Porous array lubricating device for high-speed rolling bearing

A technology of porous array and lubricating device, which is applied to rolling contact bearings, rotating bearings, bearings, etc., can solve problems such as affecting the working performance of the transmission system, damage to the performance of the bearing, wear and anxiety of the inner ring, etc., to improve the service life. and working performance, uniform lubrication, avoiding the effect of too little lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

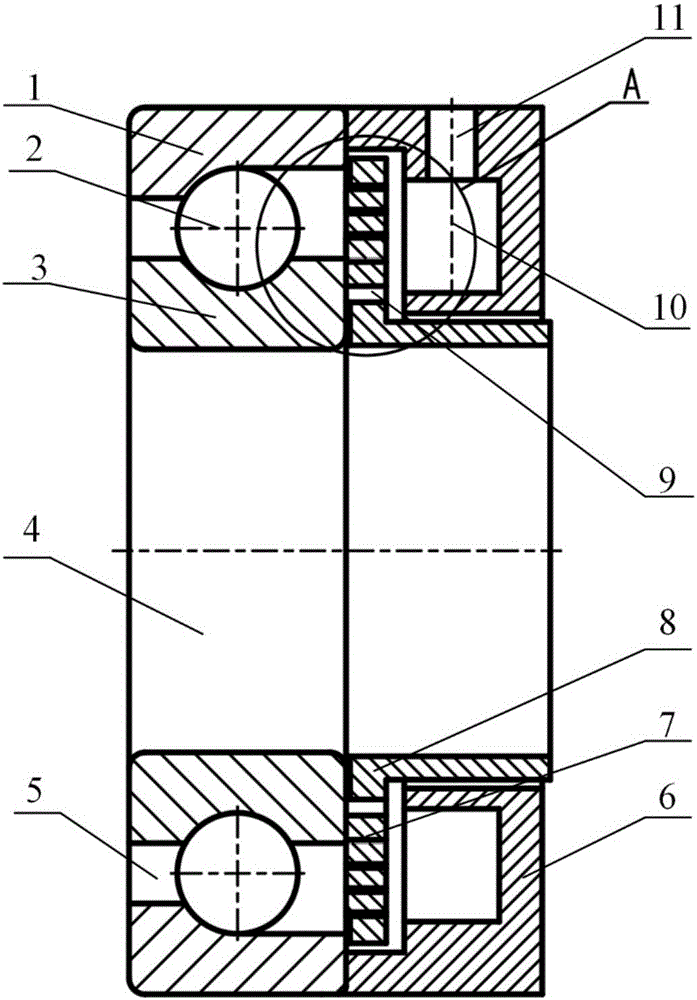

[0014] See attached figure 1 , 2 , a multi-hole array lubrication device for high-speed rolling bearings, comprising: an oil inlet sleeve 6 and an oil distribution sleeve 8;

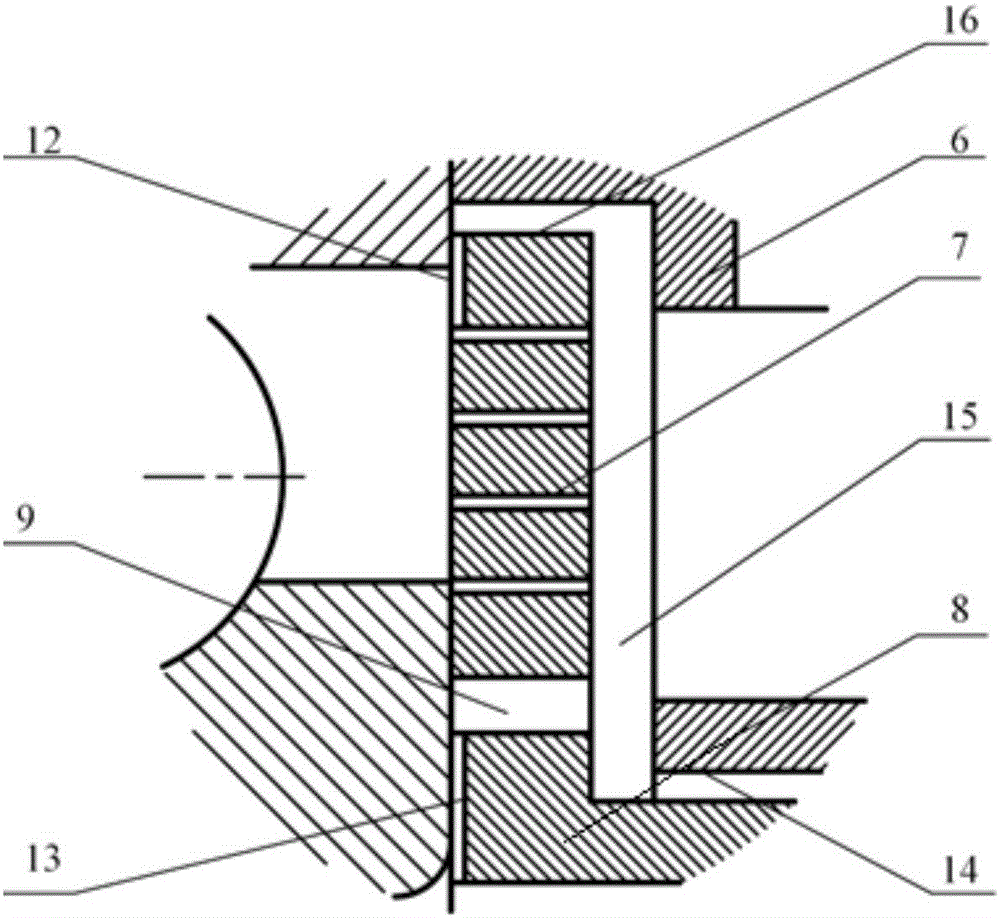

[0015] See attached figure 1 , 3 , the oil inlet sleeve 6 is provided with an annular oil storage chamber 10 and an oil inlet passage 11 communicating with the oil storage chamber 10;

[0016] On the end surface of the oil distribution sleeve 8, there are a plurality of heat dissipation oil storage holes 9 of the inner ring and oil injection hole groups corresponding to the heat dissipation oil storage holes 9 of the inner ring evenly distributed along its circumferential direction; Figure 4 As shown: four oil injection holes 7 form a group; each oil injection hole group is arranged outside an inner heat dissipation oil storage hole 9, and the oil injection holes 7 in each group are arranged in a straight line (in the radial direction) at equal intervals ;

[0017] The oil distribution sleeve 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com