High-pressure discharge lamp

A technology of high-pressure discharge lamps and tungsten electrodes, applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problem of reducing the contact area between the cut surface of molybdenum sheet and quartz glass, affecting the fusion state of quartz glass, and not solving the problem Molybdenum sheet cutting surface and other problems to achieve the effect of eliminating multi-boundary phenomenon, inhibiting peeling phenomenon, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, those of ordinary skill in the art do not say that all other embodiments obtained on the premise of not paying creative efforts belong to the protection scope of the present invention.

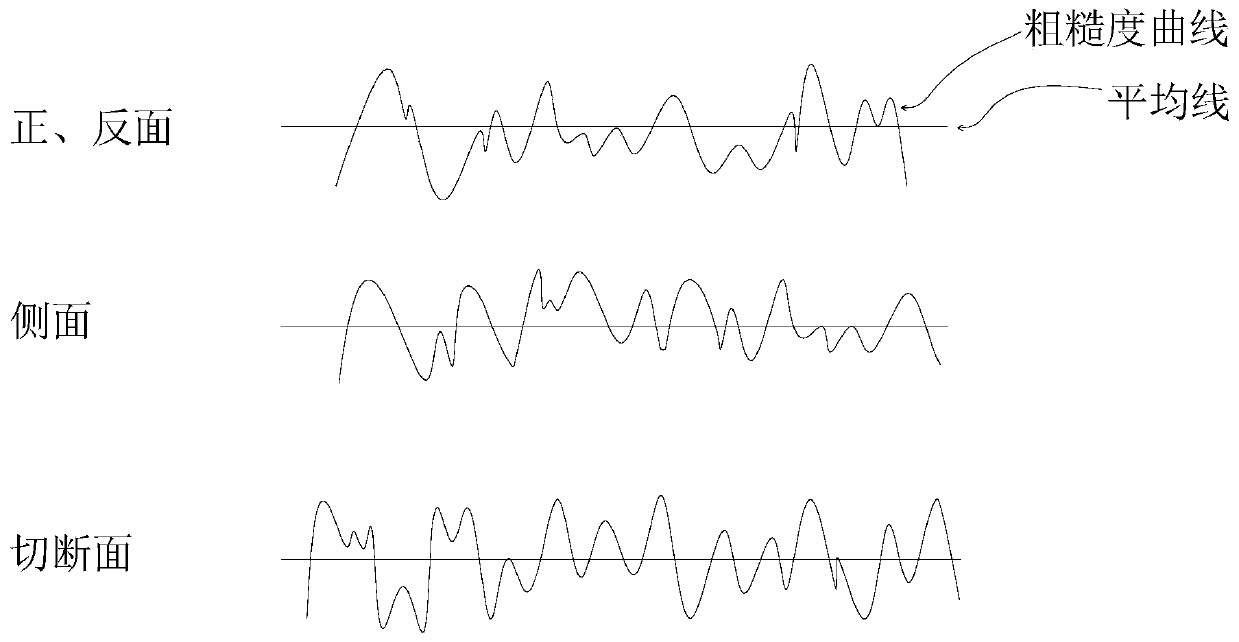

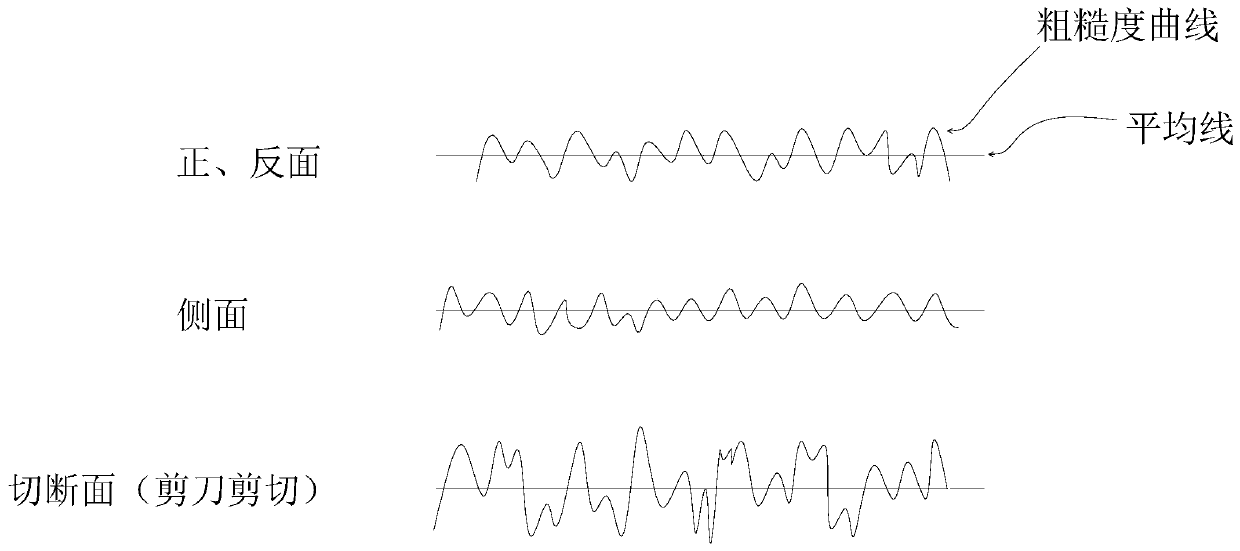

[0028]A high-pressure discharge lamp, the structure of which includes: two tungsten electrodes (2) are arranged oppositely in a quartz container (1), and one end of the tungsten electrode (2) is buried in a side tube (11), and is connected with the quartz The molybdenum sheet or molybdenum alloy sheet (3) (hereinafter referred to as molybdenum sheet) with close expansion coefficient and the external power wire (hereinafter referred to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com