Novel tea leaf production method for removing pollutants inside and outside tea leaves

A technology of pollutants and new methods, applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of high water content on the leaf surface, reducing the fluorine content of tea leaves, loss of beneficial components, etc. Rapid dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

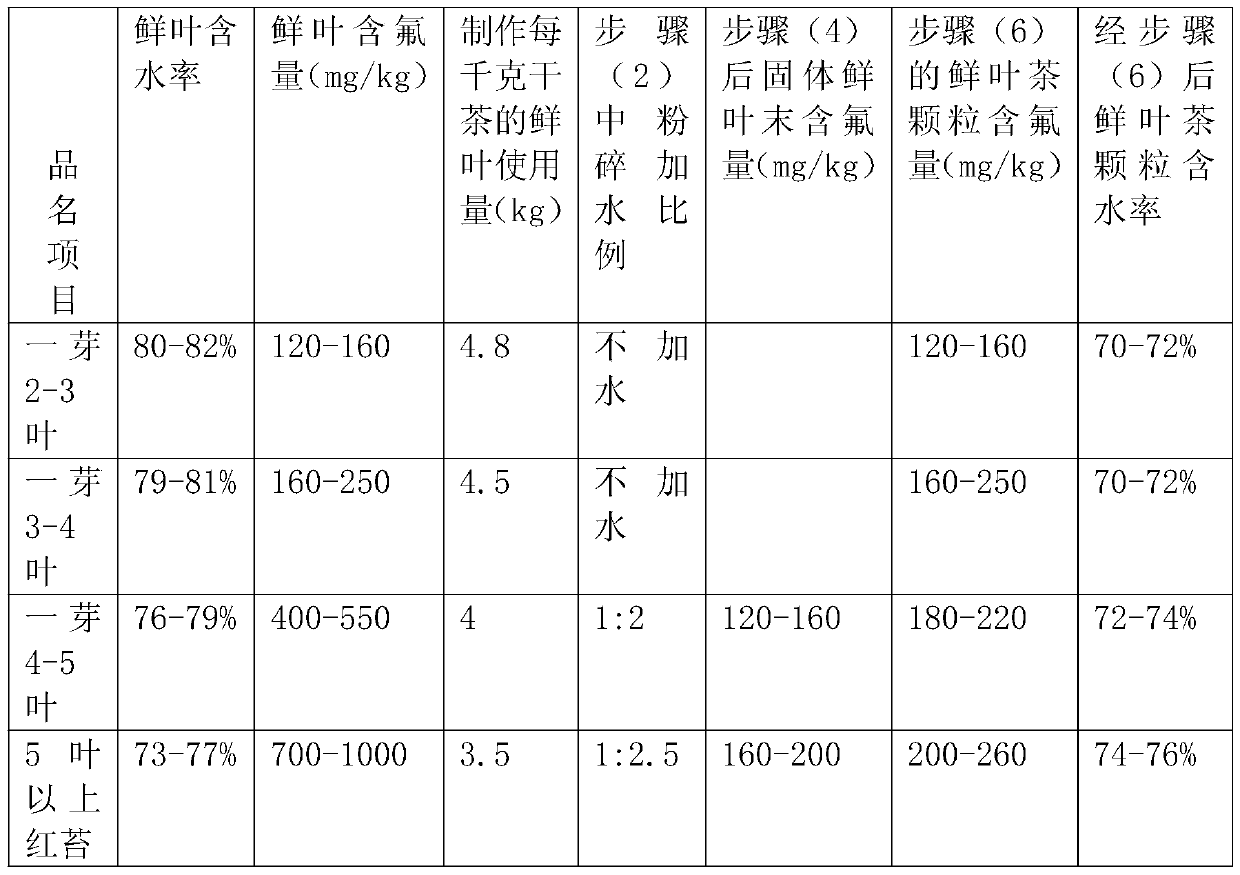

Image

Examples

Embodiment 1

[0047] A new tea production method for removing internal and external pollutants from tea leaves comprises the following steps in sequence:

[0048] (1) Washing fresh leaves: the fresh leaves picked into the factory (collected from Ya'an Yixing Tibetan Tea Co., Ltd.), one bud has four to five leaves, and the growth cycle is 35 days to 40 days. After measurement, the fluorine content is 501mg / kg The fresh leaves (that is, the fresh leaves are dried to make dry tea to measure the fluorine content) are sent to the tea washing machine by the conveyor belt for full and continuous stirring and washing. The method of combining washing, stirring and rubbing the foreign pollutants adhered to the surface of the tea leaves, the cleaning tank is 1.1 meters wide and 4.5 meters long, the output per hour is 1500-2000 kg, continuous production, the decontamination ability reaches 80%, and the cleaning effect is good), Obtain washed clean fresh leaves;

[0049] (2) Crushing and refining: Send...

Embodiment 2

[0056] A new tea production method for removing internal and external pollutants from tea leaves comprises the following steps in sequence:

[0057] (1) Washed fresh leaves: the fresh leaves picked into the factory (collected from Ya'an Yixing Tibetan Tea Co., Ltd.), with red moss of more than five leaves, and a growth cycle of more than 2 months. After testing, the fresh leaves with a fluorine content of 760mg / kg Leaves are sent to the tea washing machine through the conveyor belt for full and continuous stirring and washing. , the cleaning tank is 1.1 meters wide, 4.5 meters long, and the output per hour is 1500-2000 kilograms, continuous production, the decontamination ability reaches 80%, and the cleaning effect is good), to obtain washed clean fresh leaves;

[0058] (2) Crushing and refining: Send the clean fresh leaves obtained in step (1) to a 55KW-600 hammer mill for pulverization. Add 2.5 kilograms of water per kilogram of fresh leaves to obtain an aqueous solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com