Mesoporous photo-thermal catalyst for dry reforming of medium-high temperature methane as well as preparation method and application thereof

A technology for methane dry reforming and catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. High chemical conversion efficiency, high catalytic conversion activity, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

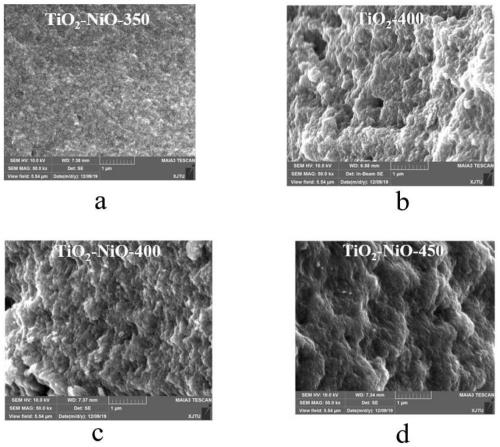

[0043] At room temperature, dissolve 0.75g of cetyltrimethylammonium bromide in 32ml of isopropanol solution, stir until completely dissolved, add 5g of tetra-n-butyl titanate, 1ml of glacial acetic acid, and stir for 0.5h A uniform light yellow solution A is formed; add 1.5ml of deionized water to 2ml of isopropanol to form a dropwise solution B; slowly drop B into solution A, stir and react at 30°C in a closed state for a certain period of time to obtain a uniform milky white TiO 2 Gel; aged for more than 48h, the obtained mesoporous TiO 2 The precursor gel was placed in a petri dish and dried at 100 °C, as image 3 As shown, the xerogel was calcined at 400 °C for 3 h to obtain white mesoporous TiO 2 Powder, its SEM picture is as follows figure 1 -b shown.

[0044] Then TiO 2 Immersed in a nickel nitrate solution with a concentration of 0.2wt%, dried the impregnated catalyst at 100°C for 2h, and calcined at 500°C for 5h to obtain Ni-mesoporous TiO with a pore size of 5....

Embodiment 2

[0046] Such as image 3 Shown, with embodiment 1, difference is to control mesoporous TiO 2 The calcination temperature of the precursor gel was 350°C to obtain 4.6nm pore size Ni-mesoporous TiO 2 Photothermal catalyst, its SEM picture is as follows figure 1 -a shown.

Embodiment 3

[0048] Such as image 3 Shown, with embodiment 1, difference is to control mesoporous TiO 2 The calcination temperature of the precursor gel was 450°C to obtain 8.4nm pore size Ni-mesoporous TiO 2 Photothermal catalyst, its SEM picture is as follows figure 1 -d shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com