A detection method for early fatigue cracks of 316l stainless steel based on critical refraction longitudinal wave and vibration-acoustic modulation technology

A technology of vibration sound modulation and critical refraction, which is applied in the generation of ultrasonic/sonic/infrasonic waves, the use of sound waves/ultrasonic/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic/infrasonic waves for material analysis, etc., to improve the accuracy of detection and positioning , to avoid the effect of multiple reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

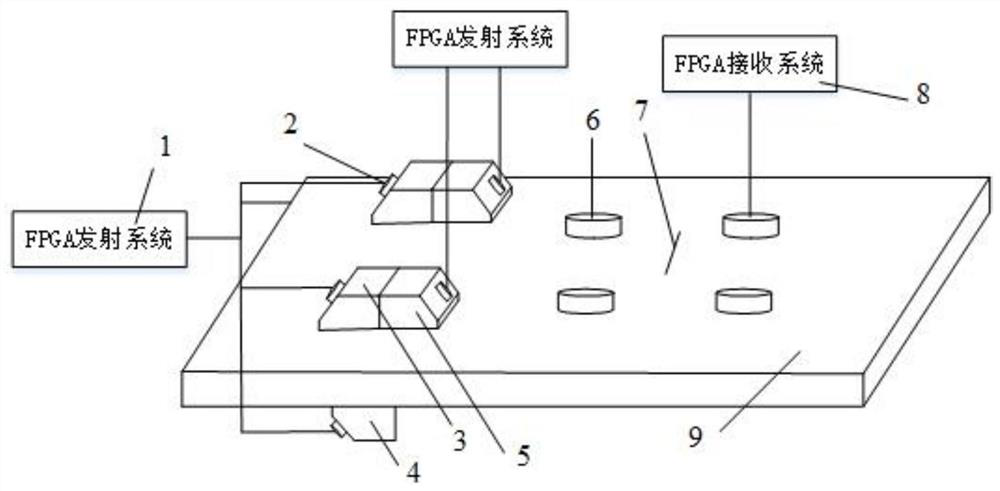

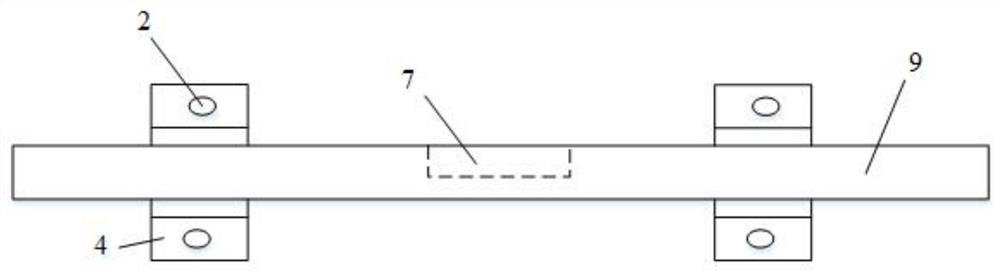

[0018] The present invention will be further described below in conjunction with the accompanying drawings. in figure 1 A three-dimensional map of the entire device; figure 2 for side view.

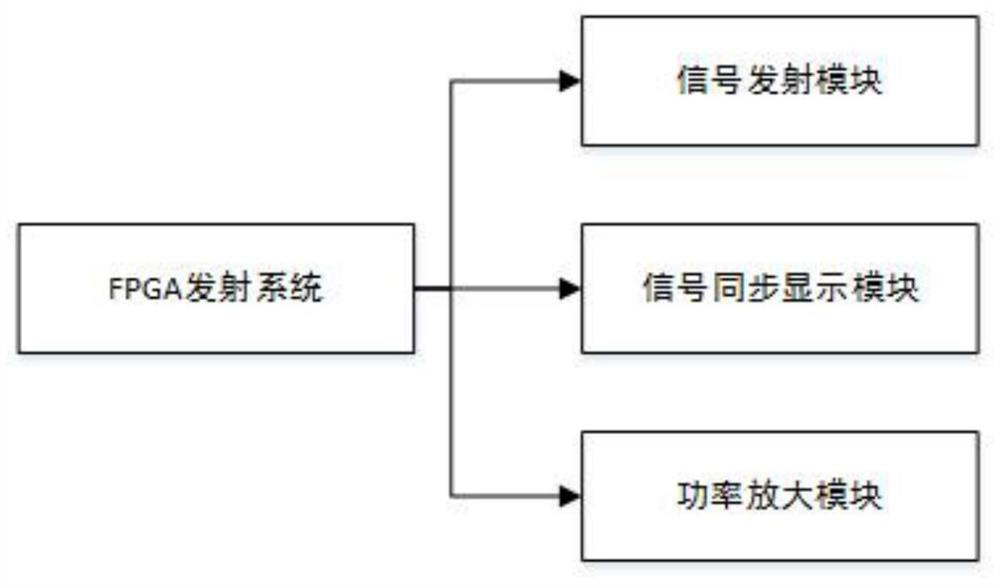

[0019] Such as figure 1 As shown, the device includes FPGA transmitting system 1, transmitting transducer 2, plexiglass wedge 3, plexiglass wedge 4, plexiglass wedge 5, receiving transducer 6, early fatigue crack 7, FPGA receiving system 8 , 316L stainless steel components 9. Among them, the FPGA launch system 1 such as image 3 Including: signal transmitting module, signal synchronous display module, power amplification module; plexiglass wedges 3 and 4 whose angles are designed as image 3 As shown, its incident angle is equal to the first critical angle , which is used to eliminate the reflected wave in the wedge; the angle design of the plexiglass wedge 5 is as follows Figure 5 As shown, the incident angle is equal to the refraction angle of the refracted shear wave, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com