Heat-shrinkage-resistant sealing ring and preparation method thereof

A heat-shrinkable sealing and rubber technology, which is applied in fiber types, textiles and papermaking, fiber processing, etc., can solve the problem that the performance of heat shrinkage resistance of seals is difficult to meet production requirements, and achieve excellent shrinkage resistance and excellent heat shrinkage resistance Performance and mechanical properties, excellent shrinkage resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

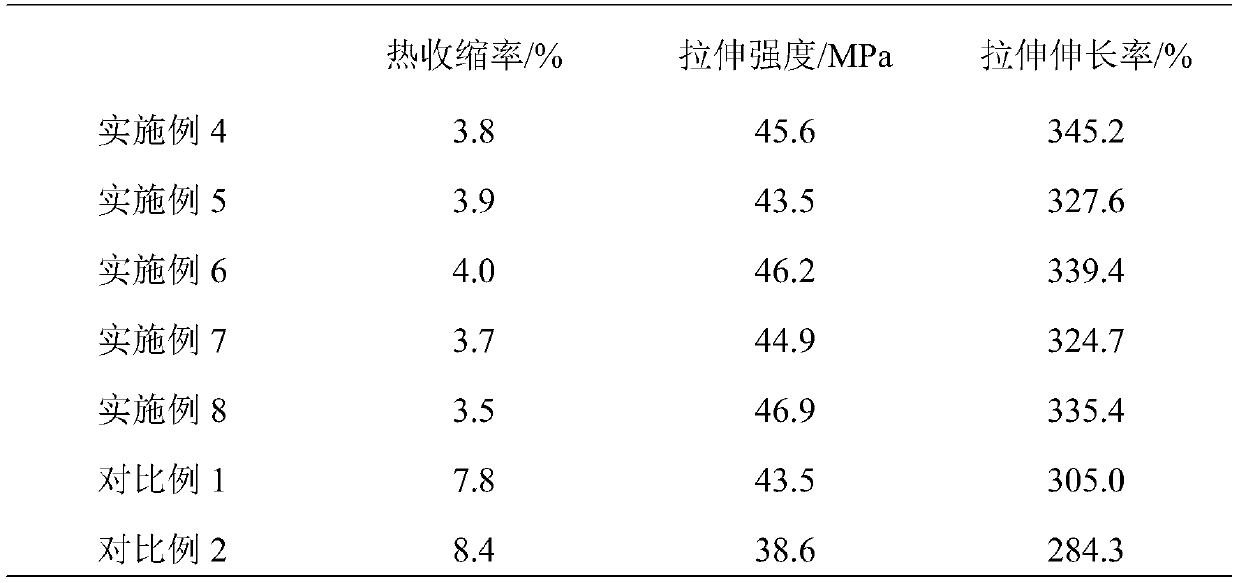

Examples

preparation example Construction

[0034] The modified fiber is used to improve the dimensional stability of the sealing ring and to improve the shrinkage resistance of the sealing ring. Preferably, the parts by weight of the modified fibers are 10-15 parts; more preferably, the parts by weight of the modified fibers are 12-13 parts. In an embodiment of the present invention, the modified fiber has a diameter of 10-41 μm and a length of 5-6 mm. Wherein, the modified fiber is a titanate-modified polypropylene fiber; the preparation method of the titanate-modified polypropylene fiber comprises the following steps: Add ester to dimethylacetamide solvent, stir evenly, add polypropylene fiber, soak at 40-50°C for 10-15h, and then dry at room temperature to obtain isopropyl tri(dioctyl coke Phosphate acyloxy) titanate modified polypropylene fiber.

[0035] Double-ended vinyl silicone oil is used to improve the toughness of rubber and improve the sealing performance of sealing rings. Preferably, the weight part of ...

Embodiment 1

[0046] The modified fiber is a titanate-modified polypropylene fiber, and the preparation method of the titanate-modified polypropylene fiber comprises the following steps:

[0047] Add isopropyl tris(dioctyl pyrophosphate acyloxy) titanate to dimethylacetamide solvent, stir evenly, add polypropylene fiber, soak at 40°C for 15h, and then dry at room temperature Dry, obtain diameter be 10 μ m, the polypropylene fiber that length is the isopropyl tris (dioctyl pyrophosphate acyloxy) titanate modification of 5mm; The weight-average molecular weight of polypropylene fiber is 50000;

[0048] The mass ratio of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate to polypropylene fiber is 0.1:1.

Embodiment 2

[0050] The modified fiber is a titanate-modified polypropylene fiber, and the preparation method of the titanate-modified polypropylene fiber comprises the following steps:

[0051] Add isopropyl tris(dioctyl pyrophosphate acyloxy) titanate to dimethylacetamide solvent, stir evenly, add polypropylene fiber, soak at 50°C for 10h, and then dry at room temperature Dry to obtain a diameter of 41 μm, a length of 6 mm isopropyl tris (dioctyl pyrophosphate acyloxy) titanate modified polypropylene fibers; the weight average molecular weight of the polypropylene fibers is 100,000;

[0052] The mass ratio of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate to polypropylene fiber is 0.2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com