Pre-processing system and pre-processing method for heat formation operation

A pre-processing and hot forming technology, applied in the field of metal processing and forming, can solve the problems of reducing the quality of processing, easy heat loss, inability to ensure uniform and appropriate temperature, etc., to achieve the effect of improving production efficiency and improving forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the following is based on preferred embodiments of the present invention, and is described in detail as follows in conjunction with the accompanying drawings:

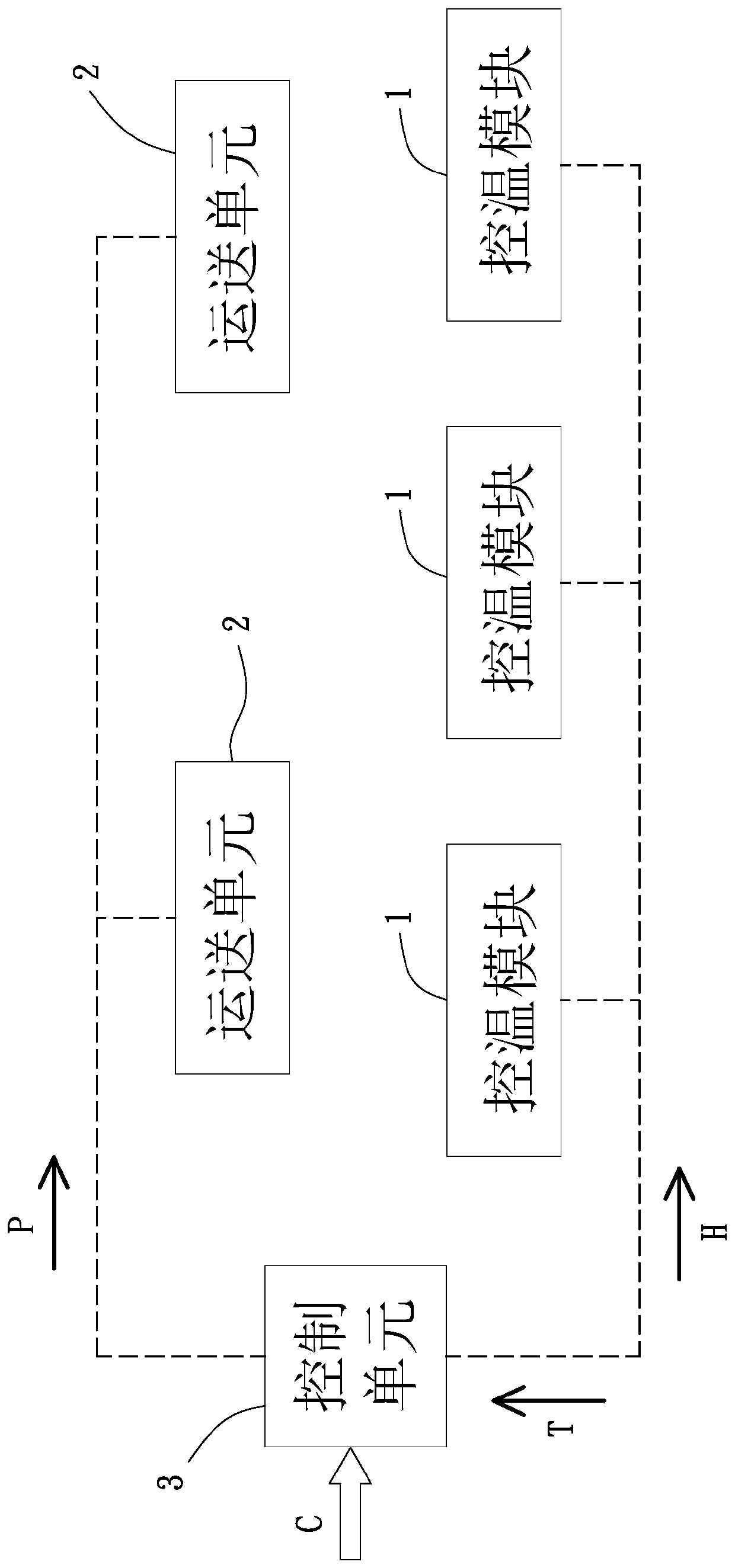

[0039] Please refer to figure 1 As shown, it is a system block diagram of a preferred embodiment of the thermoforming pre-processing system of the present invention, including at least one temperature control module 1, at least one delivery unit 2 and a control unit 3, each delivery unit 2 can be connected and To transport different temperature control modules 1 , the control unit 3 is respectively coupled to each temperature control module 1 and each transport unit 2 .

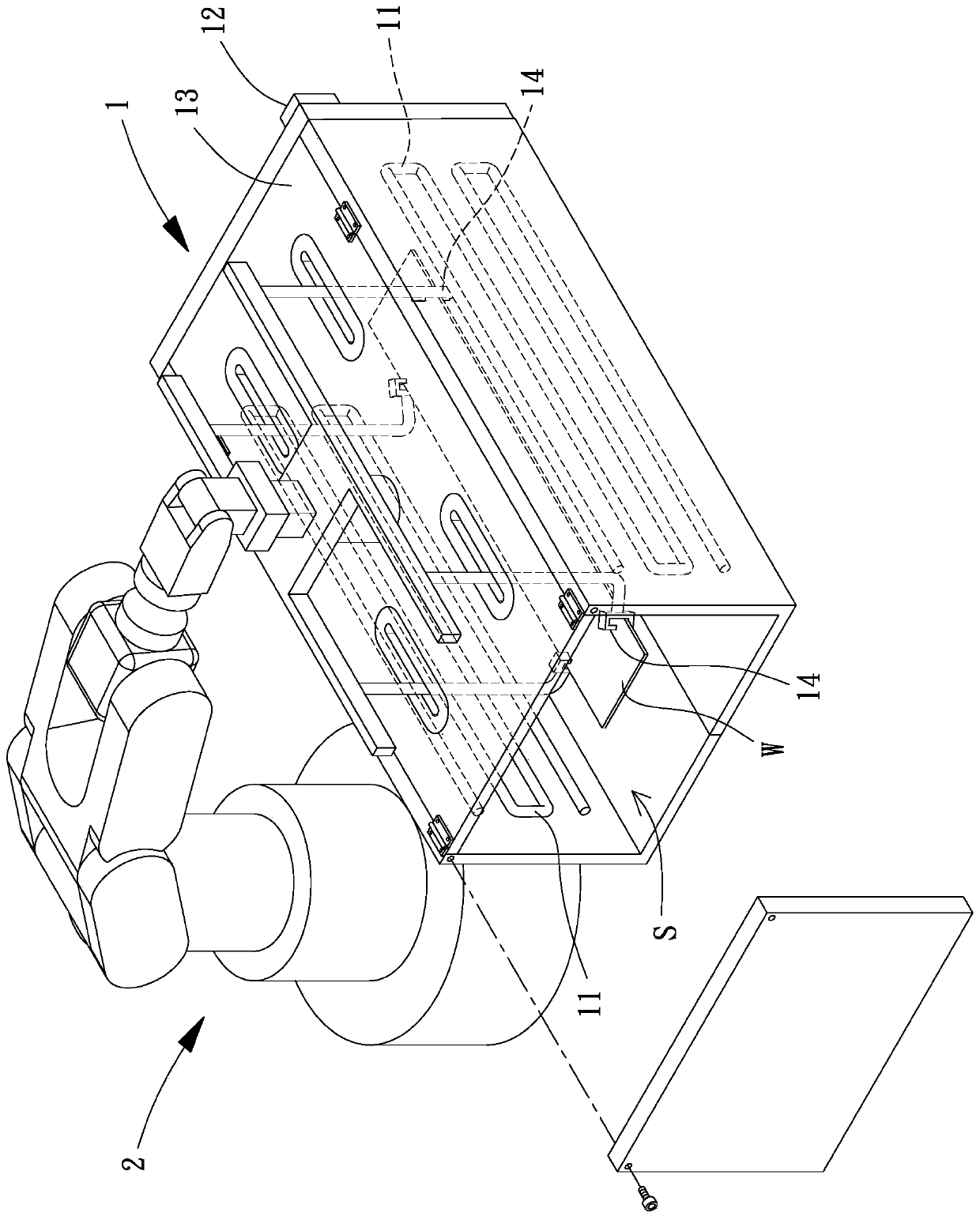

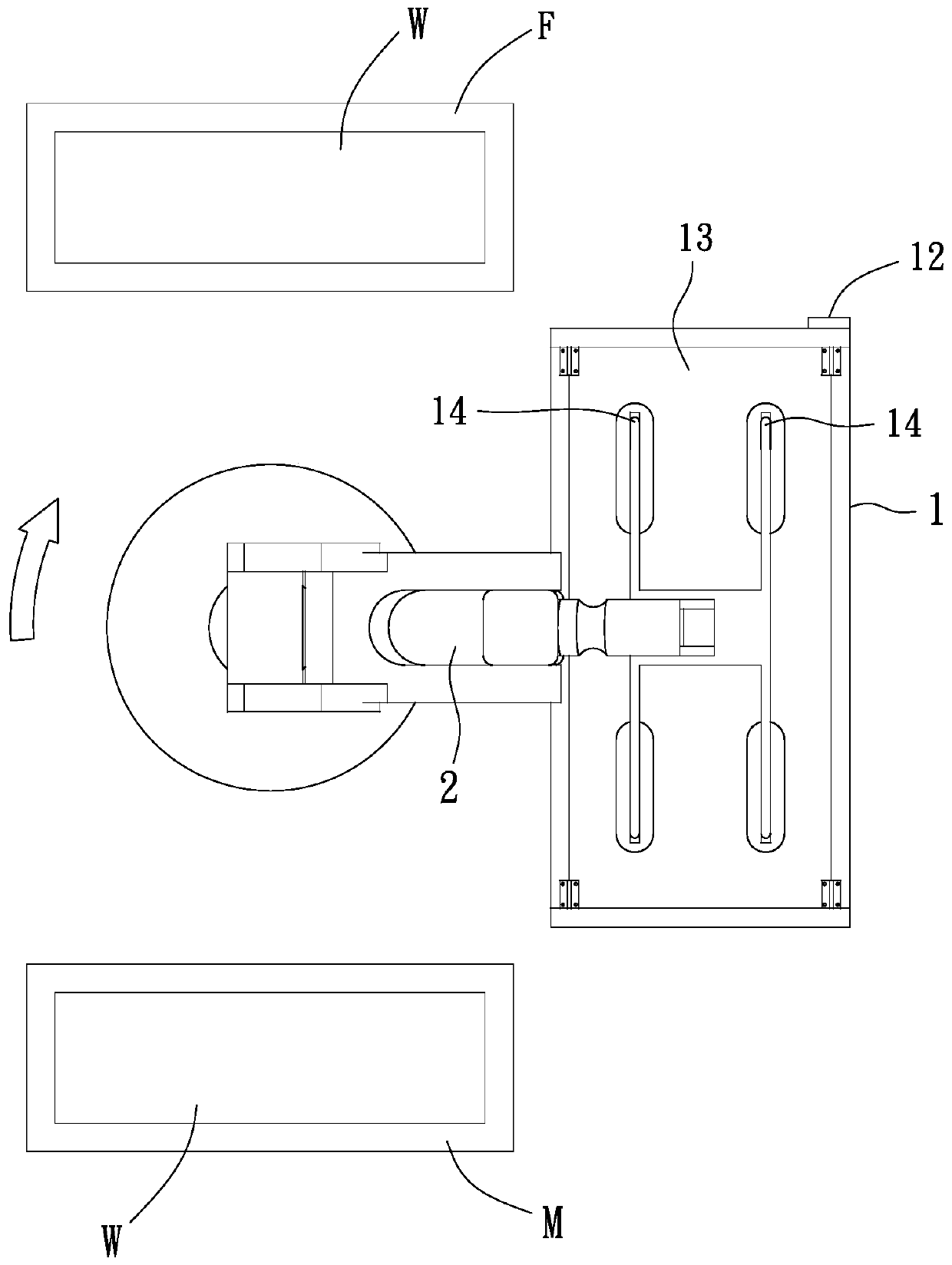

[0040] Please refer to figure 2 As shown, the temperature control module 1 has a heating unit 11, the heating unit 11 is located in an accommodating space S of the temperature control module 1, a workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com