Preparation method of N-type battery and selective emitter of N-type battery, and N-type battery

A selective and emitter technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of heavy boron doping of N-type batteries, successful reports of no laser doping, etc., and achieve the effect of increasing the open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

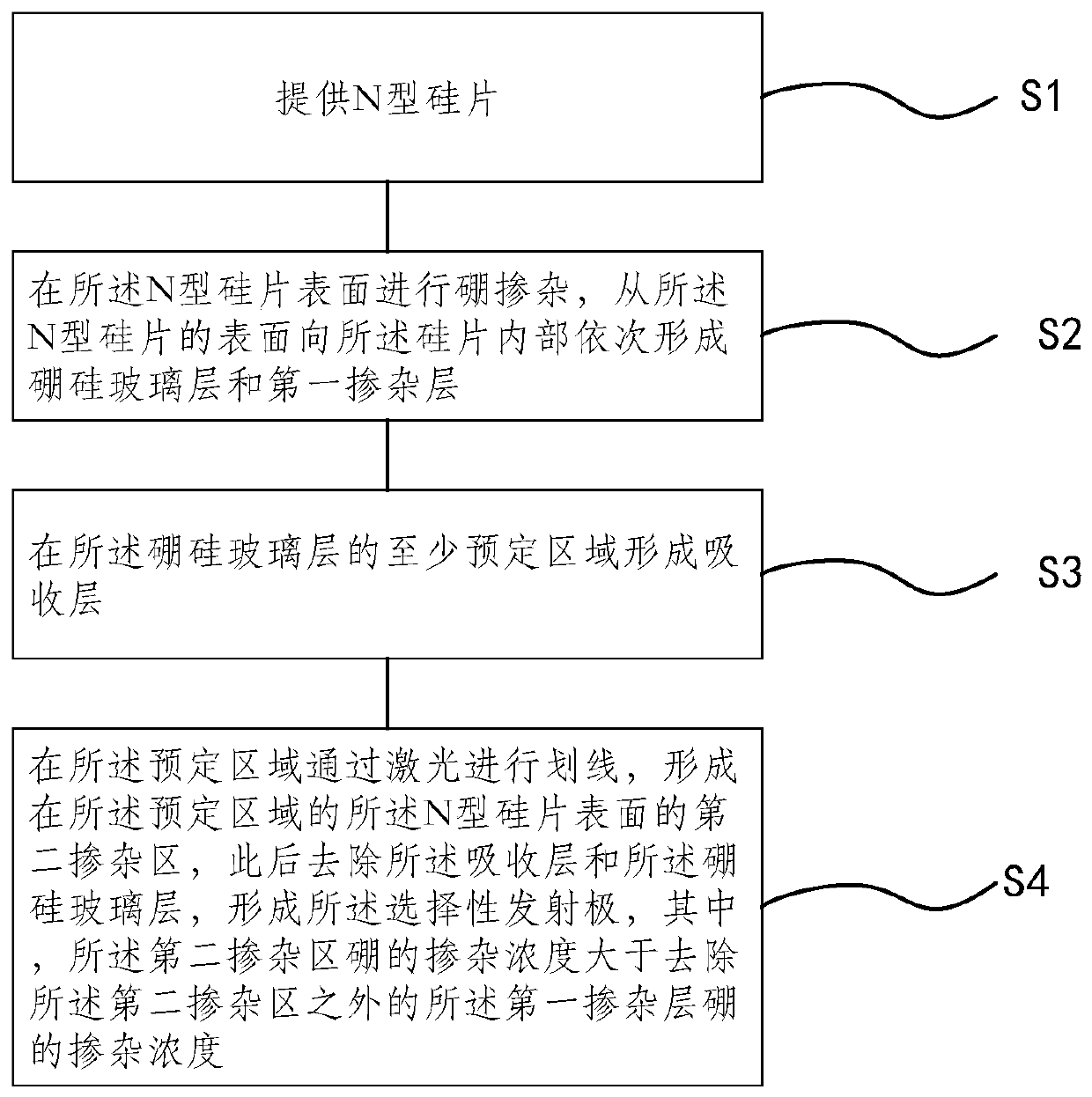

[0038] The preparation method of the N-type battery selective emitter according to the optional embodiment of the present invention, such as figure 1 shown, including the following steps:

[0039] In step S1, an N-type silicon wafer 1 is provided.

[0040] The so-called N-type silicon wafer is doped on the silicon substrate, such as the N-type silicon wafer formed by phosphorus atoms. The ability of impurities in N-type silicon wafers to capture minority carrier holes is lower than that of impurities in P-type silicon wafers to capture minority carrier electrons. The minority carrier lifetime of N-type silicon wafers with the same resistivity is 1 higher than that of P-type silicon wafers. ~2 orders of magnitude, reaching the millisecond level, and the surface recombination rate of minority carrier holes in N-type materials is lower than that of electrons in P-type materials, so N-type silicon wafers can be used to prepare cells with higher photoelectric conversion efficiency...

Embodiment 1

[0065] S11 provides N-type monocrystalline silicon wafers, the thickness of which is 150 microns, and the resistivity is 1 ohm*cm.

[0066] S12, cleaning and chemically etching the N-type silicon wafer 1 to form a textured structure.

[0067] S21, placing the N-type silicon wafer 1 in a diffusion furnace.

[0068] S22, heating up to a diffusion temperature of 960°C.

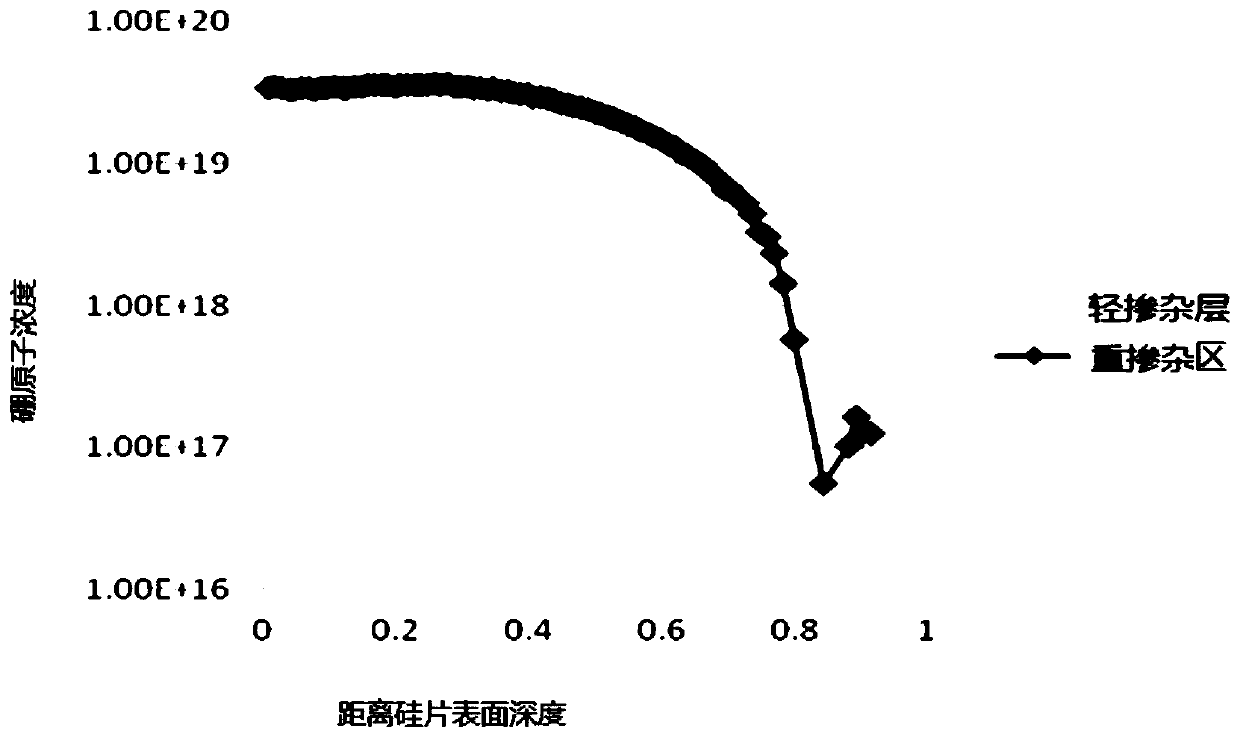

[0069] S23, pass nitrogen gas, oxygen gas (2000 sccm), and boron source nitrogen gas in the diffusion furnace, and diffuse for 40 minutes to form the first doped layer (lightly doped layer) 2 and borosilicate with a square resistance of 120 ohms / □ Glass layer 3.

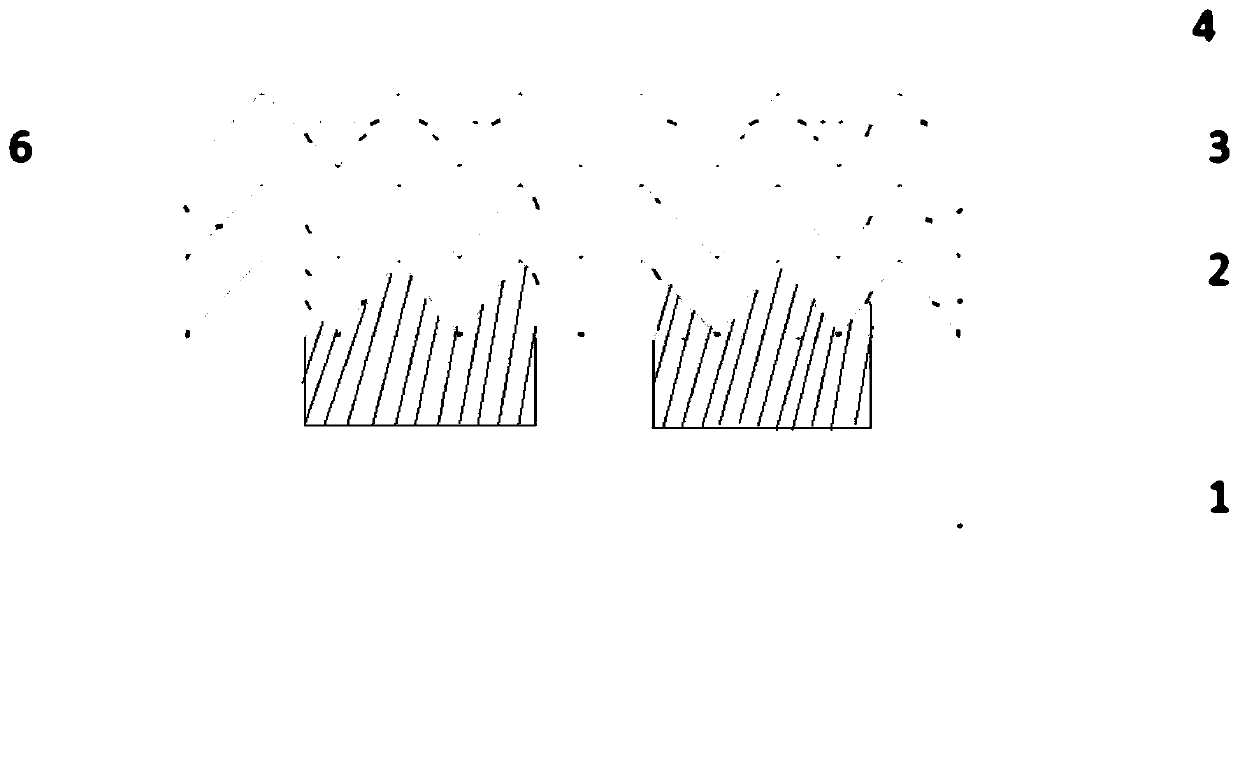

[0070] S31, forming a silicon nitride layer on the surface of the borosilicate glass layer 3 by plasma chemical vapor deposition. The silicon nitride layer is the absorbing layer 4 with a thickness of 75 nm and a refractive index of 2.2.

[0071] S41, scribing lines on the surface of the absorbing layer 4 with a laser, the wavelength of the laser is ...

Embodiment 2

[0075] S11', provide N-type single crystal silicon wafer, the thickness of the silicon wafer is 200 microns, and the resistivity is 3 ohm*cm.

[0076] S12', cleaning and chemically etching the N-type silicon wafer 1 to form a textured structure.

[0077] S21', using atmospheric pressure chemical vapor deposition on the N-type silicon wafer 1 to form the above-mentioned doping source layer and covering layer to form boron oxide (doping source layer) and silicon oxide layer (covering layer) sequentially, wherein the oxide The thickness of the boron layer was 50 nm, the atomic ratio of boron was 3%, and the thickness of the silicon oxide film was 40 nm.

[0078] S22' Put the N-type silicon wafer 1 into a nitrogen atmosphere for annealing, wherein the annealing temperature is 970 degrees, and the time is 50 minutes to form the first doped layer (lightly doped layer) 2 and borosilicate glass layer 3 .

[0079] S31', on the surface of the borosilicate glass layer 3, a silicon oxyn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com