A kind of waste water treatment method and its application

A waste water treatment and waste water technology, applied in metallurgical waste water treatment, food industry waste water treatment, textile industry waste water treatment and other directions, can solve the problems of substandard discharge, long time for biochemical culture, unstable effluent, etc. The effect of meeting emission standards and reducing operating costs and pre-risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

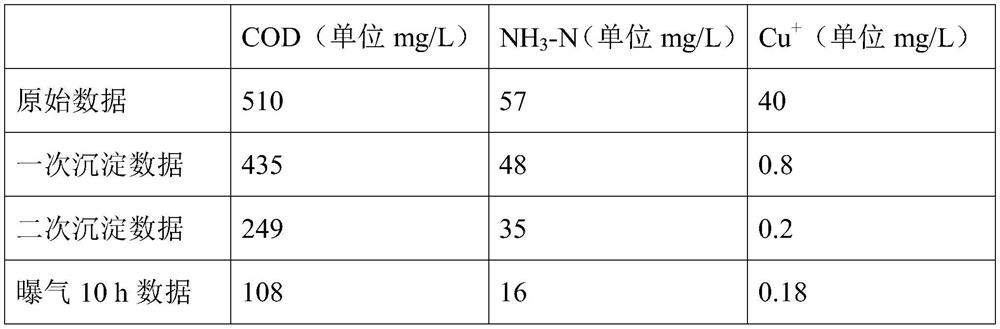

[0036] The present embodiment provides a method for purifying electroplating wastewater, the method comprising the following steps:

[0037] (1) Sampling of electroplating wastewater to detect its COD and NH 3 -N and Cu + content;

[0038] (2) drop into ferrous sulfate wherein, the dosage is 500mg / L, and the pH value of control waste water is 5-6 scope;

[0039] (3) After 20min, add lime (the dosage is 200mg / L), sodium sulfide (the dosage is 150mg / L), PAC / PAM (the dosage is 150mg / L) for a precipitation, and Control the pH value of wastewater to 8-9, and measure its COD and NH after 20 minutes 3 -N and Cu + content;

[0040] (4) Put in PAC / PAM again (the dosage is 100mg / L) for secondary precipitation, and control the pH value of the wastewater to be 8-9, and measure its COD and NH after 20min 3 -N and Cu + content;

[0041] (5) After 10 minutes, put into the meat processing plant sludge (the dosage is 20g / L), carry out aeration, control the oxygen dissolved amount of th...

Embodiment 2

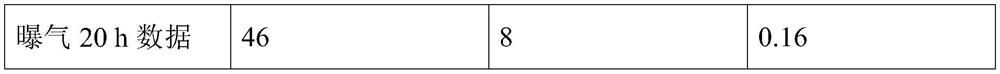

[0046] This embodiment provides a method for purifying electroplating wastewater. The difference between the method and Embodiment 1 is that the pH value of the wastewater is controlled to be 6-7 in step (5), and other conditions remain unchanged. The results are shown in Table 2:

[0047] Table 2

[0048]

[0049]

[0050] It can be seen from the data in Table 2: the wastewater treatment method involved in the present invention is a very important factor in controlling the pH environment of the wastewater during the aeration process. If the pH value is too low, the COD, NH 3 The purifying ability of -N is significantly reduced.

Embodiment 3

[0052] This embodiment provides a method for purifying electroplating wastewater. The difference between the method and Example 1 is that the pH value of the wastewater is controlled to be 8.5-9.0 in step (5), and other conditions remain unchanged. The results are shown in Table 3:

[0053] table 3

[0054] COD (unit mg / L) NH 3 -N (unit mg / L)

[0055] It can be seen from the data in Table 3: the wastewater treatment method involved in the present invention is a very important factor in controlling the pH environment of the wastewater during the aeration process. If the pH value is too high, the COD, NH 3 The purifying ability of -N is significantly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com