System and method for improving production stability of cut tobacco dryer

A technology of stability and drying machine, applied in general control system, tobacco, tobacco preparation, etc., can solve the problem of distortion of data results, achieve the effect of improving quality, avoiding control differences, and improving quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

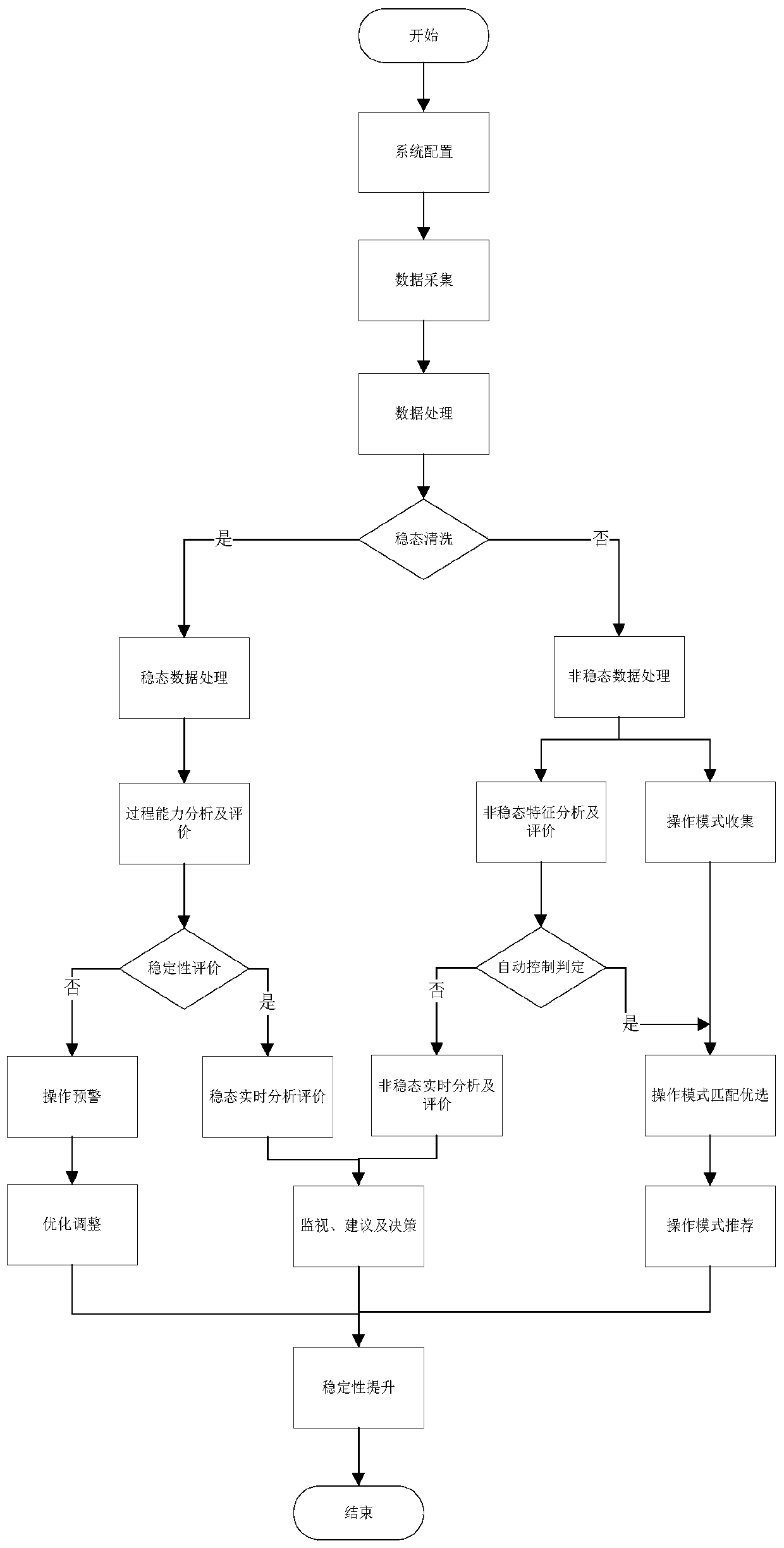

[0041] The present invention will be further described in detail below in conjunction with the examples.

[0042] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The materials or equipment used are not indicated by the manufacturer, and they are all conventional products that can be obtained through purchase.

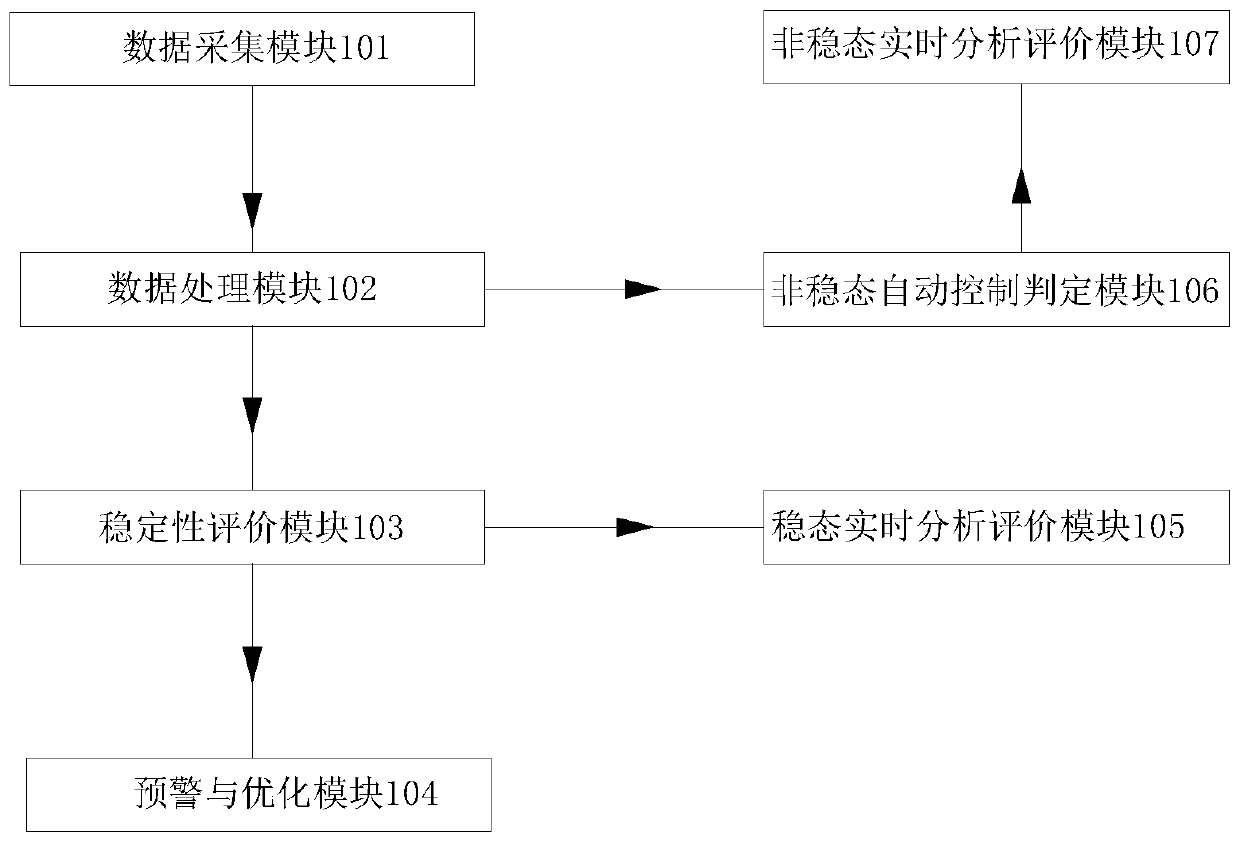

[0043] A system for improving the production stability of a tobacco shred dryer, comprising:

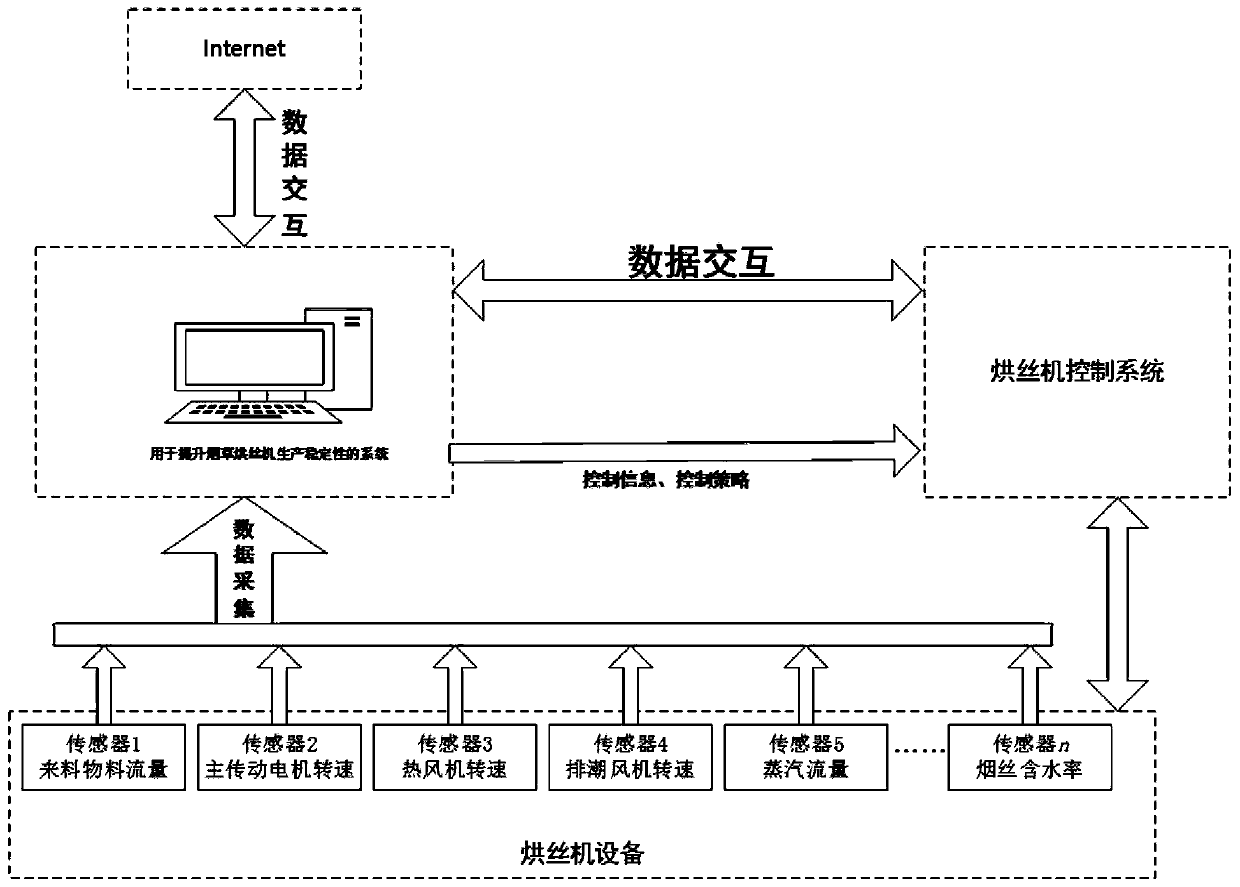

[0044] The data acquisition module 101 is used to obtain real-time data in the production process of the silk dryer through sensors from the silk dryer control system;

[0045]The data processing module 102 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com