A Rubber Forming Method for Thin-walled Reinforced Panel Parts with Multiple Surrounding Deep Rib Structures

A panel and component technology, applied in the field of aircraft manufacturing, can solve the problems of difficult control of forming quality and material deformation, instability and cracking of falling pressure forming, and low forming precision, so as to solve the problem of forming cracking, improve forming accuracy, and reduce manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

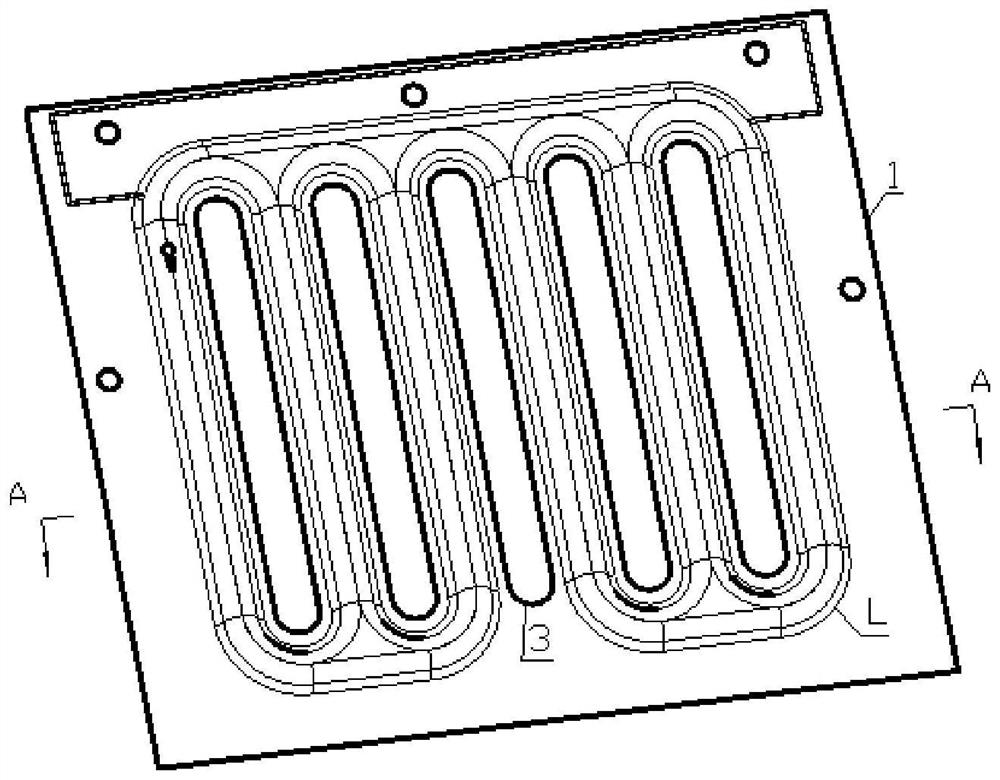

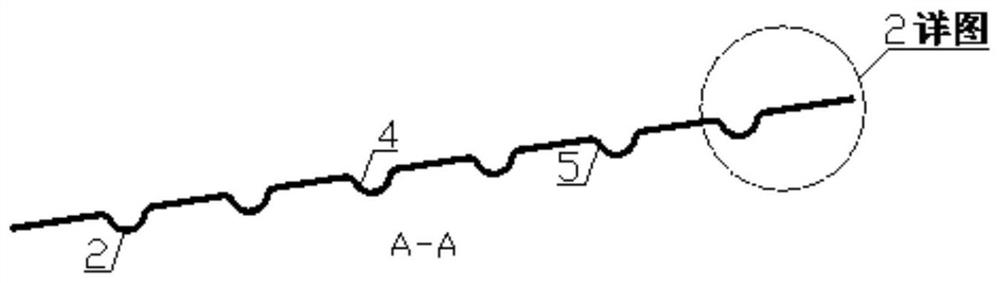

[0040] Referring to the accompanying drawings, the aircraft sheet metal parts provided by the embodiment are as figure 1 As shown, the reinforced panel part 1 is provided with a plurality of surrounding reinforcing ribs 2, and each annular reinforcing rib 2 is provided with a lightening hole 3 corresponding to the outer shape. The aluminum alloy reinforced panel part 1 has a thin wall, and the reinforcing ribs 2 are densely arranged and deep. The disadvantages of traditional drop forming are long processing cycle, large amount of manual correction, serious instability, wrinkling, thinning and cracking, and cracks sometimes occur on the assembly site. The forming quality restricts the normal development of subsequent bonding work.

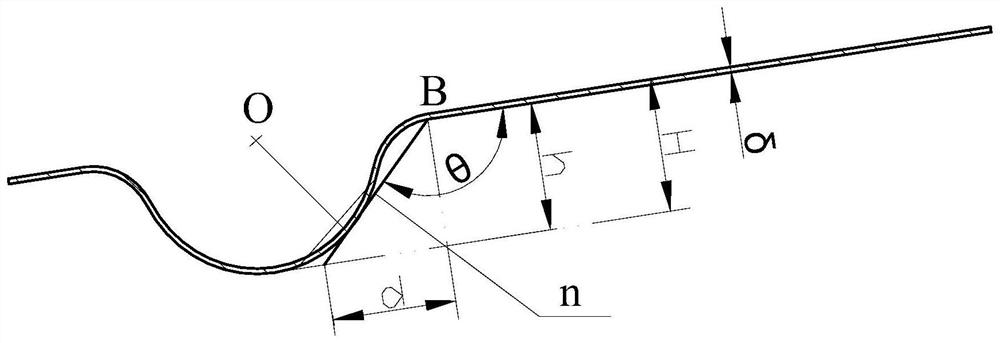

[0041] Such as Figure 2 to Figure 11 As shown, a rubber forming method for thin-walled reinforced panel parts with multiple surrounding deep rib structures includes the following steps:

[0042] Step 1 makes the rubber forming mold of the reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com