Preparation method of nanocapsules carrying fat-soluble active substances

An active, fat-soluble technology, used in organic active ingredients, preparations for skin care, medical preparations with non-active ingredients, etc., can solve the problems of affecting the use effect, unstable nanocapsule ions, etc. Beneficial for transdermal absorption and good occlusive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Isopropyl myristate: 3g

[0029] Cetyl Palmitate: 7g

[0030] Coenzyme Q10: 2.5g

[0031] PC60: 3g

[0032] Glycerin: 20g

[0033] Water: balance, a total of 100g

[0034] Mix PC60, hexaglyceryl monolaurate, glycerin and water, and magnetically stir in a water bath at 80°C until the water phase is clear and transparent; mix caprylic capric triglyceride, cetyl palmitate, and fat-soluble active substances , heat and dissolve in a water bath at 80°C until the oil phase is clear and transparent; add the water phase to the oil phase, disperse at 10,000rpm at a high speed, disperse for 3min, then use a high-pressure homogenizer at 60MPa, circulate 6 times, and cool at room temperature to prepare the carrier Nanocapsules of curcumin.

[0035] The obtained nanocapsules are milky, the loading capacity of coenzyme Q10 is 2.5%, and the encapsulation efficiency is about 99.6%. The particle size measured by Zeta potential and nano particle size analyzer is 150nm, and the partic...

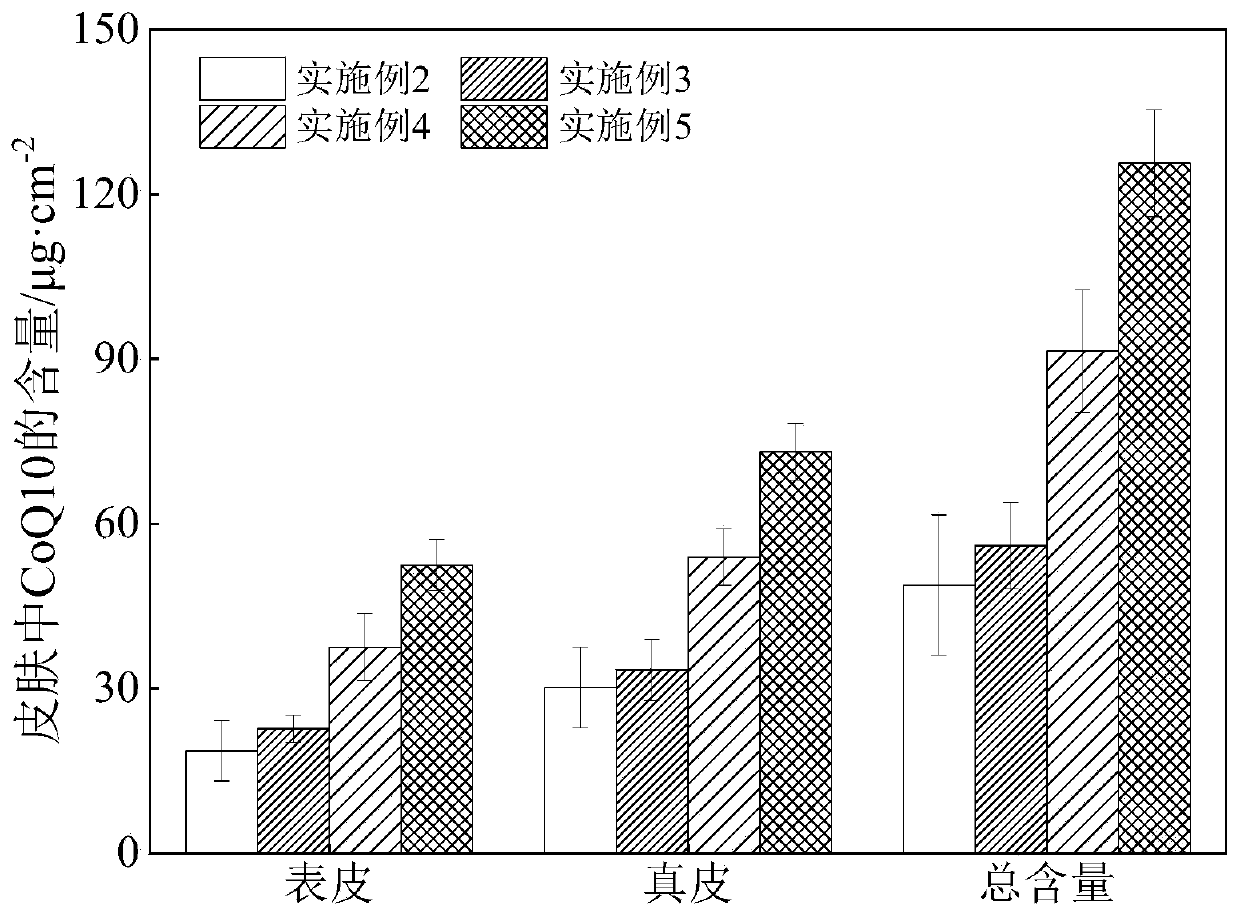

Embodiment 2

[0037] Caprylic capric triglyceride:: 5g

[0038] Coenzyme Q10: 5g

[0039] PC60: 2g

[0040] Ten polyglyceryl monolaurate: 3g

[0041] Glycerin: 70g

[0042] Water: balance, a total of 100g

[0043] Mix PC80, decaglycerol monomyristate, glycerin and water, and magnetically stir in a water bath at 60°C until the water phase is clear and transparent; mix caprylic capric triglyceride and coenzyme Q10, and heat in a water bath at 60°C Dissolve until the oil phase is clear and transparent; add the water phase to the oil phase, disperse at 15,000rpm at a high speed, disperse for 2 minutes, then use a high-pressure homogenizer at 80MPa, cycle 3 times, and cool at room temperature to prepare nanocapsules carrying coenzyme Q10.

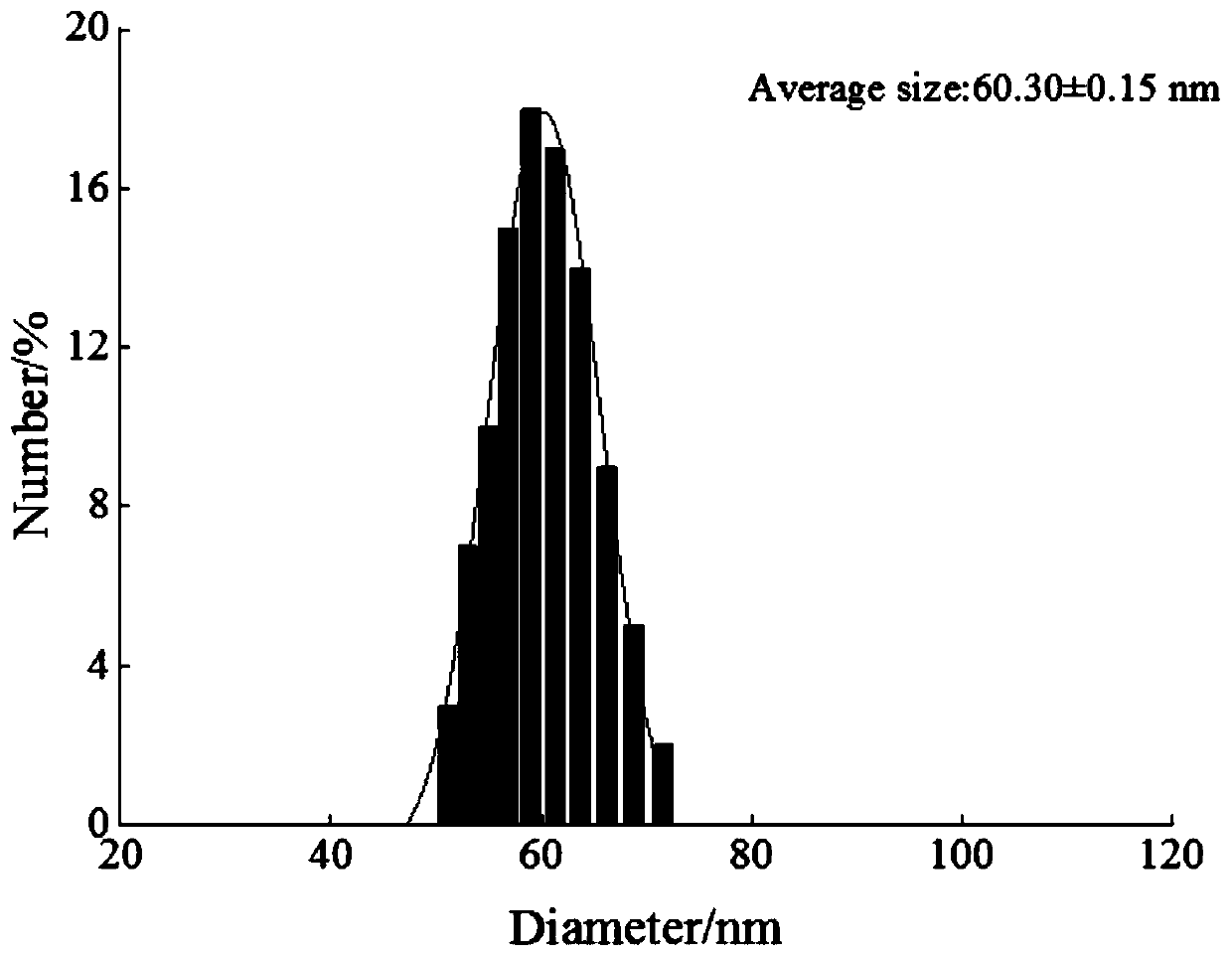

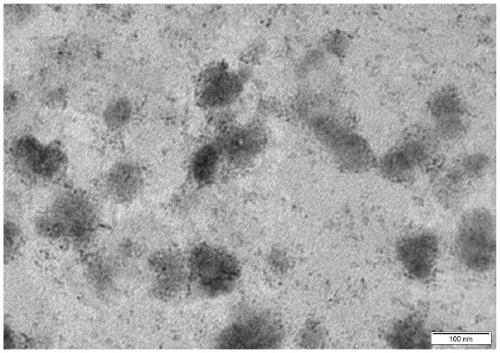

[0044] The obtained nanocapsules are transparent liquid, the loading capacity of coenzyme Q10 is 5%, and the encapsulation efficiency is about 99.2%. The particle size is 59nm measured by Zeta potential and nano particle size analyzer. After 90 days at room...

Embodiment 3

[0046] Caprylic Capric Triglyceride: 2.5g

[0047] Glyceryl Cetyl Palmitate: 2.5g

[0048] Coenzyme Q10: 5g

[0049] PC60: 2g

[0050] Ten polyglyceryl monolaurate: 3g

[0051] Glycerin: 70g

[0052] Water: balance, a total of 100g

[0053] Mix PC80, decaglycerol monomyristate, glycerin and water, and magnetically stir in a water bath at 60°C until the water phase is clear and transparent; mix caprylic capric triglyceride and coenzyme Q10, and heat in a water bath at 60°C Dissolve until the oil phase is clear and transparent; add the water phase to the oil phase, disperse at 15,000rpm at a high speed, disperse for 2 minutes, then use a high-pressure homogenizer at 80MPa, cycle 3 times, and cool at room temperature to prepare nanocapsules carrying coenzyme Q10.

[0054] The obtained nanocapsule is a transparent liquid, the coenzyme Q10 load is 5%, and the encapsulation efficiency is about 99.5%. The differential scanning calorimetry (DSC) results show that the solid lipid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com