Full biodegrade copolyester fibers and preparation method thereof

A copolyester and all-biological technology, applied in the direction of single-component copolyester artificial filaments, etc., can solve problems such as insufficient esterification rate, inability to meet spinning processing requirements, and low molecular weight of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

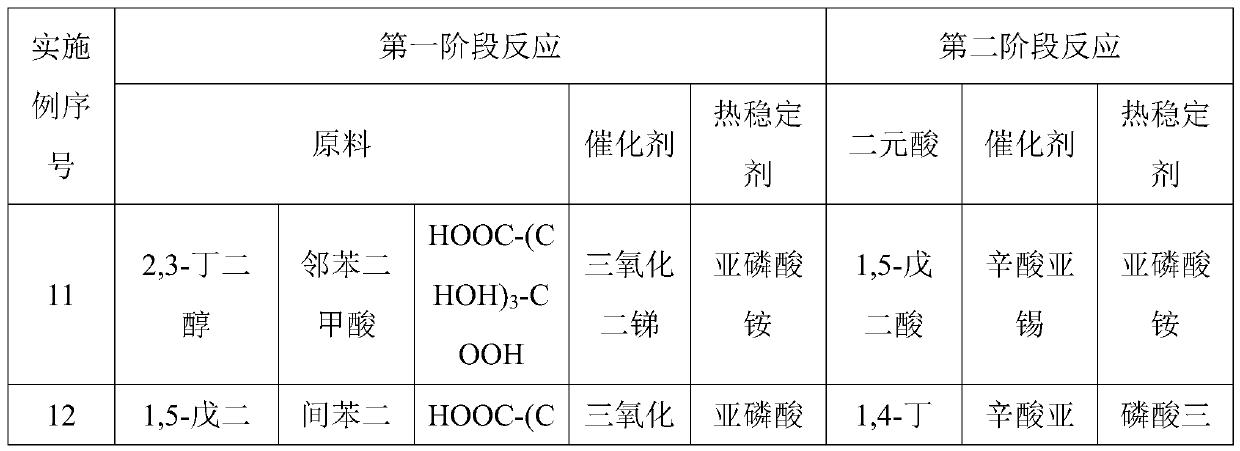

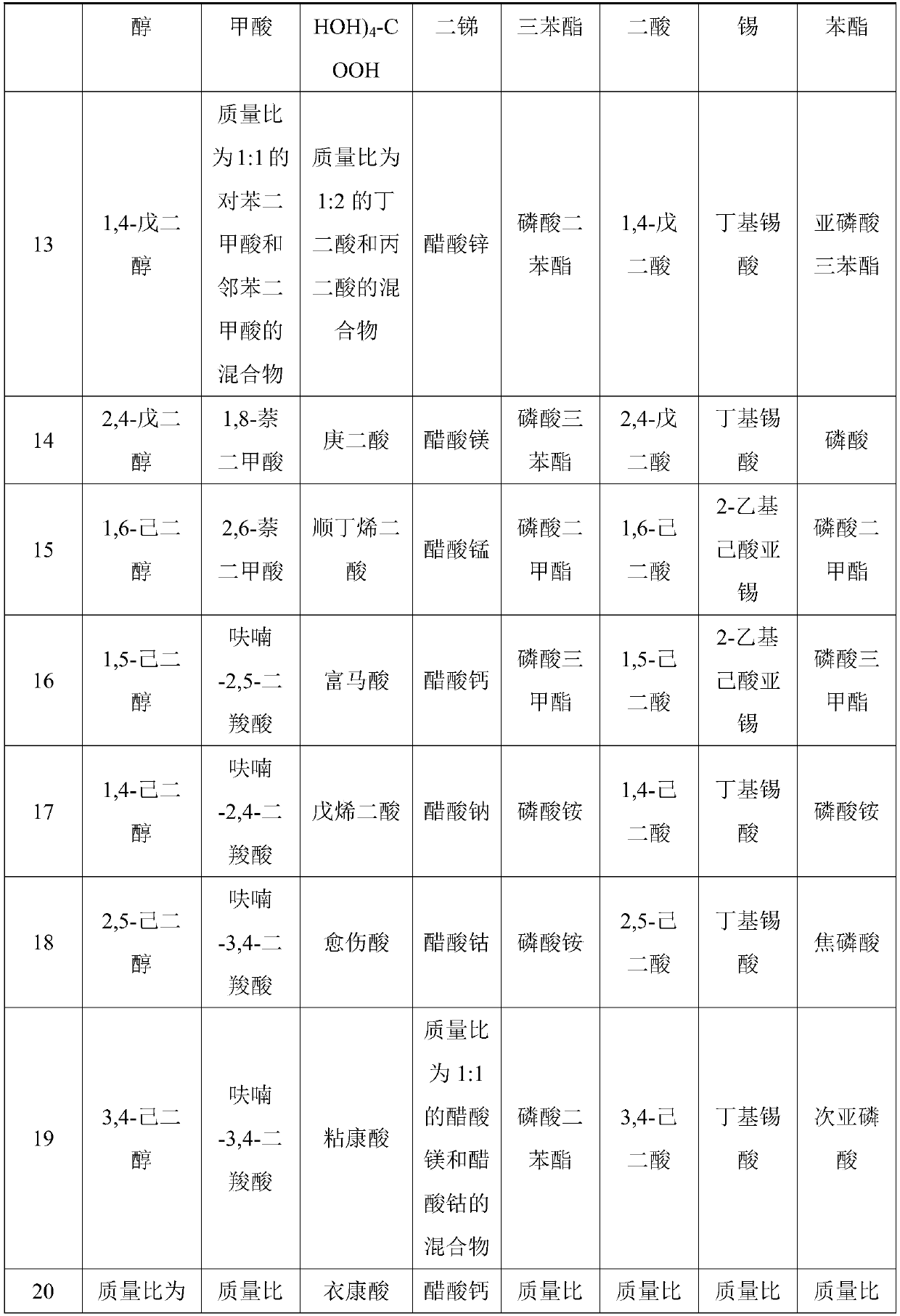

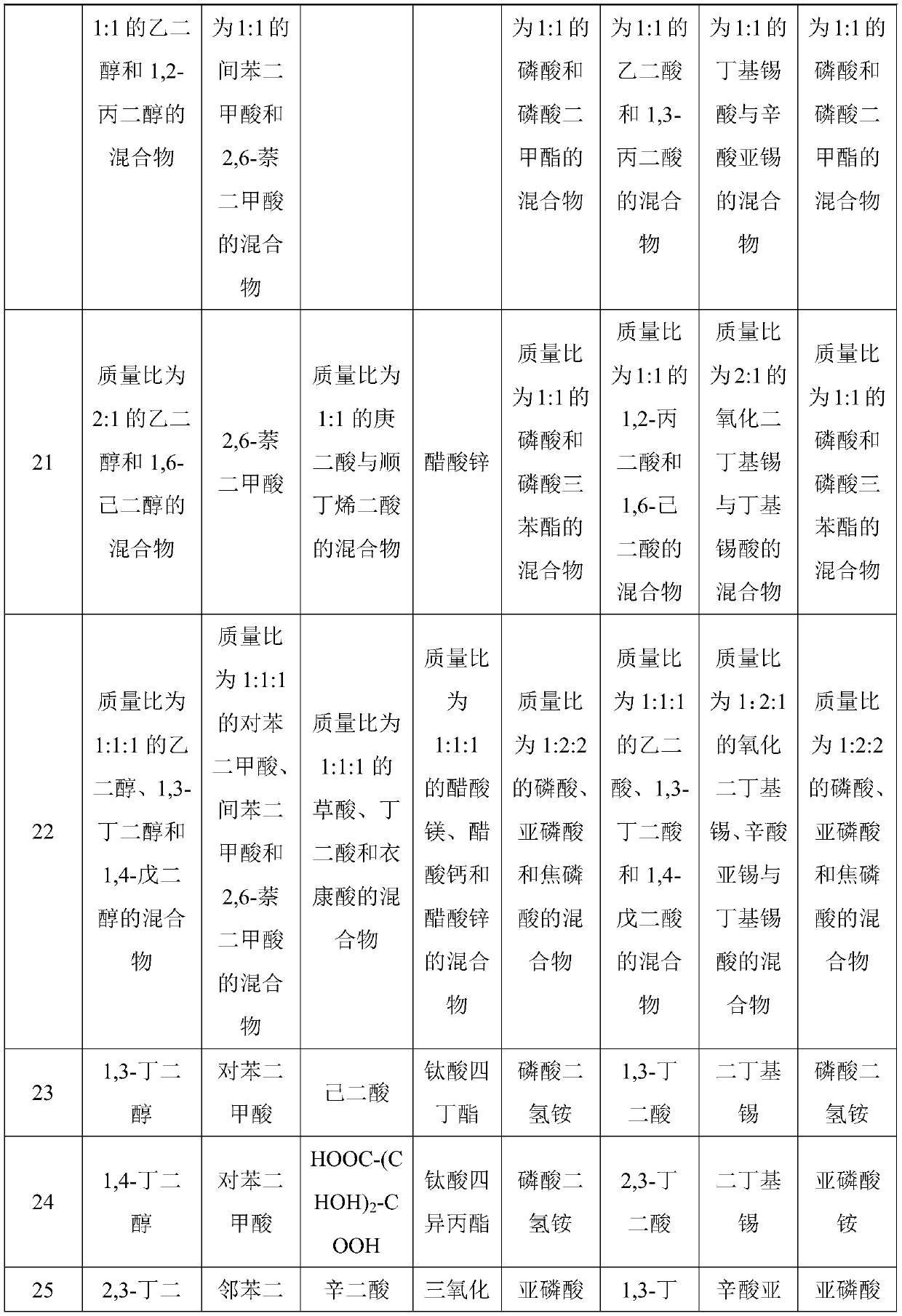

Examples

Embodiment 1

[0044] A preparation method of fully biodegradable copolyester fibers, the steps are as follows:

[0045] (1) The first stage reaction: using 1,4-butanediol, terephthalic acid and adipic acid as raw materials, adding phosphoric acid and antioxidant 1010 at the same time, under the temperature of 190°C and under the action of tetrabutyl titanate Esterification for 2 hours, followed by prepolymerization for 0.5 hours at a pressure of 0.05 mbar and a temperature of 200° C., wherein the ratio of the molar weight of 1,4-butanediol to the sum of the molar weights of terephthalic acid and adipic acid is 1.1: 1. The ratio of the molar weight of tetrabutyl titanate to the sum of the molar weights of terephthalic acid and adipic acid is 50ppm, and the addition amounts of phosphoric acid and antioxidant 1010 are 1,4-butanediol and terephthalic acid respectively 0.1% and 0.2% of the sum of mass of adipic acid;

[0046] (2) Second-stage reaction: take the first-stage product, IIDML and adip...

Embodiment 2

[0062] A preparation method of fully biodegradable copolyester fibers, the steps are as follows:

[0063] (1) The first stage reaction: using 1,4-butanediol, terephthalic acid and adipic acid as raw materials, adding phosphoric acid and antioxidant 1010 at the same time, under the temperature of 210°C and under the action of tetrabutyl titanate Esterification for 2 hours, followed by prepolymerization for 0.5 hours at a pressure of 0.05 mbar and a temperature of 230° C., wherein the ratio of the molar weight of 1,4-butanediol to the sum of the molar weights of terephthalic acid and adipic acid is 1.5: 1. The ratio of the molar weight of tetrabutyl titanate to the sum of the molar weights of terephthalic acid and adipic acid is 2000ppm, and the addition amounts of phosphoric acid and antioxidant 1010 are 1,4-butanediol and terephthalic acid respectively 0.1% and 0.2% of the sum of mass of adipic acid;

[0064] (2) The second-stage reaction: using the first-stage product, IIDML...

Embodiment 3

[0071] A preparation method of fully biodegradable copolyester fibers is basically the same as in Example 2, except that 2,4-pentanediol is added in step (2) instead of 1,4-butanediol, The molar amount of IIDML in step (2) accounts for 50% of the sum of the molar amounts of 2,4-pentanediol in step (2) and IIDML in step (2).

[0072] The intrinsic viscosity of the fully biodegradable copolyester that finally makes is 0.60dL / g, and the number-average molecular weight is 16,800g / mol, and the molar weight of IIDML accounts for the 1,4-butanediol, 4-butanediol, 2 in the step (2), the ratio of the molar weight sum of 4-pentanediol and IIDML accounts for the 1,4-butanediol in the step (1), the 2 in the step (2) when the molar weight of IIDML accounts for the proportion ratio of feeding. , the ratio of the sum of the moles of 4-pentanediol and IIDML is lower than 0%;

[0073](4) Melt-spinning the fully biodegradable copolyester prepared in step (3) to obtain fully biodegradable copol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com