Turbine front-back switchable SCR denitration system

A SCR system, switchable technology, applied in the field of switchable SCR denitrification system before and after the vortex, can solve the problems such as difficult to meet the requirements of tail gas treatment, insufficient temperature, etc., to avoid the decline of purification effect, avoid waste, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the switchable SCR denitrification system provided by the embodiments of the present disclosure, the reaction temperature of the catalytic reduction reaction in the SCR system is ensured by switching the intake sequence of the turbine and the SCR system, thereby ensuring the treatment efficiency of engine exhaust gas.

[0039] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

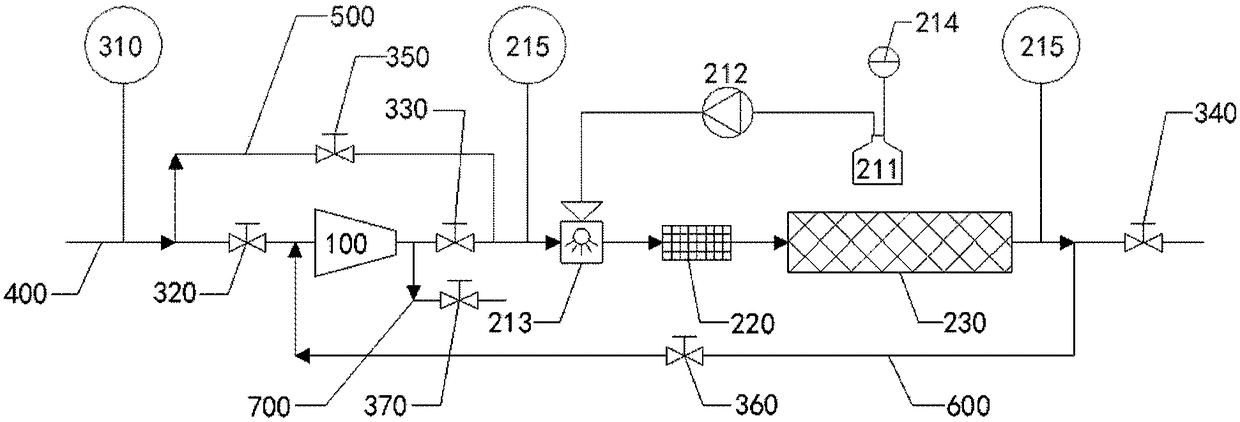

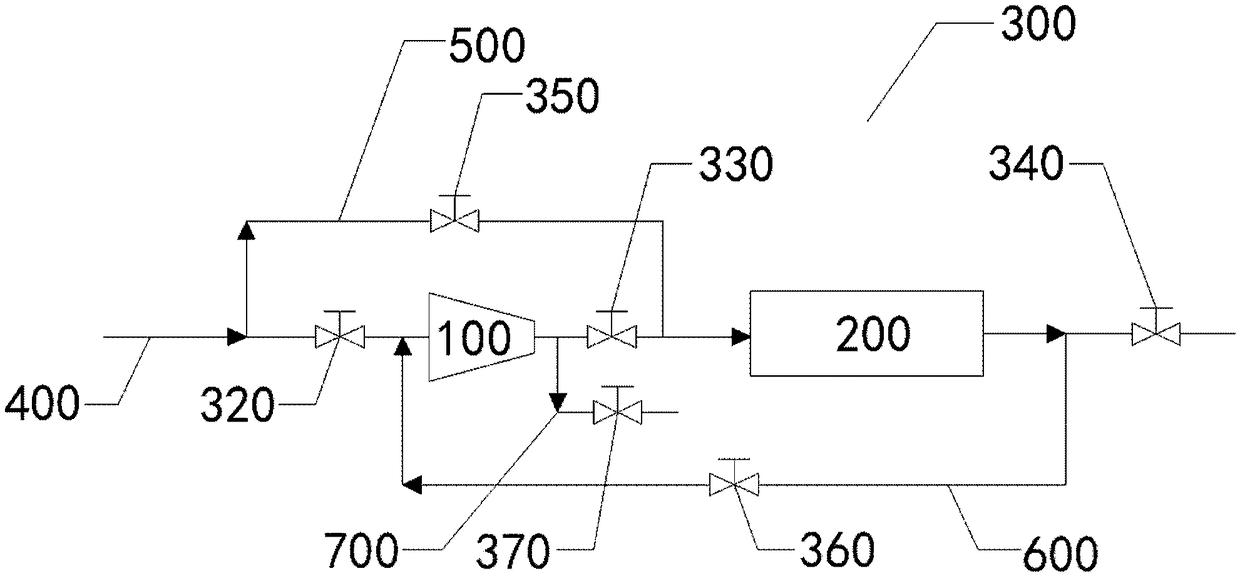

[0040] figure 1 It is a structural schematic diagram of the switchable SCR denitrification system of the present disclosure.

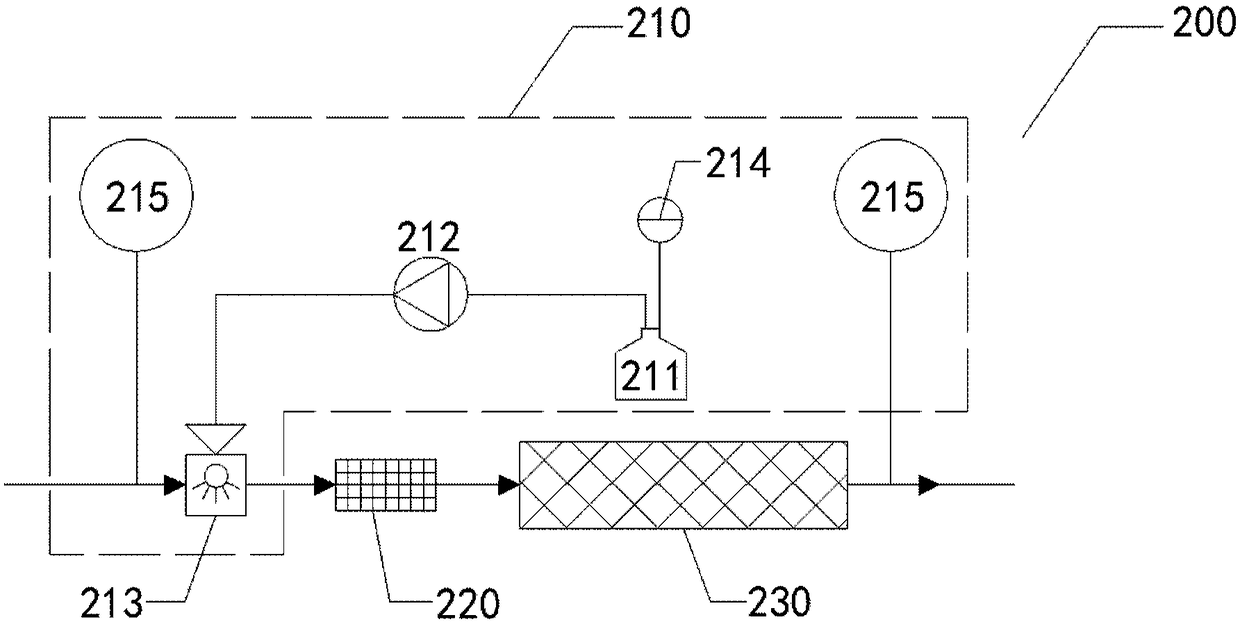

[0041] The present disclosure provides a switchable SCR denitrification system before and after the vortex, such as figure 1As shown, it includes: a turbine 100, which is driven by airflow to do work; an SCR system 200, which is connected in series with the turbine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com