Preparation and application of Pd/TiO2 hydrogen evolution catalyst

A catalyst and hydrogen evolution technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of restricting the development of hydrogen production by electrolysis of water and expensive catalysts, etc. Achieve good catalytic activity, good crystallinity and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

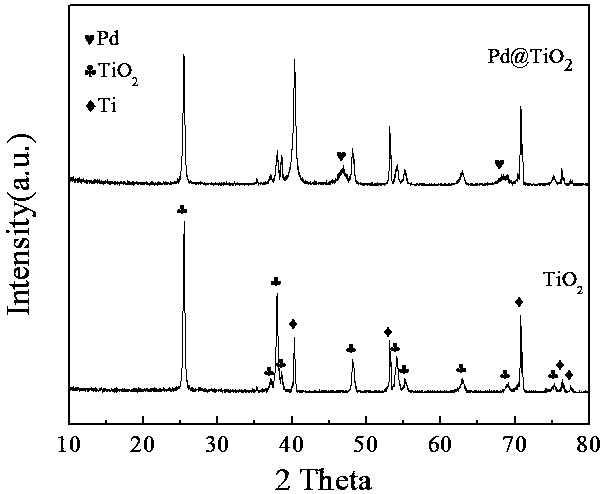

[0026] Pd / TiO of Example 1 2 The preparation and application of hydrogen evolution catalyst includes the following steps:

[0027] 1) Cut the 1mm thick titanium sheet into a size of 10mm*15mm and place them in acetone (CH 3 COCH 3 ), ethanol (C 2 H 6 O) and water (H 2 O) Ultrasound for 10 minutes in each medium, and dry in the air;

[0028] 2) The dried titanium sheet was polished in the polishing solution for 30 seconds and then quickly cleaned with water. After cleaning, it was dried in an oven at 60°C for 10 hours. The polishing solution was made of nitric acid (HNO 3 ): Hydrofluoric acid (HF): Water (H 2 O)=4:1:5 (V:V:V) composition;

[0029] 3) In 0.5wt% ammonium fluoride (NH 4 F) ethylene glycol (C 2 H 6 O 2 ) In the electrolyte of +3vol% water, react for 2h at a voltage of 50V. After the reaction is completed, TiO is obtained 2 Nanotubes, washed and dried, annealed at 500℃ for 2h; 4) In 1mM palladium chloride (PdCl 2 ) And 0.1M sodium chloride (NaCl) in the electrolyte, at 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com