High-refractive-index alkaline water soluble resin and preparation method thereof, and high-refractive-index photoresist

A high-refractive-index, soluble technology, applied in the photoengraving process of the pattern surface, photosensitive materials for opto-mechanical equipment, optics, etc., can solve the problem of large under-cut, low refractive index of photoresist, and insufficient curing of the bottom layer. and other problems, to achieve the effect of improving resolution, good light transmission, and improving deep curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

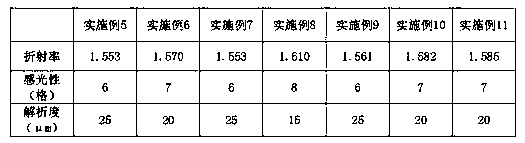

Examples

Embodiment 1

[0035] In the reactor, add 39 parts of solvent propylene glycol methyl ether acetate, 49 parts of o-phenylphenoxyethyl acrylate, 12 parts of acrylic acid and 0.6 part of azobisisobutylcyanide,

[0036] Under the protection of nitrogen, the temperature was raised to 90°C, and the polymerization reaction was carried out. The reaction was completed in 6 hours, and an alkali-water-soluble resin with a high refractive index was obtained;

[0037] Its weight-average molecular weight is 80,000 (Mw), its molecular weight distribution index is 2.05, its acid value is 100 mg KOH / g, and its dry resin has a refractive index of 1.568.

Embodiment 2

[0039] Add 50 parts of solvent propylene glycol methyl ether acetate, 40 parts of phenoxybenzyl acrylate, 10 parts of acrylic acid and 0.5 part of azobisisobutyronitrile into the reaction kettle, and raise the temperature to 90°C under the protection of nitrogen to carry out the polymerization reaction, reaction 7 At the end of the hour, an alkali-water-soluble resin with a high refractive index is obtained;

[0040] Its weight-average molecular weight is 55,000 (Mw), its molecular weight distribution index is 1.98, its acid value is 78 mg KOH / g, and its dry resin has a refractive index of 1.558.

Embodiment 3

[0042] Add 39 parts of solvent dipropylene glycol monomethyl ether, 55 parts of biphenylmethanol acrylate, 6 parts of acrylic acid and 0.4 part of azobisisobutyrocyanide into the reaction kettle, and raise the temperature to 80°C under the protection of nitrogen to carry out the polymerization reaction. Reaction 4 At the end of the hour, an alkali-water-soluble resin with a high refractive index is obtained;

[0043] Its weight-average molecular weight is 100,000 (Mw), its molecular weight distribution index is 2.13, its acid value is 50 mg KOH / g, and its dry resin has a refractive index of 1.600.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com