Solid wood fire door manufacturing method and solid wood fire door

A manufacturing method and technology for fire doors, which are applied in the field of fire doors, can solve the problems of unsatisfactory immersion depth, difficulty in immersion of pretreatment liquid, high processing time and cost, and achieve poor local fire protection effect and uniform distribution of flame retardant effect , good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

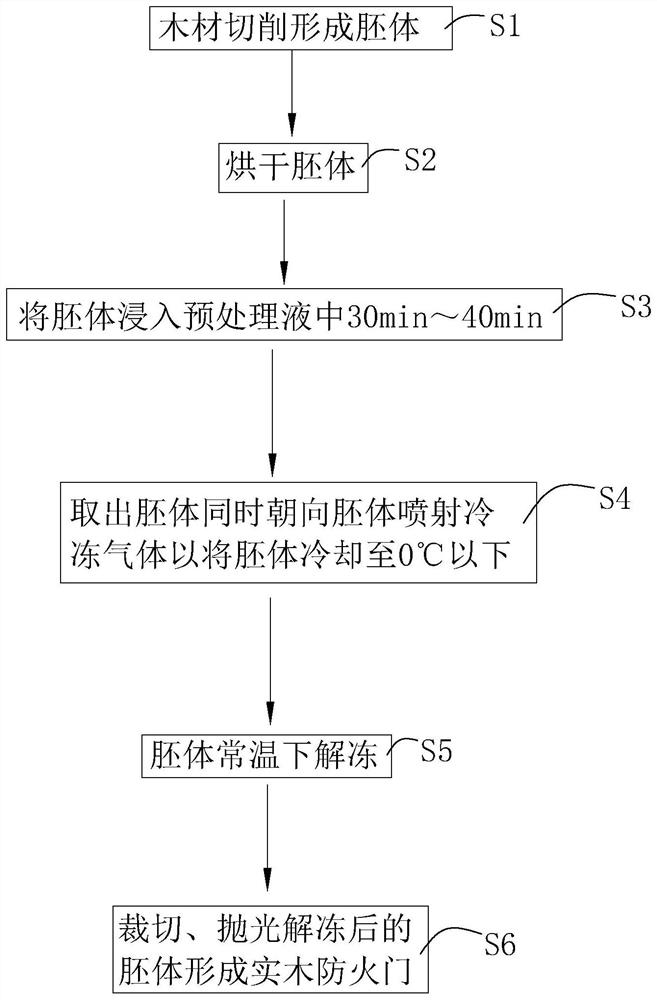

[0058] refer to figure 1 , is a kind of solid wood fireproof door manufacturing method disclosed by the present invention, and concrete steps are as follows:

[0059] S1. Cut the solid wood according to the requirements of the design drawings to obtain the embryo body. The length, width and height of the embryo body are 110% of the length, width and height in the design drawings, and the embryo body does not need to be polished.

[0060] S2. Put the embryo body into an oven, control the temperature in the oven to 110° C., and bake for 40 minutes to dry the embryo body.

[0061] S3. Add 2 tons of pretreatment liquid into a water tank with a length of 3m, a width of 3m, and a depth of 1m, heat the pretreatment liquid to 80°C, put a water pump in the water tank, and start the water pump to keep the pretreatment liquid in the water tank in circulation at all times Put the dried embryo body into the water tank and soak for 40 minutes, and press the embryo body with a heavy object ...

Embodiment 2

[0069] refer to figure 1 , is a kind of solid wood fireproof door manufacturing method disclosed by the present invention, and concrete steps are as follows:

[0070] S1. Cut the solid wood according to the requirements of the design drawings to obtain the embryo body. The length, width and height of the embryo body are 110% of the length, width and height in the design drawings, and the embryo body does not need to be polished.

[0071] S2. Put the embryo body into an oven, control the temperature in the oven to 115° C., and bake for 35 minutes to dry the embryo body.

[0072] S3. Add 2 tons of pretreatment liquid into a water tank with a length of 3m, a width of 3m, and a depth of 1m, heat the pretreatment liquid to 82.5°C, put a water pump in the water tank, and start the water pump to keep the pretreatment liquid in the water tank in circulation at all times Put the dried embryo body into the water tank and soak for 35 minutes, and press the embryo body with a heavy objec...

Embodiment 3

[0079] refer to figure 1 , is a kind of solid wood fireproof door manufacturing method disclosed by the present invention, and concrete steps are as follows:

[0080] S1. Cut the solid wood according to the requirements of the design drawings to obtain the embryo body. The length, width and height of the embryo body are 110% of the length, width and height in the design drawings, and the embryo body does not need to be polished.

[0081] S2. Put the embryo body into an oven, control the temperature in the oven to 120° C., and bake for 30 minutes to dry the embryo body.

[0082] S3. Add 2 tons of pretreatment liquid into a water tank with a length of 3m, a width of 3m, and a depth of 1m, heat the pretreatment liquid to 85°C, put a water pump in the water tank, and start the water pump to keep the pretreatment liquid in the water tank in circulation at all times Put the dried embryo body into the water tank and soak for 30 minutes, and press the embryo body with a heavy object ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com