Showerhead and substrate processing apparatus

一种基板处理装置、喷淋头的技术,应用在气态化学镀覆、涂层、电气元件等方向,能够解决高电阻、增加机械性破损等问题,达到容易调节、容易工序均匀度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, refer to the attached Figure 1 to Figure 8 Preferred embodiments of the present invention are described in more detail. The embodiments of the present invention can be modified into various forms, and the scope of the present invention should not be construed as being limited to the embodiments described below. This embodiment is provided in order to explain the present invention in more detail to those skilled in the art. Therefore, the shape of each element appearing in the drawings may be exaggerated in order to emphasize clearer description.

[0032] In addition, a vapor deposition apparatus will be described below as an example, but the scope of the present invention is not limited thereto, and it can be applied to various processes of processing a substrate with a reactive gas.

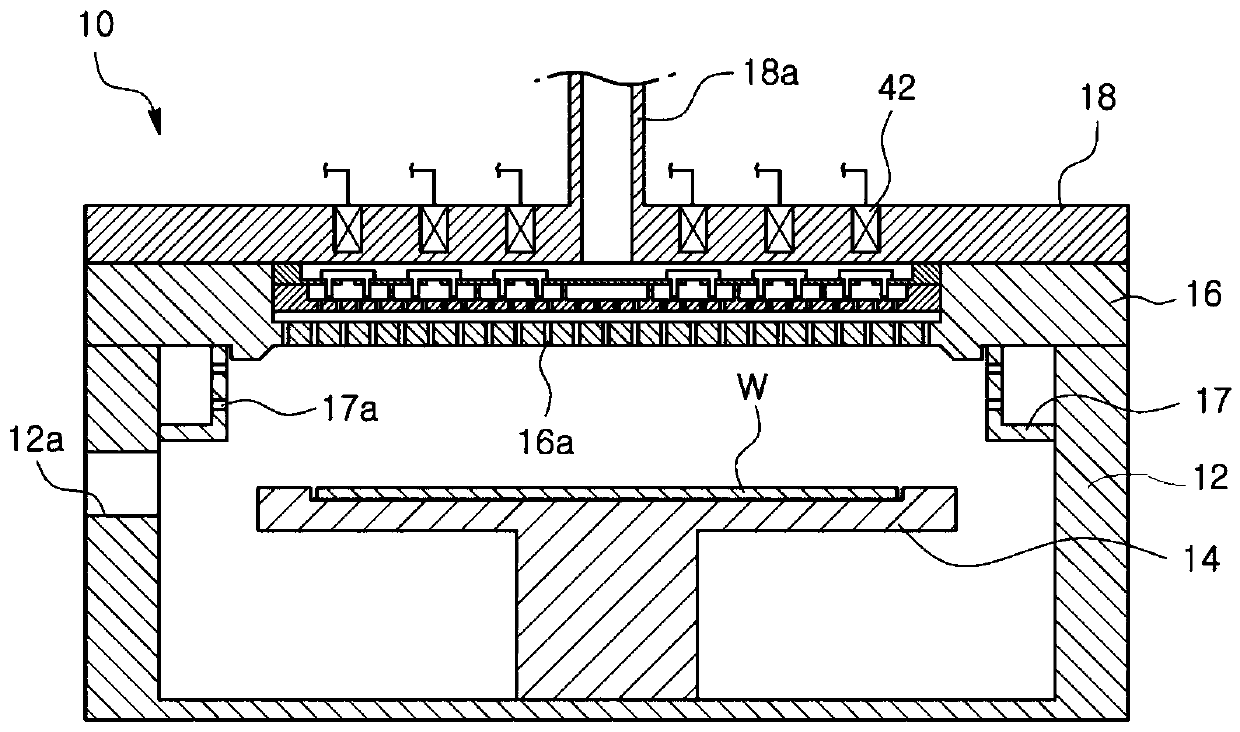

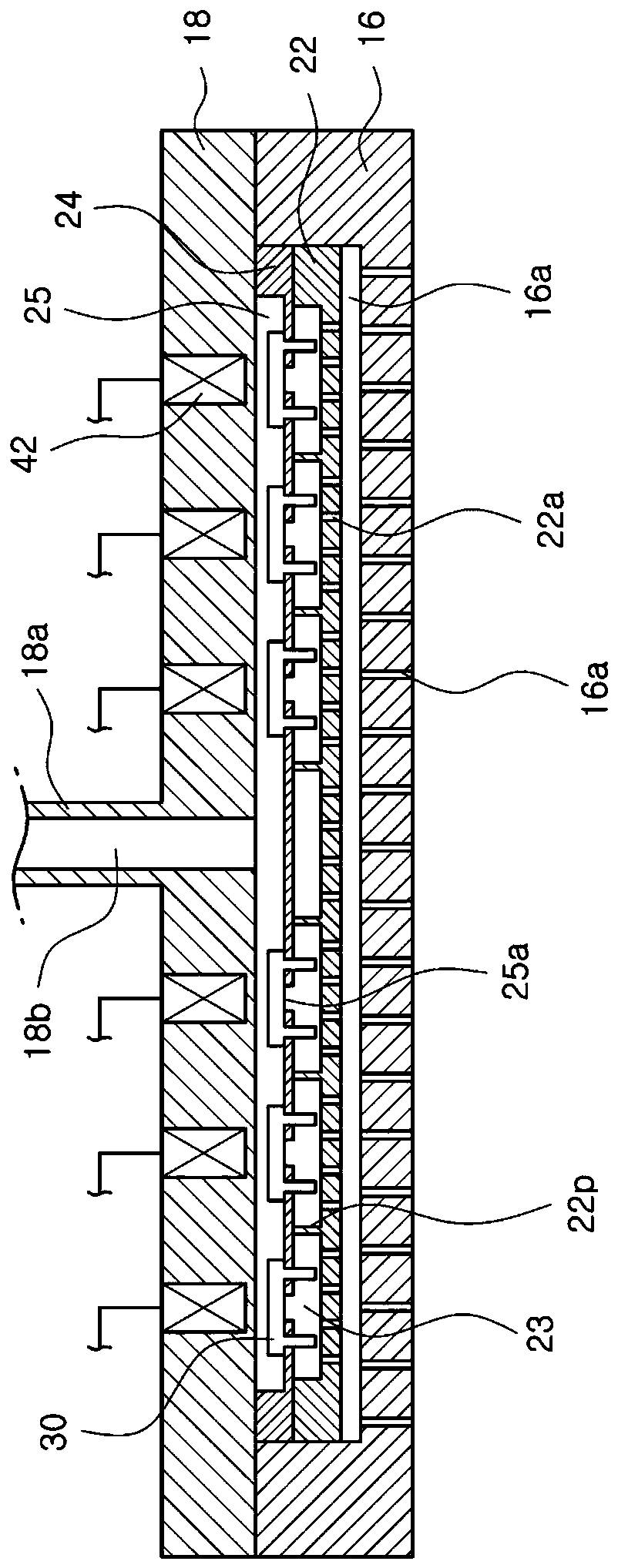

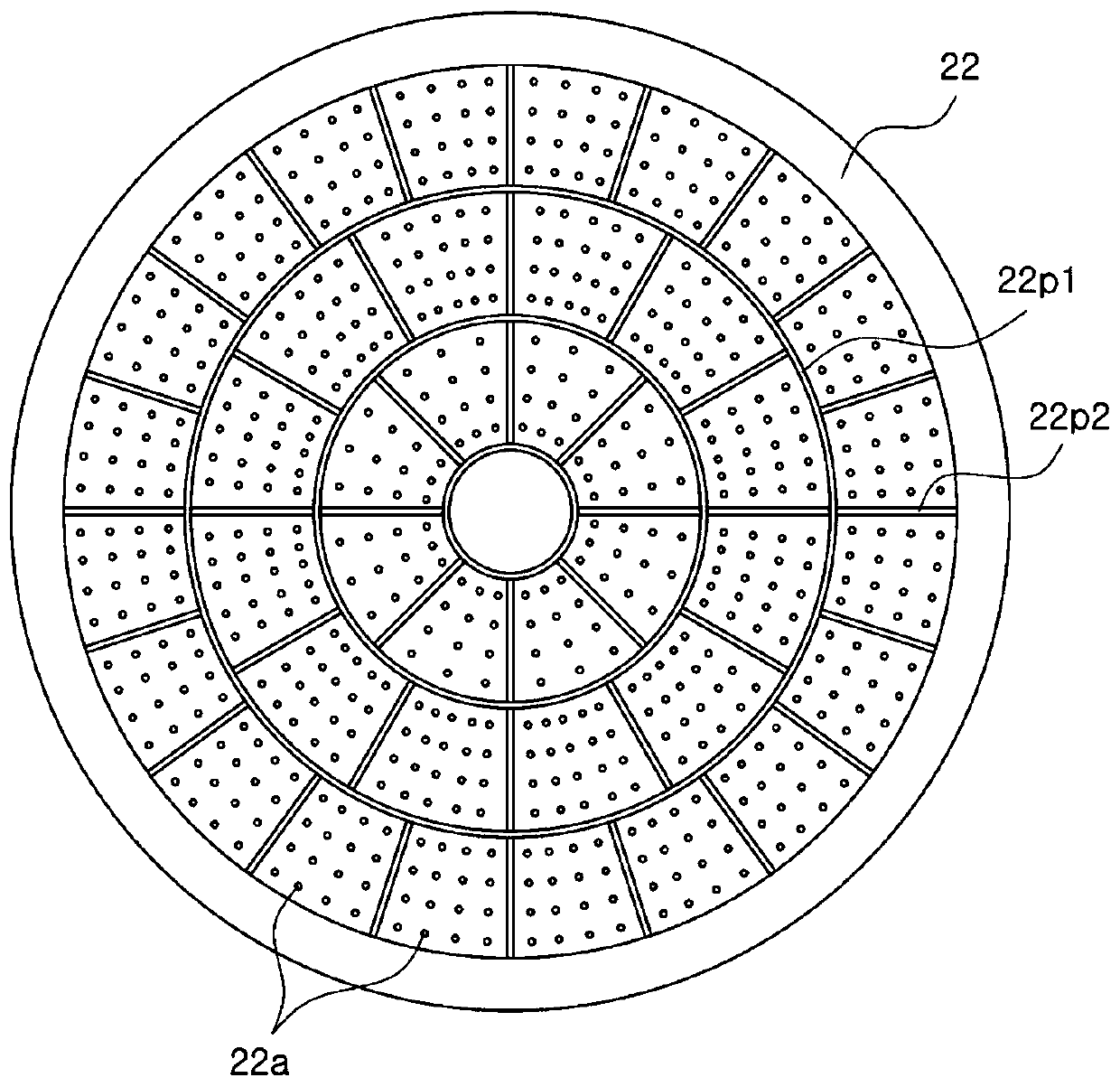

[0033] figure 1 is a cross-sectional view schematically showing a substrate processing apparatus according to an embodiment of the present invention. Such as figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com