Ultrasonic thermal expansion microcapsule and preparation method thereof

A technology of thermal expansion microcapsules and ultrasound, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of poor foaming uniformity, wide particle size distribution, high polymerization temperature, etc., and achieve high foaming ratio and molecular weight The effect of uniform distribution and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

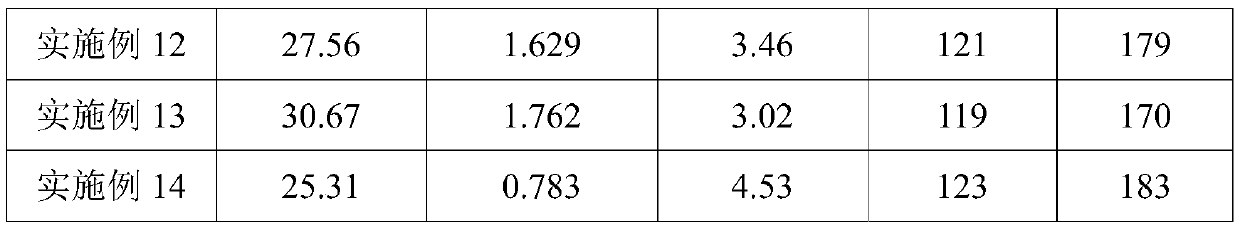

Examples

preparation example Construction

[0021] The first aspect of the present invention provides a kind of preparation method of ultrasonic thermal expansion microcapsule, at least comprises the following steps:

[0022] a) After mixing inorganic salt, suspending agent, auxiliary dispersant, polymerization inhibitor and deionized water, an aqueous phase composition is obtained;

[0023] b) After mixing low-boiling alkanes, polymerized monomers, initiators and crosslinking agents, an oil phase composition is obtained;

[0024] c) mixing the water phase composition and the oil phase composition, and preparing ultrasonic thermally expandable microcapsules through ultrasonic irradiation suspension polymerization.

[0025] In a preferred embodiment, the preparation method of the ultrasonically thermally expandable microcapsules at least includes the following steps:

[0026] a) After mixing the inorganic salt, suspending agent, auxiliary dispersant, polymerization inhibitor, and deionized water, adjust the pH to 2-3 wi...

Embodiment 1

[0103] Embodiment 1 of the present invention provides a kind of preparation method of ultrasonic thermal expansion microcapsule, comprises the following steps:

[0104] a) After mixing the inorganic salt, suspending agent, auxiliary dispersant, polymerization inhibitor, and deionized water, adjust the pH to 3 with phosphoric acid to obtain an aqueous phase composition;

[0105] b) After mixing low-boiling alkanes, polymerized monomers, initiators and crosslinking agents, an oil phase composition is obtained;

[0106] c) mixing the water phase composition and the oil phase composition, and preparing ultrasonic thermally expandable microcapsules through ultrasonic irradiation suspension polymerization.

[0107] In parts by weight, 200 parts of inorganic salts, 40 parts of suspending agents, 3 parts of auxiliary dispersants, 0.5 parts of polymerization inhibitors, 600 parts of deionized water, 40 parts of low boiling point alkanes, 200 parts of polymerization monomers, 2 parts of...

Embodiment 2

[0124] Embodiment 2 of the present invention provides a kind of preparation method of ultrasonic thermal expansion microcapsule, comprises the following steps:

[0125] a) After mixing the inorganic salt, suspending agent, auxiliary dispersant, polymerization inhibitor, and deionized water, adjust the pH to 3 with phosphoric acid to obtain an aqueous phase composition;

[0126] b) After mixing low-boiling alkanes, polymerized monomers, initiators and crosslinking agents, an oil phase composition is obtained;

[0127] c) mixing the water phase composition and the oil phase composition, and preparing ultrasonic thermally expandable microcapsules through ultrasonic irradiation suspension polymerization.

[0128] In parts by weight, 100 parts of inorganic salt, 10 parts of suspending agent, 0.05 part of auxiliary dispersant, 0.1 part of polymerization inhibitor, 200 parts of deionized water, 20 parts of low boiling point alkane, 100 parts of polymerized monomer, 0.1 part of initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com