optical components

A technology of optical components and mounting parts, which is applied in the field of optical components of vehicle lamps, can solve the problems of increased manufacturing cost and large size of optical components, and achieve the effects of improving rigidity, avoiding deformation, and improving forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

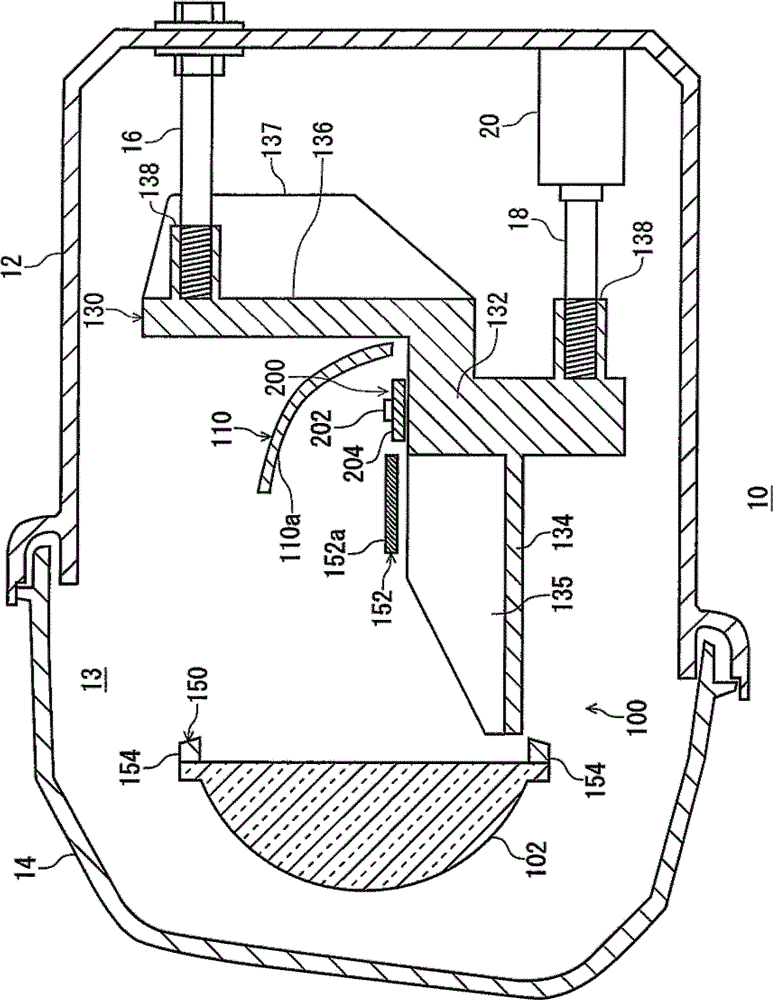

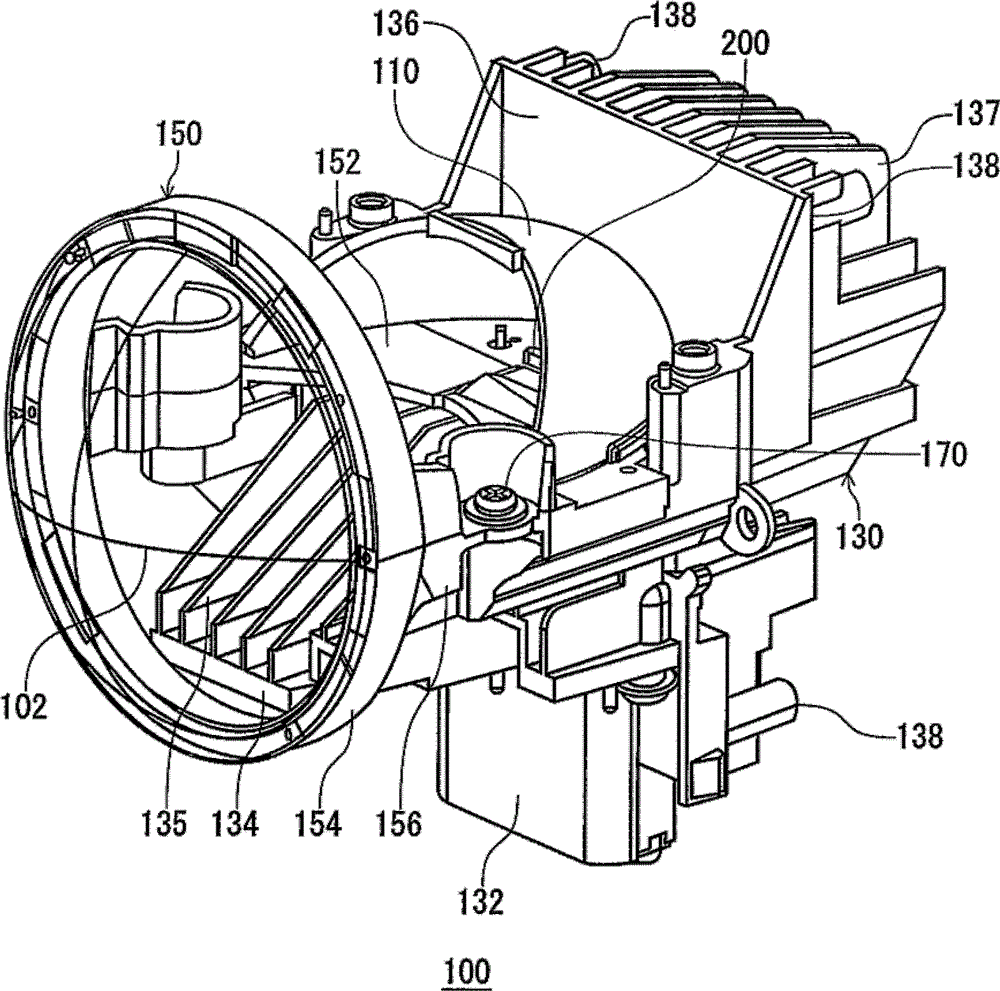

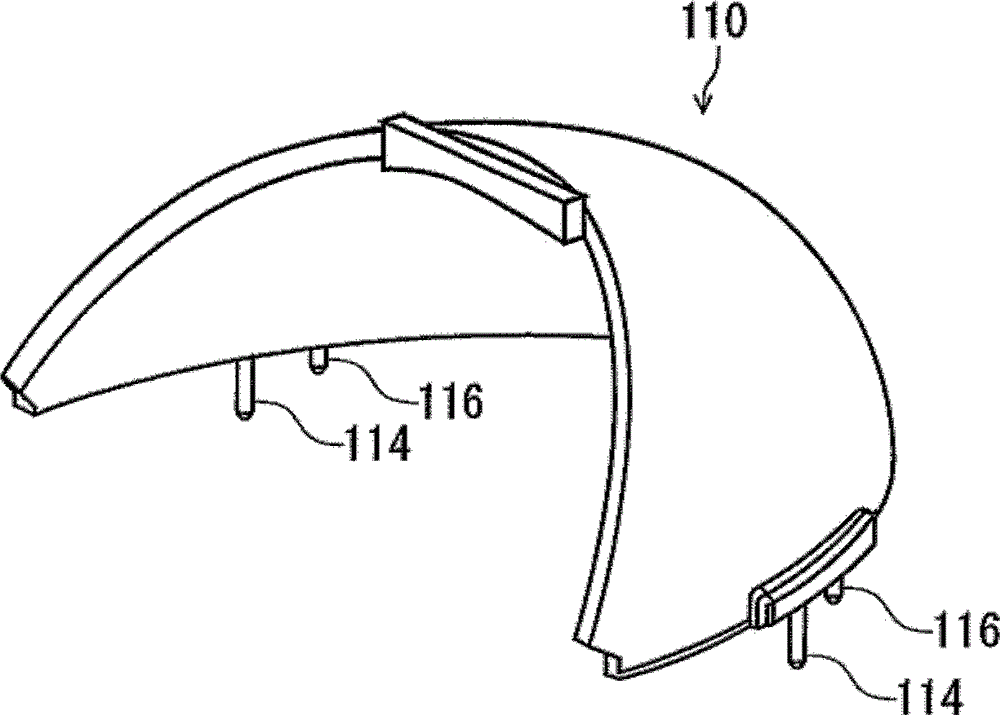

[0049] figure 1 It is a schematic partial cross-sectional view illustrating an internal structure of a vehicle headlamp device as a vehicle lamp including the optical unit of the first embodiment. figure 2 It is a schematic perspective view of the optical unit of Embodiment 1 viewed obliquely from above. In addition, the headlight device for a vehicle has a pair of headlight units formed bilaterally symmetrically. One is located on the right front part of the vehicle. figure 1 Shows the configuration of either one of the left and right headlamp units as a vehicle headlamp device.

[0050] like figure 1 As shown, the vehicle headlamp device 10 of the present embodiment includes a lamp body 12 having an opening on the vehicle front side, and a translucent cover 14 attached to cover the opening of the lamp body 12 . The translucent cover 14 is formed of translucent resin, glass, or the like. An optical assembly 100 is accommodated in a lamp chamber 13 formed by the lamp bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com