High-speed rolling bearing lubrication device

A bearing lubrication and high-speed rolling technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of inner ring wear and scorching, reduction of lubricating oil, damage to bearing performance, etc., to improve service life and work performance, avoiding too little lubricating oil, and the effect of low temperature rise of the inner ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

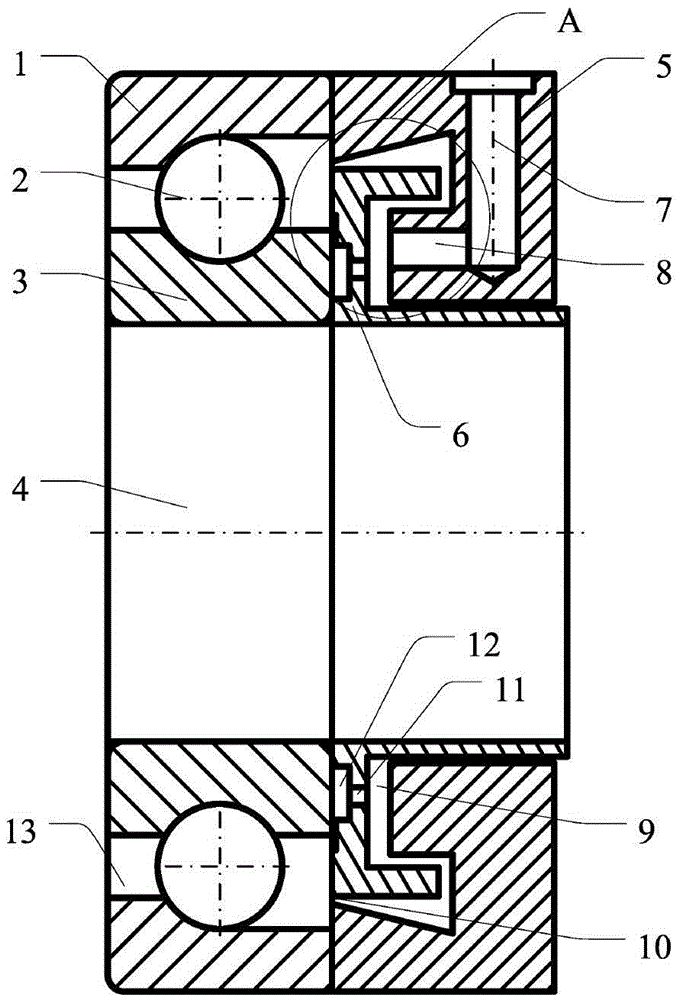

[0016] See attached figure 1 , 2 , a high-speed rolling bearing lubrication device, which includes: a bearing, an oil inlet sleeve 5 and an oil distribution sleeve 6; the bearing further includes: a bearing outer ring 1, a rolling body 2, and a bearing inner ring 3;

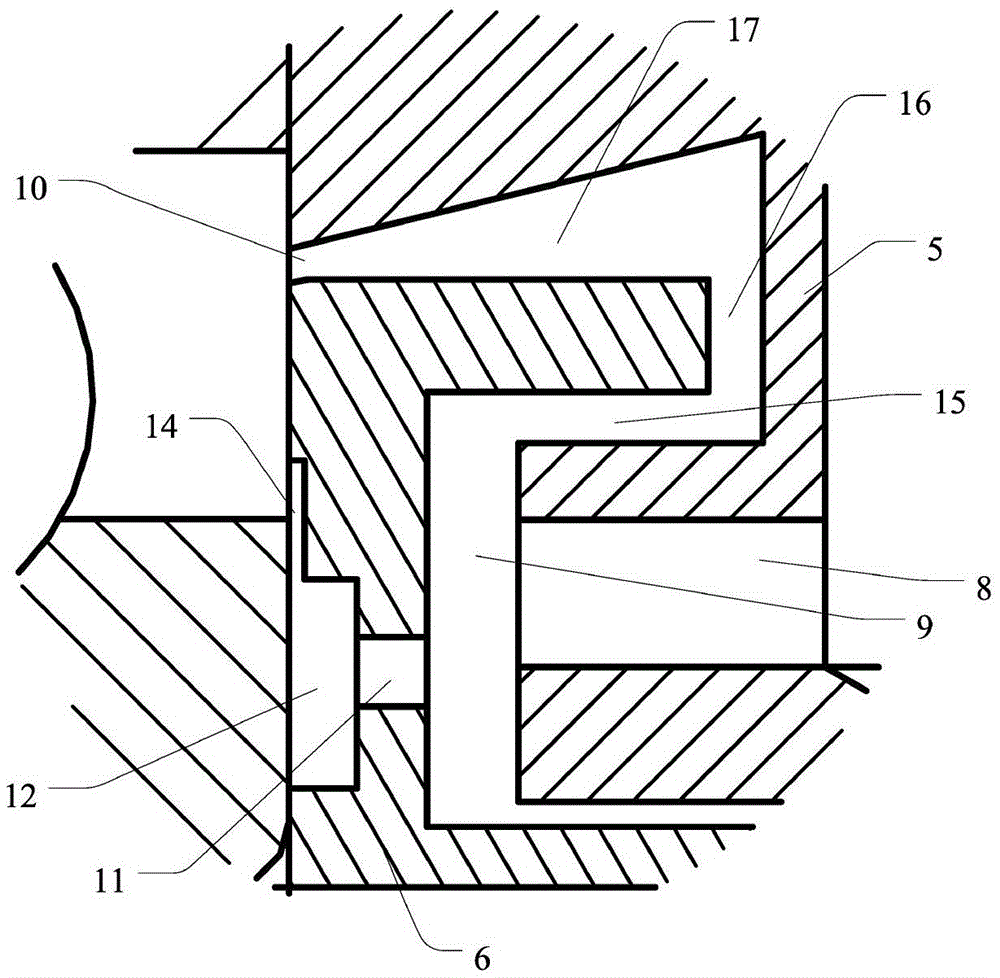

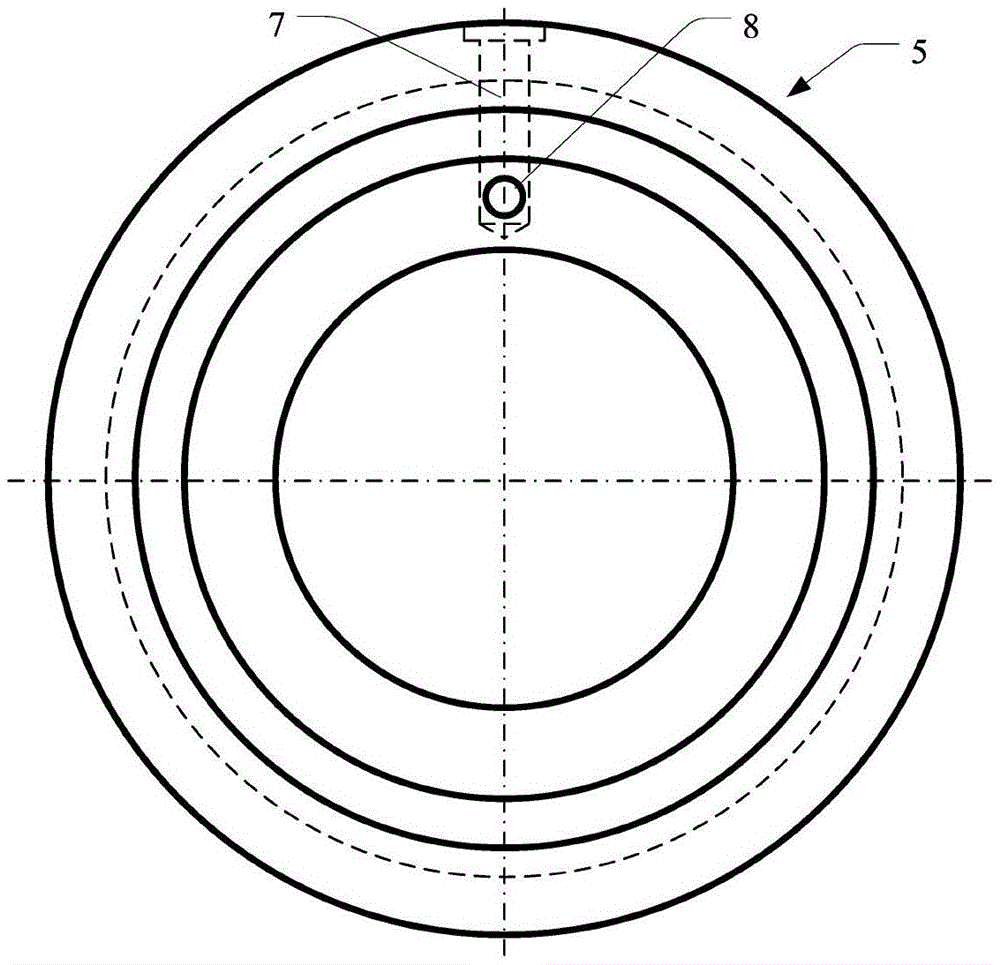

[0017] See attached image 3 , one end surface of the oil inlet sleeve 5 is provided with an annular groove, and the annular groove divides the oil inlet sleeve 5 into two parts, the inner ring and the outer ring, and the height of the inner ring in the axial direction is lower than that of the outer ring in the axial direction , and the inner wall of the outer ring is a slope; the inner ring of the oil inlet sleeve 5 is provided with a horizontal main oil passage 8, and the outer ring of the oil inlet sleeve 5 is provided with an oil inlet hole 7 vertically connected with the horizontal main oil passage 8 ;

[0018] See attached Figure 4 , one end surface of the oil distribution sleeve 6 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com