Rubber canvas gumming formula, preparation method thereof and preparation method of rubber canvas

A canvas and rubber technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems that the glue cannot be combined with two layers of canvas, and the performance decline, etc., to achieve the effect of not easy interface damage, low cost, and excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

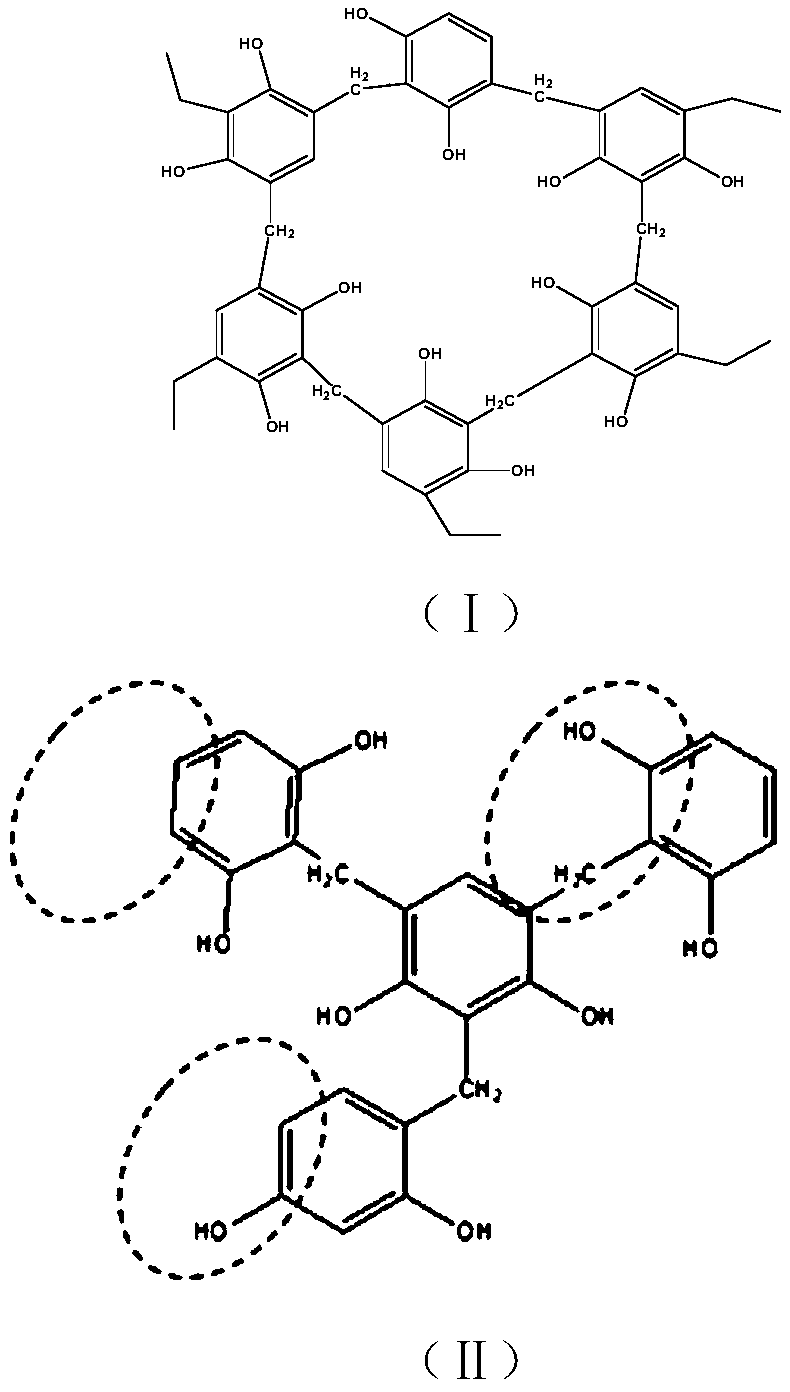

Method used

Image

Examples

Embodiment 1

[0034] A kind of rubber canvas dipping formula and the preparation method of rubber canvas, concrete steps are as follows:

[0035] (1) water and sodium hydroxide are mixed;

[0036] (2) Adding resorcinol and formaldehyde to the system of (1), stirring and reacting for 2 hours at a temperature of 22° C.;

[0037] (3) latex, ammoniacal liquor and water are mixed;

[0038] (4) Mix the system of (2) and the system of (3), first stir for 30 minutes, and then stand and react for 18 hours at a temperature of 18°C;

[0039] (5) Add blocked isocyanate to the system of (4), and stir for 30 minutes.

[0040] Through steps (1) to (5), the rubber canvas dipping formula is obtained, wherein, by weight percentage, resorcinol and formaldehyde account for 2%, ammonia water accounts for 0.2%, sodium hydroxide accounts for 0.02%, and latex accounts for 40%. %, blocked isocyanate accounts for 0.5%, and the balance of water, wherein the molar ratio of resorcinol to formaldehyde is 1:0.7;

[0...

Embodiment 2

[0046] A kind of rubber canvas dipping formula and the preparation method of rubber canvas, concrete steps are as follows:

[0047] (1) water and sodium hydroxide are mixed;

[0048] (2) Adding resorcinol and formaldehyde to the system of (1), stirring and reacting for 3 hours at a temperature of 23° C.;

[0049] (3) latex, ammoniacal liquor and water are mixed;

[0050] (4) Mix the system of (2) and the system of (3), first stir for 30 minutes, and then stand and react for 20 hours at a temperature of 19°C;

[0051] (5) Add blocked isocyanate to the system of (4), and stir for 30 minutes.

[0052] Through steps (1) to (5), the rubber canvas dipping formula is obtained, wherein, by weight percentage, resorcinol and formaldehyde account for 2%, ammonia water accounts for 0.3%, sodium hydroxide accounts for 0.03%, and latex accounts for 35%. %, blocked isocyanate accounts for 0.8%, and the water balance, wherein the molar ratio of resorcinol to formaldehyde is 1:0.8;

[0053...

Embodiment 3

[0055] A kind of rubber canvas dipping formula and the preparation method of rubber canvas, concrete steps are as follows:

[0056] (1) water and sodium hydroxide are mixed;

[0057] (2) Adding resorcinol and formaldehyde to the system of (1), stirring and reacting for 4 hours at a temperature of 24° C.;

[0058] (3) latex, ammoniacal liquor and water are mixed;

[0059] (4) Mix the system of (2) and the system of (3), first stir for 30 minutes, and then stand and react for 22 hours at a temperature of 20°C;

[0060] (5) Add blocked isocyanate to the system of (4), and stir for 30 minutes.

[0061] Through steps (1) to (5), the rubber canvas dipping formula is obtained, wherein, by weight percentage, resorcinol and formaldehyde account for 3%, ammonia water accounts for 0.4%, sodium hydroxide accounts for 0.04%, and latex accounts for 40%. %, blocked isocyanate accounts for 1.2%, and the water balance, wherein the molar ratio of resorcinol to formaldehyde is 1:0.9;

[0062...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com