Spiral welded pipe steel A139Gr.E with low yield ratio, and preparation method thereof

A low yield ratio, welded pipe steel technology, applied in the direction of improving process efficiency, can solve the problems of high cost of pipeline steel, high yield ratio, poor welding performance, etc., to achieve good welding performance, low yield ratio, improved The effect of welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the above-mentioned low yield ratio spiral welded pipe steel A139Gr.E, comprising the following steps:

[0033] 1) Hot metal pretreatment

[0034] Pretreat the molten iron to ensure that the mass ratio of S in the molten iron is ≤0.003%, and the slag is removed before entering the converter;

[0035] 2) Converter smelting

[0036] Concentrated scrap steel and molten iron are used for smelting, and the converter pulls carbon once and hits to avoid spot blowing; high-manganese, ferrosilicon, and ferrochrome are used for tapping, and the ladle is purged with argon before tapping to control the tapping port and avoid scattered flow. The mass content of Als in the medium is controlled at 0.025~0.045%;

[0037] 3) LF refining

[0038] The LF treatment process maintains a slight positive pressure, and the amount of N increase is ≤5ppm; LF uses activated lime and fluorite to make reducing slag, controls the intensit...

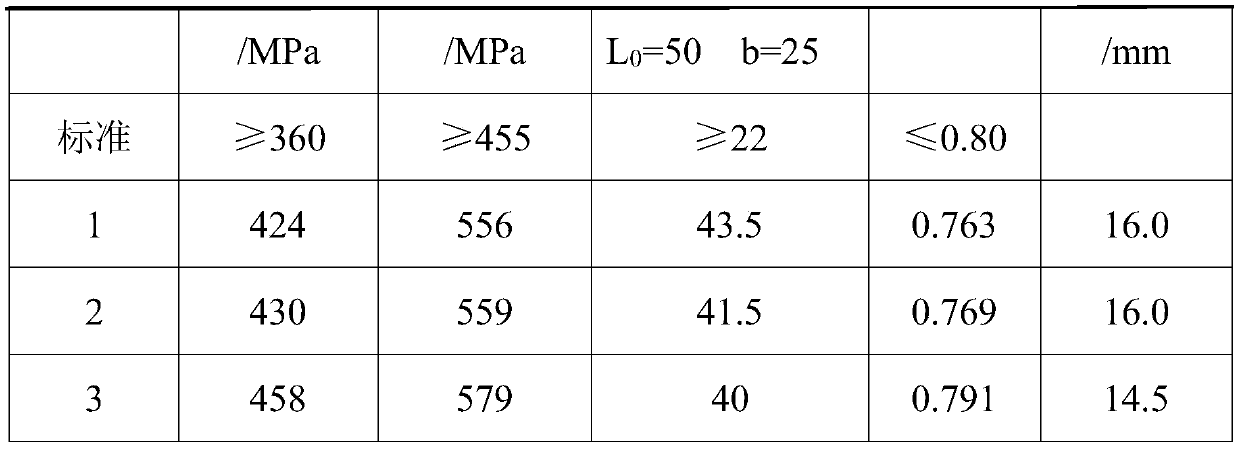

Embodiment

[0047]Prepare low yield ratio spiral welded pipe steel A139Gr.E according to the following mass percentages: C: 0.08-0.20%, Si: 0.07-0.17%, Mn: 0.90-1.40%, S: 0.001-0.005%, P: 0.005-0.015% , Cr: 0.30~0.50%, Al: 0.015~0.055%, Ca: 0.0010~0.0050%, Nb: 0.005~0.055%, Ti: 0.005~0.055%, O: 0.0010~0.0030%, the rest is Fe and other unavoidable of impurities.

[0048] The preparation method is as follows:

[0049] 1) Hot metal pretreatment

[0050] Use fine scrap steel to pretreat the molten iron to ensure that the quality of S in the molten iron entering the furnace is ≤0.003%, and the slag is removed before entering the converter;

[0051] 2) Converter smelting

[0052] Concentrated scrap steel and molten iron are used for smelting, and the converter pulls carbon once and hits to avoid spot blowing; high-manganese, ferrosilicon, and ferrochrome are used for tapping, and the ladle is purged with argon before tapping to control the tapping port and avoid scattered flow. The mass con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com