Fireproof door core plate formed through rapid autoclaved curing and preparation method thereof

A fire door core board, autoclave curing technology, applied in the field of fire door materials, can solve the problems of long natural curing time, large maintenance area, low production efficiency, etc., and achieve excellent anti-carbonation performance, low mass loss rate, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

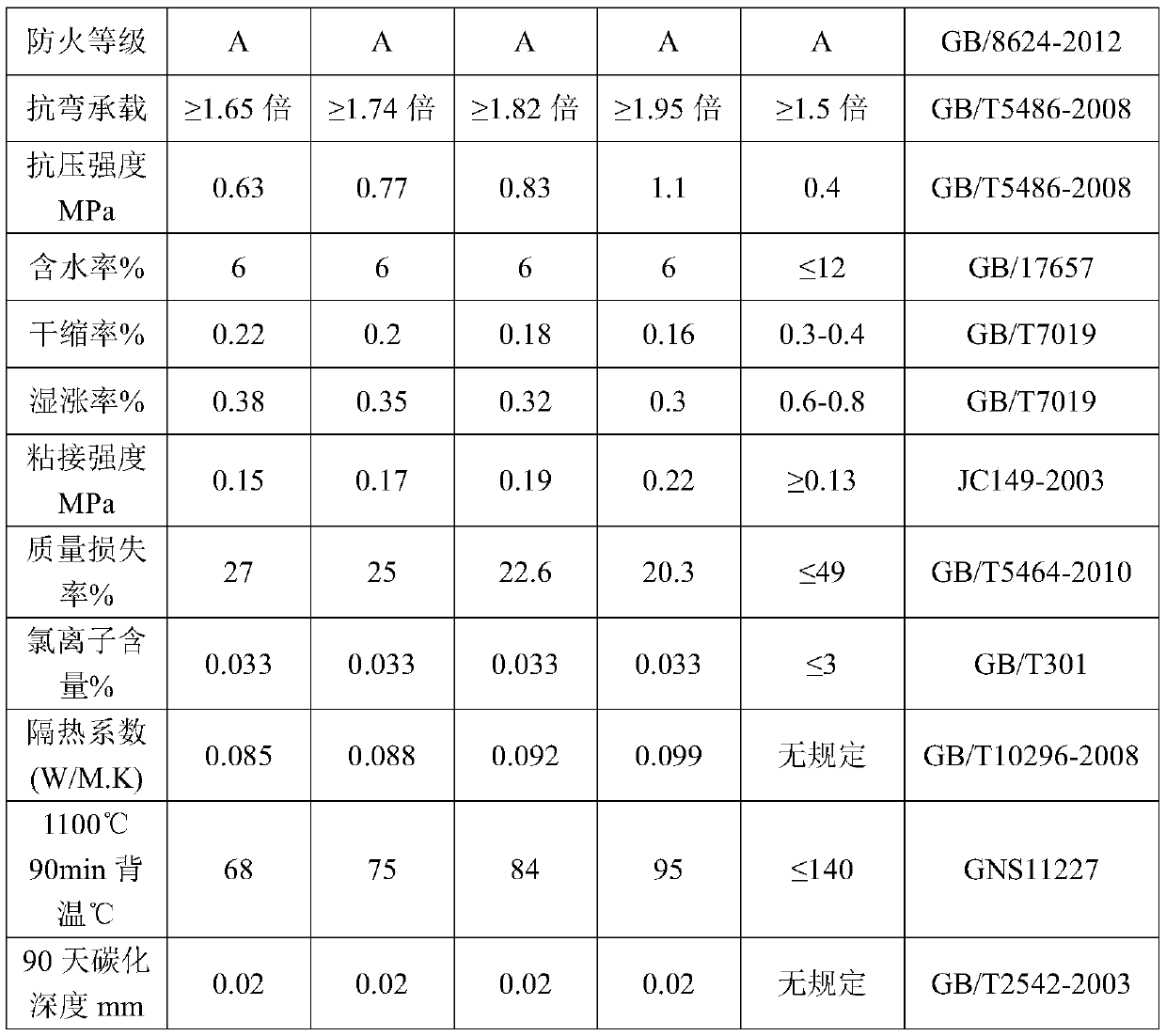

Embodiment 1

[0046] A kind of preparation of fire door core board formed by rapid autoclaving curing:

[0047] 1) Preparation of cement admixture: Start the reactor with heating and stirring, take 27kg of water, 2kg of anionic fatty alcohol polyoxyethylene ether, 20kg of nano-silica sol and 15kg of long-chain polymer carboxylic acid acrylic acid polymer and put them into the reactor for mixing, heat Fully react at 98°C for 3.5 hours, after the reaction, cool down to 65°C, add 30kg of naphthalene-based high-efficiency water reducer dropwise, control the dropwise addition within 45 minutes, then cool down to 40°C, add 5kg of sodium benzoate and 1kg of calorie Loosen to the reaction kettle, continue to stir for 30 minutes to fully react, and prepare cement admixture for future use;

[0048] 2) Preparation of water-based composite foaming agent: start the heating belt stirring reactor, take 45kg of water, 7kg of long-chain fatty alcohol polyoxyethylene ether, 25kg of sulfonate surfactants and ...

Embodiment 2

[0054] A kind of preparation of fire door core board formed by rapid autoclaving curing:

[0055] 1) Preparation of cement admixture: start the heating belt stirring reactor, take 19kg of water, 2kg of anionic fatty alcohol polyoxyethylene ether, 25kg of nano-silica sol and 15kg of long-chain polymer carboxylic acid acrylic acid polymer into the reactor for mixing, heat Fully react at 98°C for 3.5 hours, after the reaction, cool down to 65°C, add 30kg polycarboxylate superplasticizer dropwise, control the dropwise addition within 45 minutes, then cool down to 40°C, add 5kg sodium benzoate and 1kg Cassone to the reactor, continue to stir for 30 minutes to fully react, and prepare the cement admixture for subsequent use;

[0056] 2) Preparation of water-based composite foaming agent: start the heating belt stirring reactor, take 40kg of water, 12kg of long-chain fatty alcohol polyoxyethylene ether, 25kg of sulfonate surfactants and 8kg of saturated fatty acids containing 16 carb...

Embodiment 3

[0062] A kind of preparation of fire door core board formed by rapid autoclaving curing:

[0063] 1) Preparation of cement admixture: Start the reactor with heating and stirring, take 9kg of water, 2kg of anionic fatty alcohol polyoxyethylene ether, 30kg of nano-silica sol and 20kg of long-chain polymer carboxylic acid acrylic acid polymer and put them into the reactor for mixing, heat Fully react at 98°C for 3.5 hours, after the reaction, cool down to 65°C, add 30kg of naphthalene-based high-efficiency water reducer dropwise, control the dropwise addition within 45 minutes, then cool down to 40°C, add 8kg of sodium benzoate and 1kg of calorie Loosen to the reaction kettle, continue to stir for 30 minutes to fully react, and prepare cement admixture for future use;

[0064] 2) Preparation of water-based composite foaming agent: start the heating belt stirring reactor, take 40kg of water, 16kg of long-chain fatty alcohol polyoxyethylene ether, 16kg of sulfonate surfactants and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com