Substrate cleaning device

A technology for cleaning devices and substrates, applied in cleaning methods and utensils, cleaning methods using liquids, electrical components, etc., can solve problems such as scattering, and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

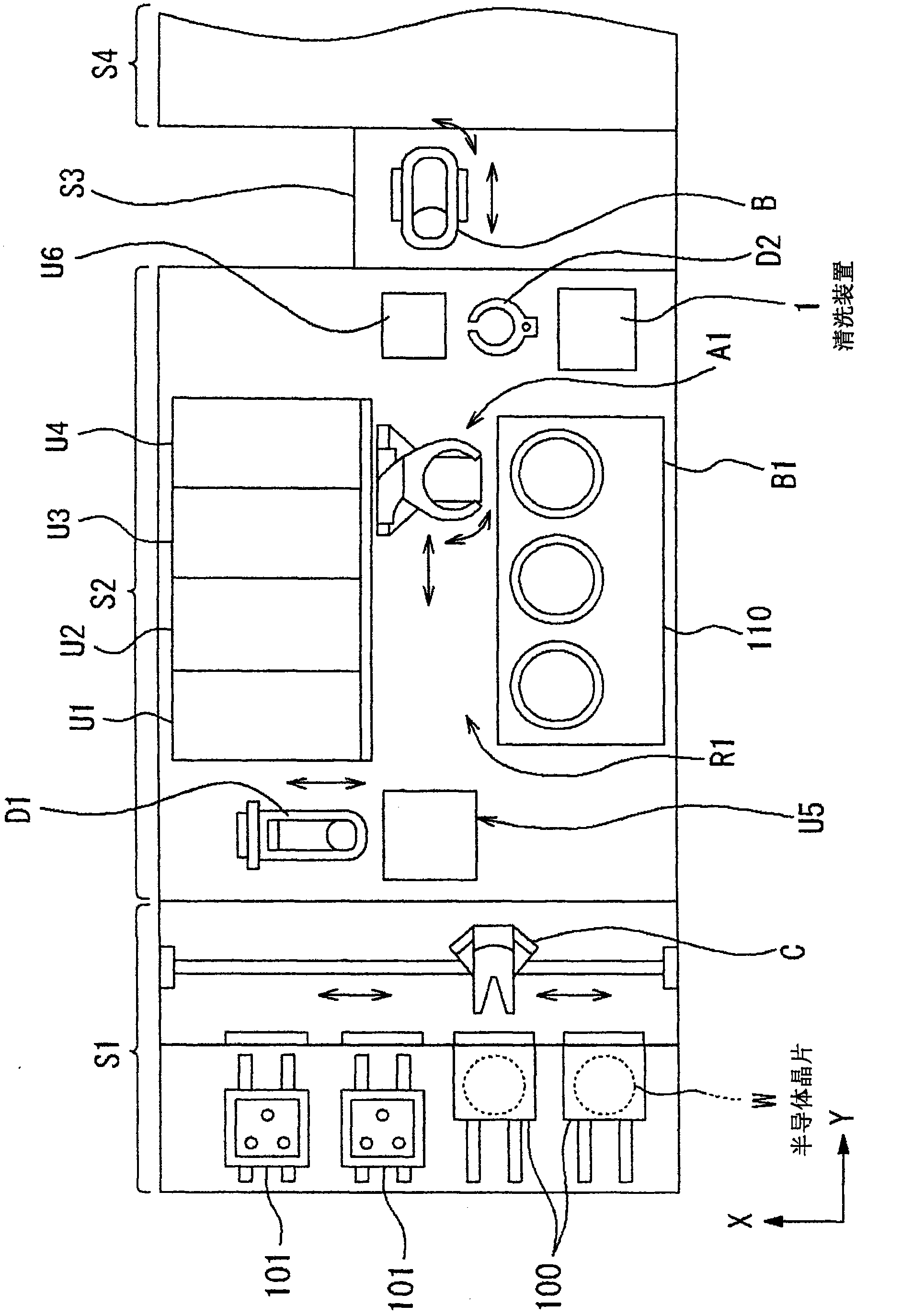

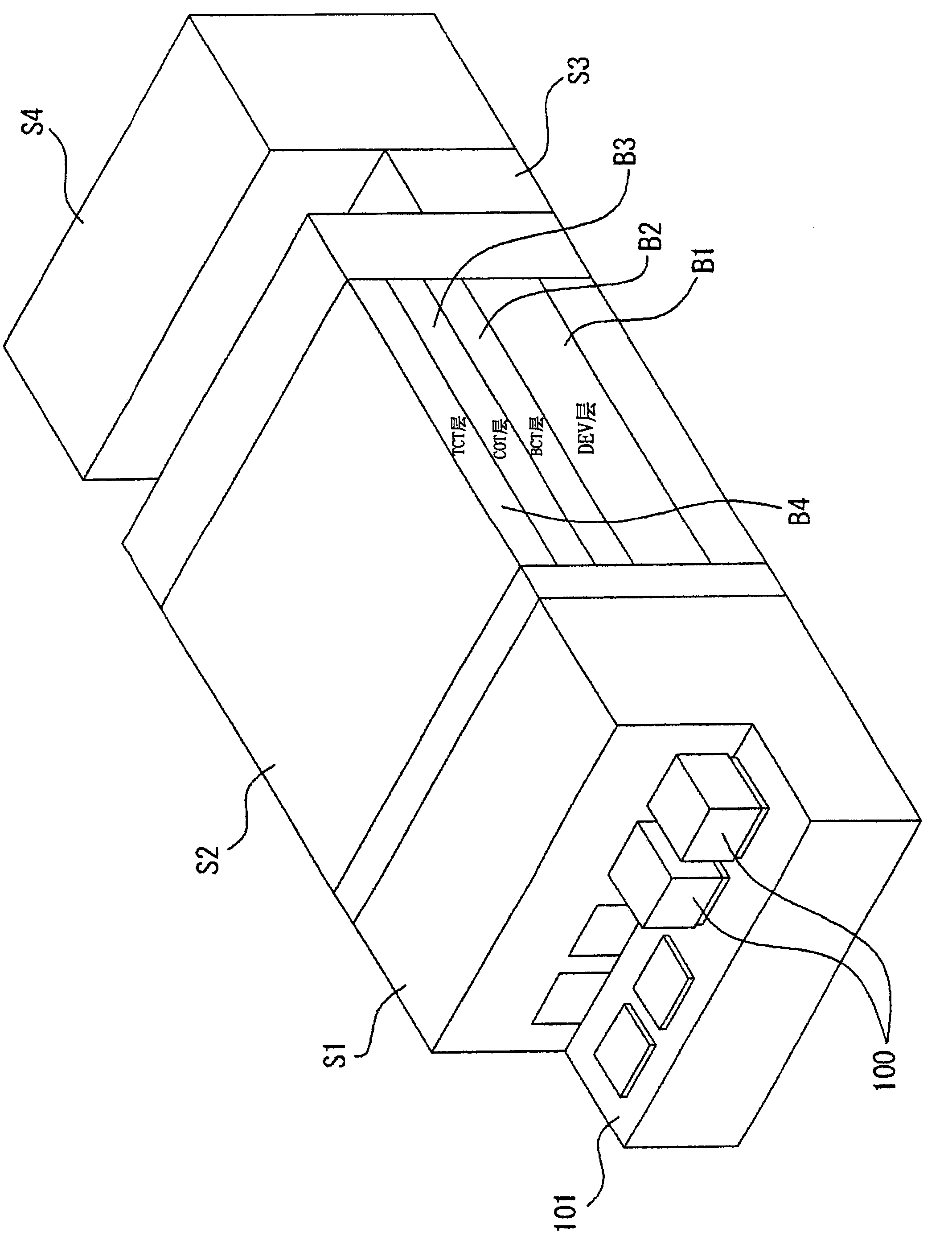

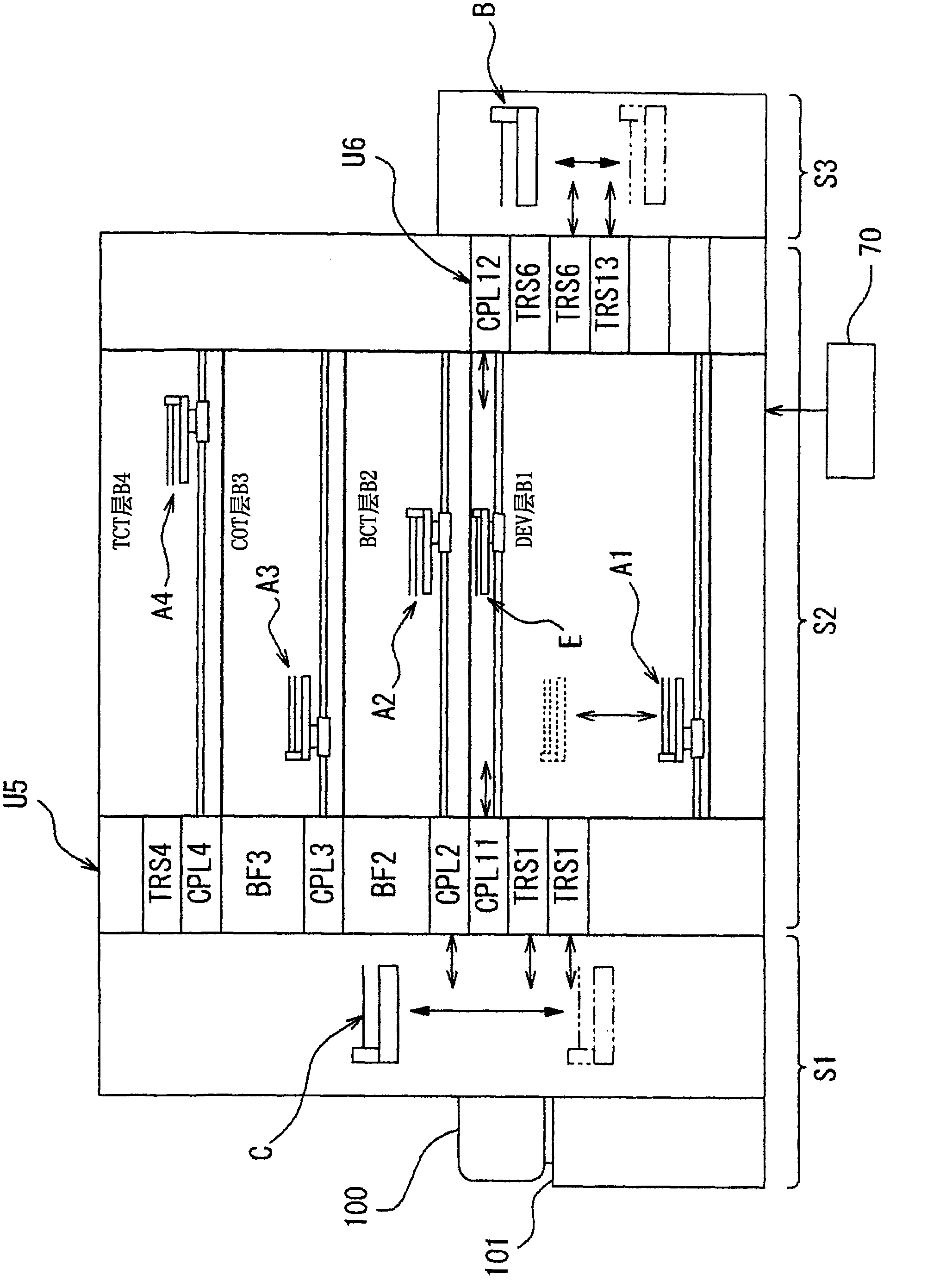

[0077] Figure 4 It is a perspective view (a) of the cleaning device 1 and an enlarged perspective view (b) of part I of (a), Figure 5 is a plan view of the cleaning device 1, Figure 6 is a longitudinal sectional view of the cleaning device 1 .

[0078] The cleaning device 1 adopts the following structure, and is installed on the box-shaped lower cover 40 with the upper surface open: the wafer W received from the above-mentioned second delivery arm D2 in the resist solution coating and development processing system is held approximately horizontally as the first wafer W. the suction pad 10 of the substrate holding unit; the spin chuck 20 functioning as the second substrate holding unit that receives the wafer W from the suction pad 10 and then holds the wafer W approximately horizontally in the same manner; and cleaning of the back surface of the wafer W Part 30.

[0079] Such as Figure 4 As shown, two adsorption pads 10 are provided in the cleaning device 1, and each a...

no. 2 approach

[0112] Figure 19 It is a schematic cross-sectional view showing a second embodiment of the cleaning device of the present invention.

[0113] The second embodiment is a case where the particles removed by the cleaning member 30 and the cleaning liquid used for cleaning are actively discharged. That is, if Figure 19 As shown, the drain pipe 81 is communicated (connected) with each discharge hole 36 provided in the cleaning unit 30, and the drain pipe 81 is connected with the suction pump 80 as a suction unit to actively discharge the particles removed by the cleaning unit 30. and cleaning fluid for cleaning. In this case, the servo motor 39 which is the rotation mechanism of the suction pump 80 and the cleaning member 30, and the flow rate adjustment valve 53 provided in the cleaning liquid supply pipe 51 are electrically connected to the controller 70 as a control unit, and based on the The control signal is controlled. In addition, in 2nd Embodiment, other parts are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com