A method for removing copper, lead and tellurium from copper smelting coarse selenium powder by controlled potential

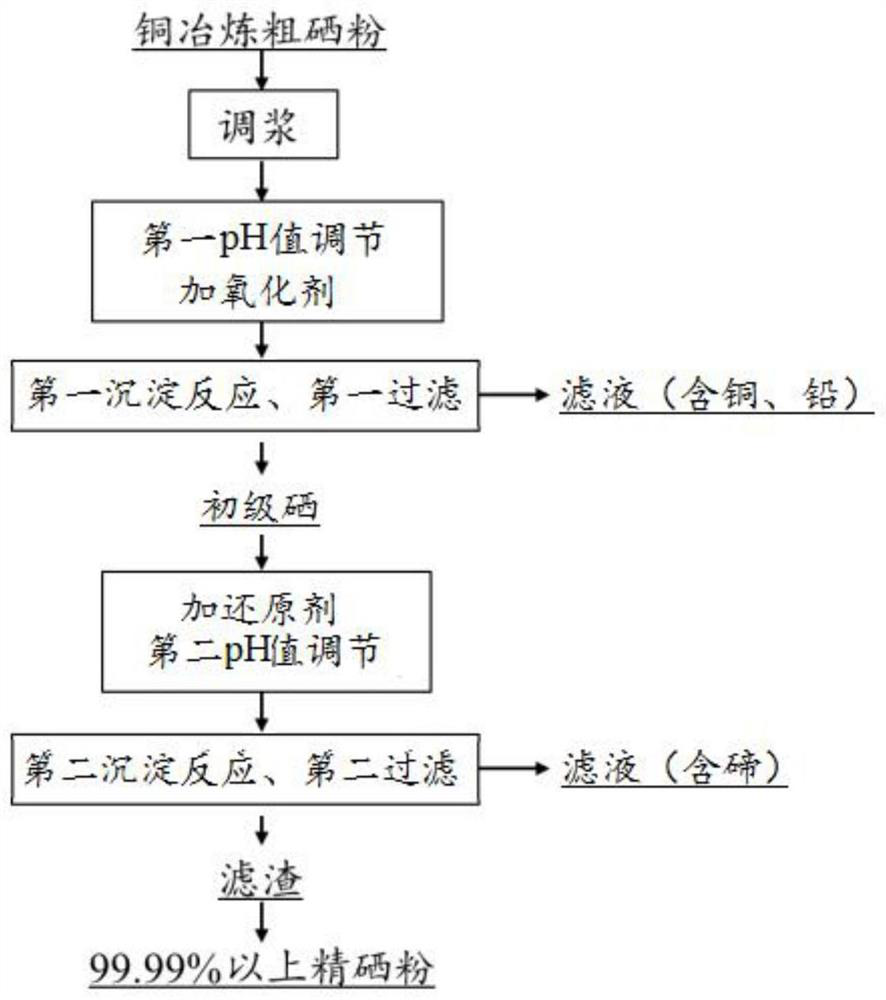

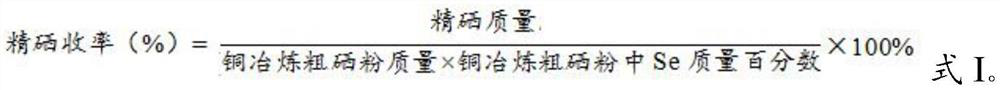

A technology for copper smelting and crude selenium, which is applied in the field of metallurgical impurity removal, can solve the problems of difficulty in further improving the purity of selenium, difficult to effectively remove, etc., and achieves the effects of easy operation, low selenium loss and high selenium purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Copper smelting coarse selenium powder includes the following components in mass percentage: Se 75.04%, Te 7.08%, Pb 2.78%, Cu 4.7%, and the balance is water, Fe and other impurities;

[0050] Add 1L of deionized water to 1kg of copper smelting coarse selenium powder, stir and adjust slurry to obtain selenium slurry;

[0051] Adding 390mL of dilute sulfuric acid with a mass concentration of 25% in the obtained selenium slurry, adjusting the pH value of the selenium slurry system to 1, and smelting crude selenium with 20mL / min / 1kg copper of 10% oxidant potassium permanganate solution with a mass concentration of 51mL The addition rate of the powder is added to the selenium mud and supplemented by 500rpm stirring, and the oxidation potential of the control system is 600mV, so that the impurities Cu and Pb are converted into soluble ions. After stirring for 1.5h, the material is press-filtered and washed to neutral to remove Cu. and Pb, to obtain primary selenium;

[0052...

Embodiment 2

[0059] Copper smelting coarse selenium powder includes the following components in mass percentage: Se 63.9%, Te 9.31%, Pb 2.78%, Cu 1.7%, and the balance is water, Fe and other impurities;

[0060] Add 0.5L of deionized water to 1kg of copper smelting coarse selenium powder, stir and adjust slurry to obtain selenium slurry;

[0061] Adding 260mL of mass concentration to the obtained selenium slurry is 30% dilute sulfuric acid to adjust the pH of the selenium slurry system to be 2, and 60mL of mass concentration is 15% oxidant sodium hypochlorite solution at a rate of 30mL / min / 1kg copper smelting coarse selenium powder Add selenium mud and stir at 500rpm, control the oxidation potential of the system to 500mV, convert impurities Cu and Pb into soluble ions, stir for 2 hours, press filter and wash the materials until neutral, thereby removing Cu and Pb, and obtaining primary selenium;

[0062] Adding 39mL of mass concentration to the primary selenium is 15% reductant ferrous c...

Embodiment 3

[0067] Copper smelting coarse selenium powder includes the following components in mass percentage: Se 78.9%, Te 8.31%, Pb 1.78%, Cu 4.7%, and the balance is water, Fe and other impurities;

[0068] Add 0.8L deionized water to 1kg copper smelting coarse selenium powder, stir and adjust the slurry to obtain selenium slurry;

[0069] Adding 305mL mass concentration to the obtained selenium mud is 28% dilute sulfuric acid, the pH of the adjustment system is 1.5, and 41mL mass concentration is 30% oxidant hydrogen peroxide solution with the addition rate of 50mL / min / 1kg copper smelting coarse selenium powder Add selenium mud and stir at 800rpm, control the oxidation potential of the system to 450mV, convert impurities Cu and Pb into soluble ions, stir for 1 hour, press filter and wash the material until neutral, thereby removing Cu and Pb, and obtaining primary selenium;

[0070] Add 68mL mass concentration to primary selenium and be the reductant ferrous sulfate solution of 20%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com