Yttrium-doped lithium-rich manganese-based lithium ion battery positive electrode material, preparation method thereof and lithium ion battery

A lithium-rich manganese-based lithium and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the influence of doping effects, improve capacity decay and voltage decay problems, increase deintercalation rate, improve The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

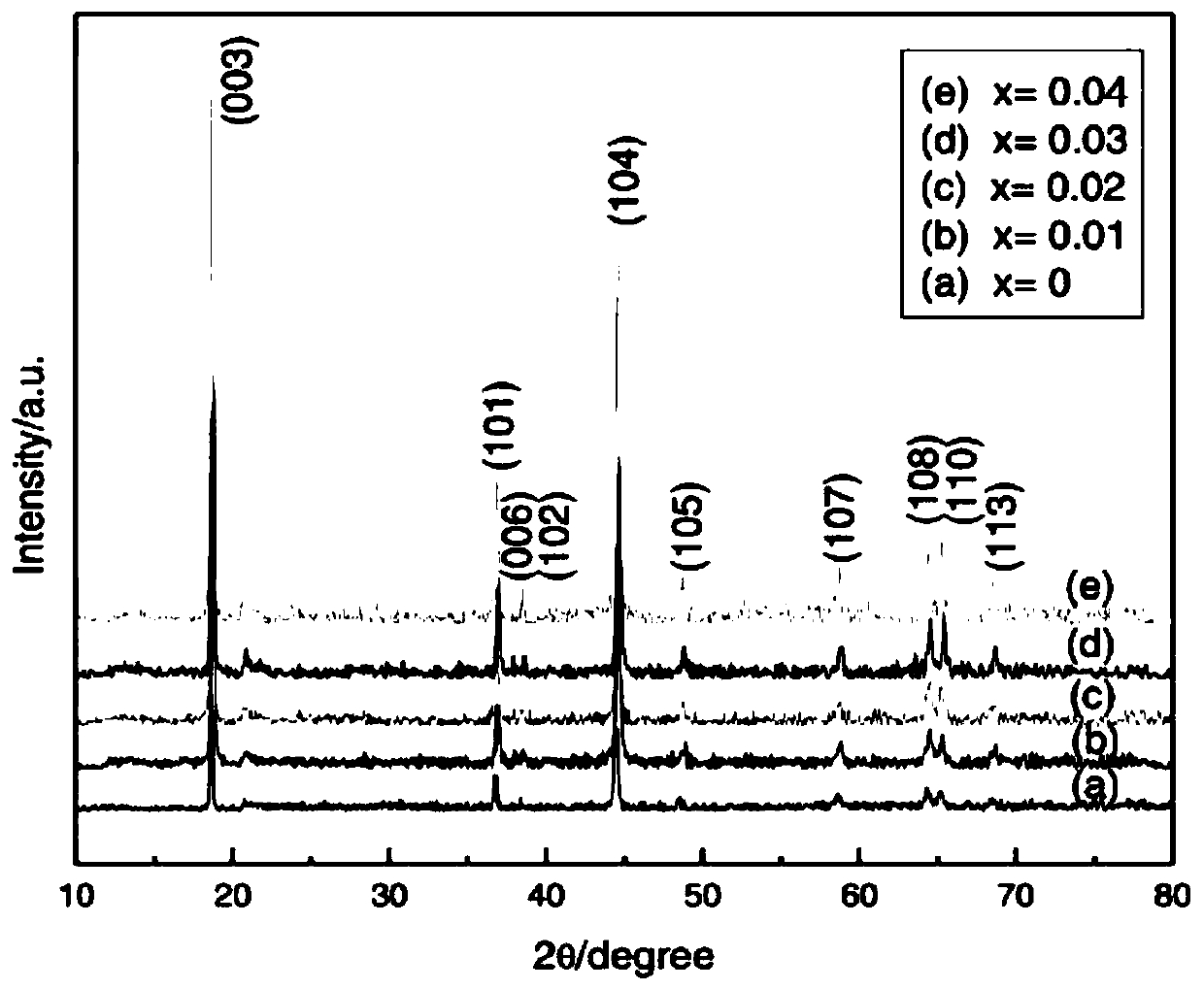

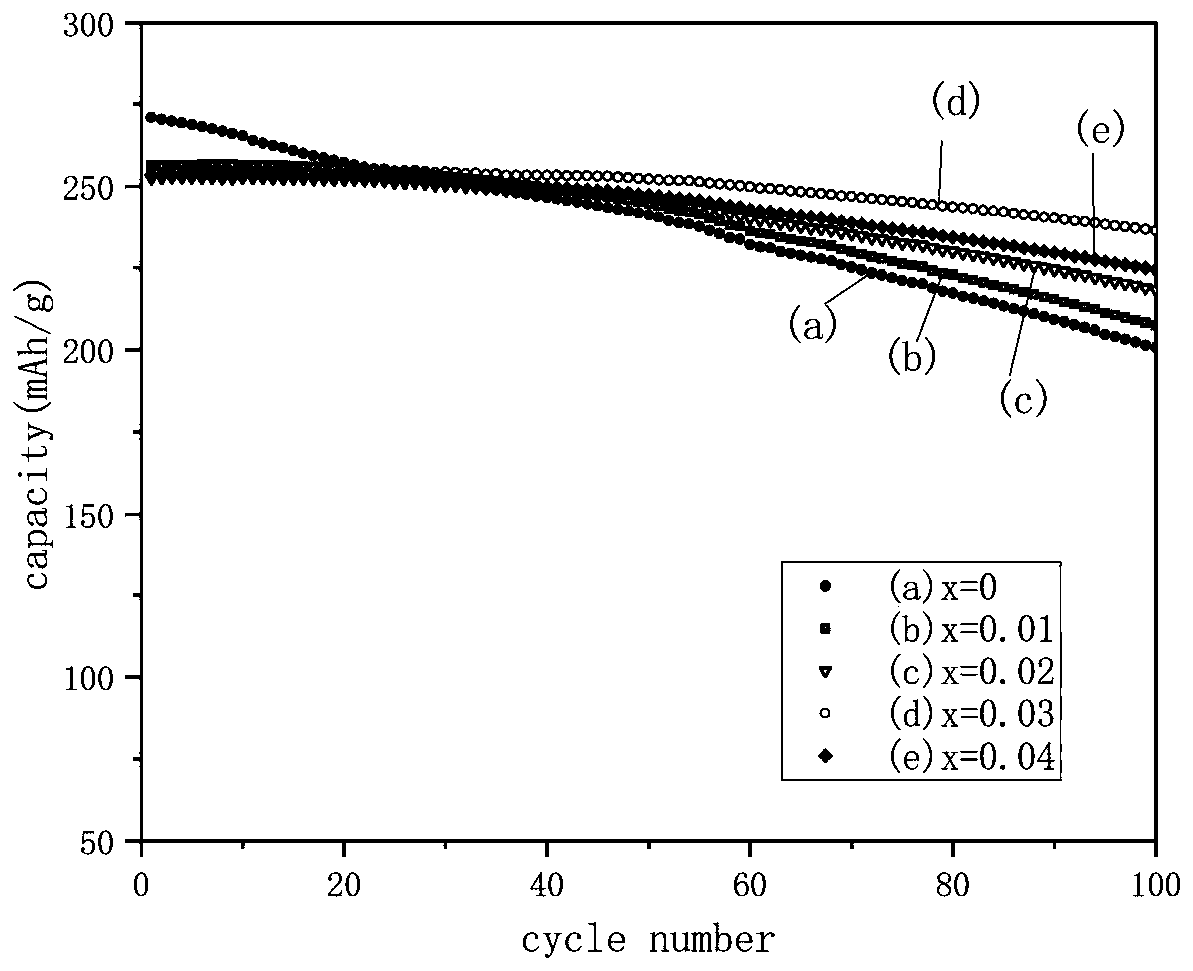

[0034] This example prepares yttrium-doped lithium-rich manganese-based cathode material Li 1.2 Ni 0.2 mn 0.57 Y 0.03 o 2 .

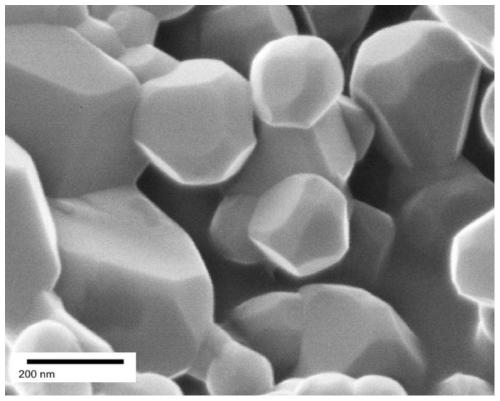

[0035] Weigh 12.852g (0.126mol) of lithium acetate dihydrate, 13.965g (0.057mol) of manganese acetate tetrahydrate, 5.816g (0.020mol) of nickel nitrate hexahydrate, 1.149g (0.003mol) of yttrium nitrate hexahydrate, mix and add 50mL Ethanol solution, heated in a water bath, and kept stirring until fully dissolved and mixed, put the liquid in a drying oven for evaporation and drying, and put the dried material in a tube furnace to heat up from room temperature at a rate of 5°C / min Pre-fired at a low temperature of 450°C for 1 hour, then raised the temperature to 900°C at a rate of 5°C / min and continued to calcine for 12 hours, and then took it out of the furnace and cooled it rapidly (cooling rate was about 20°C / min) to obtain yttrium-doped Lithium-rich manganese-based cathode materials. The sample particles prepared by this reaction are polyhedral,...

Embodiment 2

[0040] This embodiment prepares the lithium-rich manganese-based cathode material Li without doping yttrium. 1.2 Ni 0.2 mn 0.6 o 2 .

[0041] The preparation method and steps of this example are basically the same as those of Example 1, except that yttrium nitrate is not added.

[0042] After mixing the raw materials of 0.126mol lithium acetate dihydrate, 0.060mol manganese acetate tetrahydrate, and 0.020mol nickel nitrate hexahydrate, add 50mL of ethanol solution, put it in a water bath for heating, and continue to stir until it is fully dissolved and mixed. Put it into a drying oven for evaporative drying, put the dried material into a tube furnace from room temperature at a rate of 5 °C / min to 450 °C for low temperature pre-burning for 1 hour, and then at a rate of 5 °C / min to 900 °C for After calcination for 12 hours, the lithium-rich manganese-based positive electrode material without yttrium was obtained after being taken out of the furnace and cooled rapidly (coolin...

Embodiment 3

[0046] This example prepares yttrium-doped lithium-rich manganese-based cathode material Li 1.2 Ni 0.2 mn 0.59 Y 0.01 o 2 .

[0047] The preparation method and steps of this example are basically the same as those of Example 1, except that 0.001 mol of yttrium nitrate hexahydrate and 0.059 mol of manganese acetate tetrahydrate are added.

[0048] After mixing the raw materials of 0.126mol lithium acetate dihydrate, 0.059mol manganese acetate tetrahydrate, 0.001mol yttrium nitrate hexahydrate, and 0.020mol nickel nitrate hexahydrate, add 50mL ethanol solution, put into a water bath and heat, and continue to stir until Fully dissolve and mix, put the liquid into a drying oven for evaporative drying, put the dried material into a tube furnace from room temperature at a rate of 5°C / min to 450°C for 1 hour at a low temperature, and then pre-fire at a rate of 5°C / min The temperature was raised to 900° C. for 12 hours, and the yttrium-doped lithium-rich manganese-based positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com