Electrode assembly of fuel cell and preparation method of electrode assembly

A technology for electrode assemblies and fuel cells, which is applied in fuel cells, battery electrodes, electrical components, etc., can solve the problems of easy deformation of CCM, ribbing of CCM, deformation and wrinkle deviation, etc., to increase mechanical strength and dimensional stability, and ensure Smoothness, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present application provides the preparation method of the above-mentioned electrode assembly of the fuel cell, which includes:

[0045] S1. Use the electrostatic adsorption force of the electrostatic auxiliary film to attach the electrostatic auxiliary film to the film layer.

[0046] S2. Remove the air in the connection area, so that a vacuum adsorption force for connecting the electrostatic auxiliary film and the film layer is formed in the connection area.

[0047] In step S2, the method of removing the air in the connection area includes: eliminating the air in the connection area by rolling or pressing, thereby causing local negative pressure to make the two more tightly combined. When rolling or pressing, it can also be heated or vacuumed at the same time to enhance the exhaust effect and better form a partial vacuum negative pressure between the interfaces to enhance the long-lasting viscosity. The persistent viscosity caused by the vacuum negative pressure...

Embodiment 1

[0054] The method for preparing the CCM sheet is:

[0055] use M815.15 proton exchange membrane (hereinafter referred to as proton exchange membrane), with a thickness of 15 μm, has a layer of 75 μm thick detachable bottom membrane.

[0056] Cut the raw material with bottom membrane into 170㎜*200㎜ sheets, which is less difficult at this time; then coat the catalyst on the side of the proton exchange membrane without the bottom membrane (that is, the first surface of the proton exchange membrane) and dried to obtain the first sample.

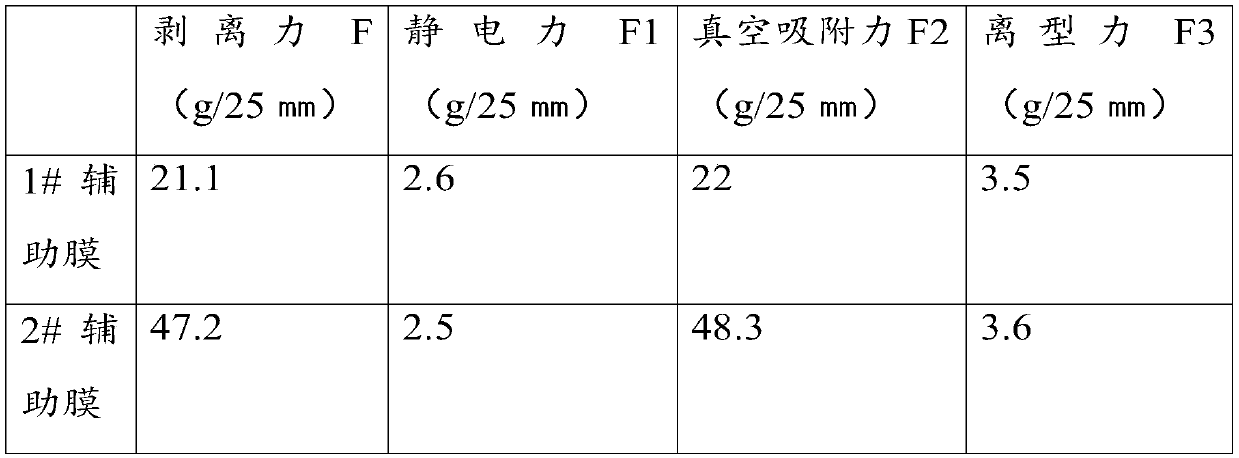

[0057] Place the first sample on a vacuum adsorption platform to smooth it out, and cover it with an electrostatic auxiliary film. The electrostatic auxiliary film is initially bonded to the side of the first sample with the catalyst through electrostatic adsorption force and formed at the joint between the two. The connection area, and then the gas in the connection area is discharged by rolling to form a vacuum adsorption force, so that the ...

Embodiment 2

[0061] The method for preparing and producing CCM coils:

[0062] use M815.15 proton exchange membrane with a thickness of 15μm and a width of 340mm. The raw material has a bottom membrane with a thickness of 75μm.

[0063] After carrying out double-sided continuous transfer printing of the proton exchange membrane, the electrostatic auxiliary membrane provided by one layer of embodiment 1 is coated on any one side before the obtained catalyst coating membrane is rolled up. Due to the existence of electrostatic adsorption force, the electrostatic auxiliary membrane can It is preliminarily attached to the proton exchange membrane and forms a connection area at the joint, and then rolls to remove the gas in the connection area. At this time, a vacuum adsorption force is formed between the proton exchange membrane and the auxiliary membrane located in the connection area, thereby making the two effective. combine together.

[0064]The winding tension is set at 30N. In the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com