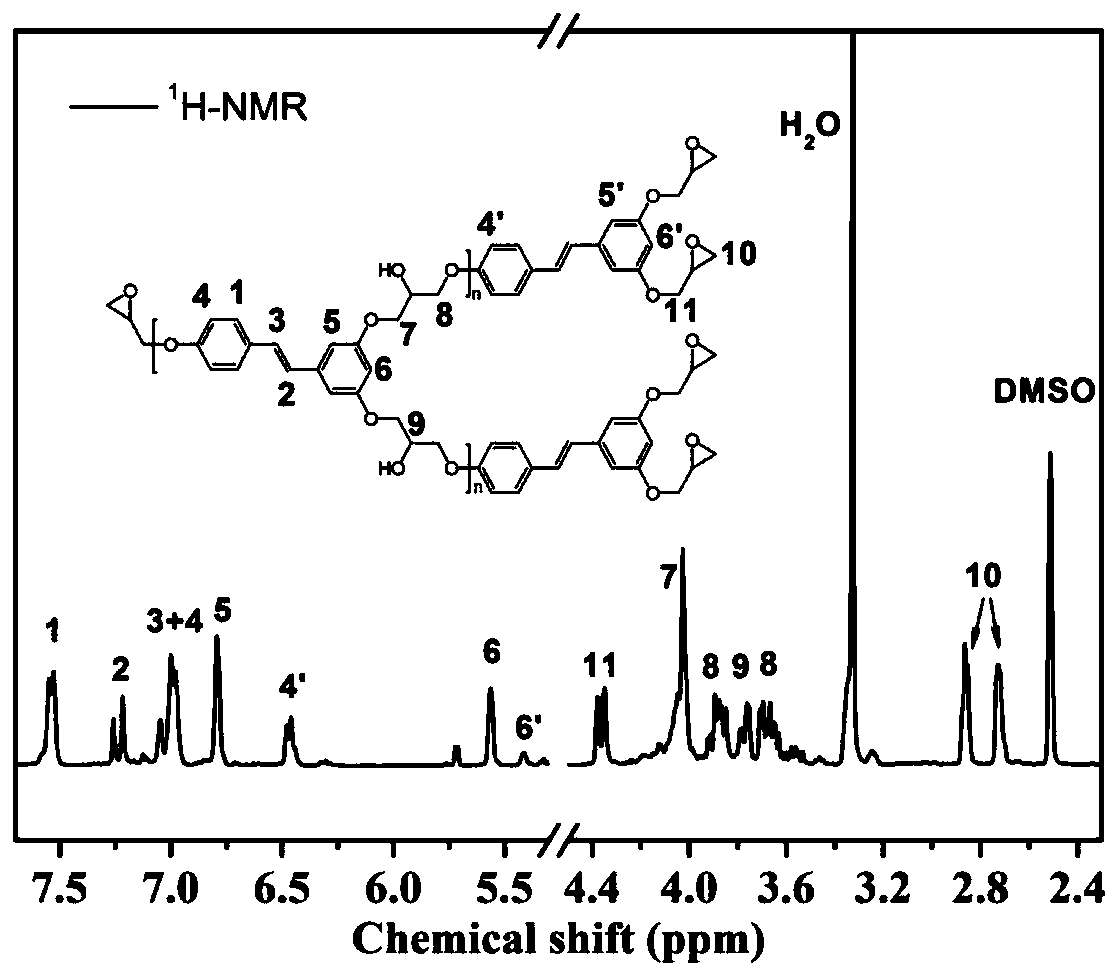

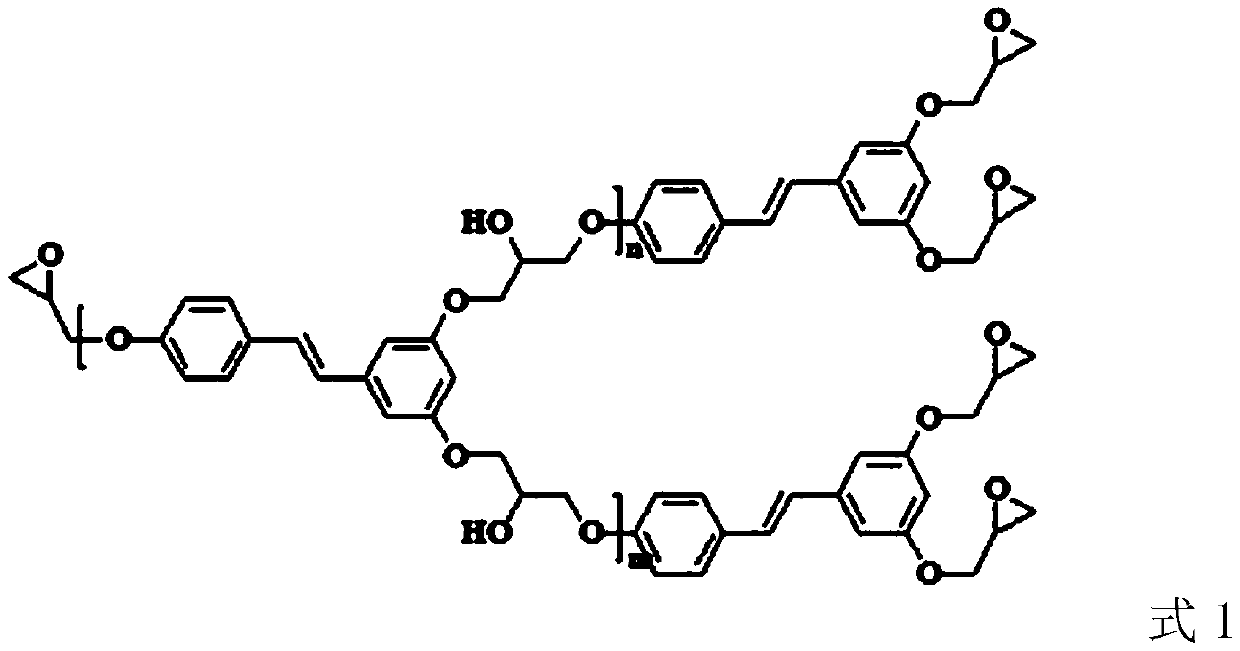

[0045] According to the present invention, the epoxy resin with the structure shown in formula 1 is a resveratrol-based epoxy resin, and its preparation method preferably includes:

[0046] Add resveratrol and ECH to a four-neck round bottom flask equipped with mechanical stirring, constant pressure flow pump, thermometer and reflux device, the molar ratio of resveratrol and ECH is 1:6; and make it stir at 110 °C for 2 hour, the mixture was obtained, then, aqueous sodium hydroxide solution (20% w / w, 50mL) was added dropwise to the above mixture with a constant flow pump, and this process was controlled at 2-3 hours, and then the The mixture was reacted for 4 hours. In order to ensure that all phenolic hydroxyl groups were converted into glycidyl ether, 2 g of ferric chloride was added dropwise to the mixture, and the reaction was stopped when no color change was observed in the polymerization system, and then the reaction system was cooled to room temperature. The suspension w...

Embodiment 1

[0052] The preparation of embodiment 1 resveratrol-based epoxy resin

[0053] Add resveratrol (22.8g, 0.1mol) and ECH (55.5g, 0.6mol) in the 500mL four-neck round-bottom flask of assembly mechanical stirring, constant pressure flow pump, thermometer and reflux device, and make it at 110 ℃ Stir for 2 hours. Then, an aqueous sodium hydroxide solution (20% w / w, 50 mL) was added dropwise into the mixture at 110° C. with a constant flow pump, and the process was controlled for about 2 hours. The mixture was reacted at 110 °C for 4 h with vigorous stirring. In order to ensure that all the phenolic hydroxyl groups were converted into glycidyl ether, 2 g of ferric chloride was added dropwise to the mixture, and the reaction was stopped when no color change was observed in the polymerization system, and then the reaction system was cooled to room temperature. The suspension is diluted with about 50 ml of dichloromethane and the organic phase is extracted. After removing the upper aq...

Embodiment 2

[0055] The preparation of embodiment 2 carbon fiber composite material

[0056] (1) Take 58g of resveratrol-based epoxy resin, add 19g of DEDDM curing agent according to the proportion, stir and mix evenly, and then put it into a vacuum oven to remove the air bubbles in the resin.

[0057] (2) Cut 3k carbon fiber cloth with a strength level of T300 to make 3 carbon fiber boards, lay 12 layers of carbon fiber cloth on each board, cut 36 layers in total, and the size of each layer of carbon fiber cloth is 150×120mm; lay it flat in a vacuum bag;

[0058] (3) With the assistance of a vacuum pump, introduce the resin into 115g of carbon fiber, and keep the seal in a vacuum state.

[0059] (4) Put it in an oven, adjust the temperature to 75°C / 30min+110°C / 30min+160°C / 30min to complete the curing, remove the vacuum bag, take out the cured carbon fiber sample, and cut it into a sample of 120mm×12.5mm×3mm strips for bending tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com